1 Clean WS6

Detailing Rottweiler

Hey all!!

I've seen a few too many "PC can't do that" threads so as an avid PC user...I'll throw my two cents in.

I am a full time pro and use a PC for 90% of my work. I do own a Makita 9227 that I do use for the total "basket cases" usually combined with Meg's 7006 pads and either Meg's #84 or #85. For me the PC is a simple, effective and safe tool that can tackle almost any job I ask of it. Unlike a rotary I never have to worry about how thin the paint on a vehicle is, catching an edge on a body line, sling or holograms...the sacrifice for that safety is time. I can say with certainty that it probably takes me twice as long to polish a vehicle with the PC than it does with a rotary but the same results can 9 times out of 10 be achieved. My simple solution on a business level is charging my customers more for in-depth details. Knowing that there won't be any "swirls" (i.e. holograms) combined with the end results of the detail have allowed me to prosper at my job for the past six years.

I in no way want you to think that I am bashing the rotary aficionados *I* just have a different preference in my choice of tools to complete my job. The purpose of this post is just my way of saying "Yes...the PC can do that". :waxing:

Here is an example of PC polishing on an '03 Mustang Cobra that I recently detailed. As you can see the paint was trashed...bonded contaminants galor and heavy marring. All polishing was done with a PC 7424 with a 6oz counter weight and 6" backing plate. Pads were LC orange for IP; LC white for FPII; LC black for VM and Meg's 9006 for CMW.

Before (after wash and clay)...

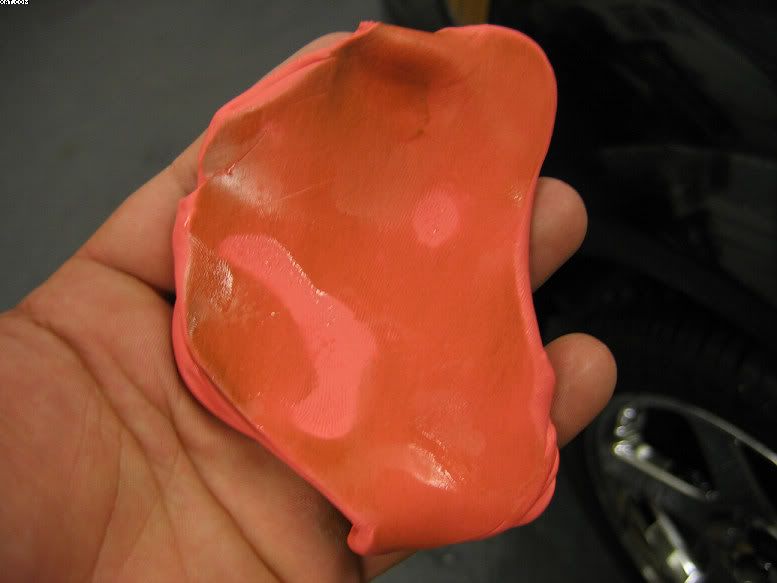

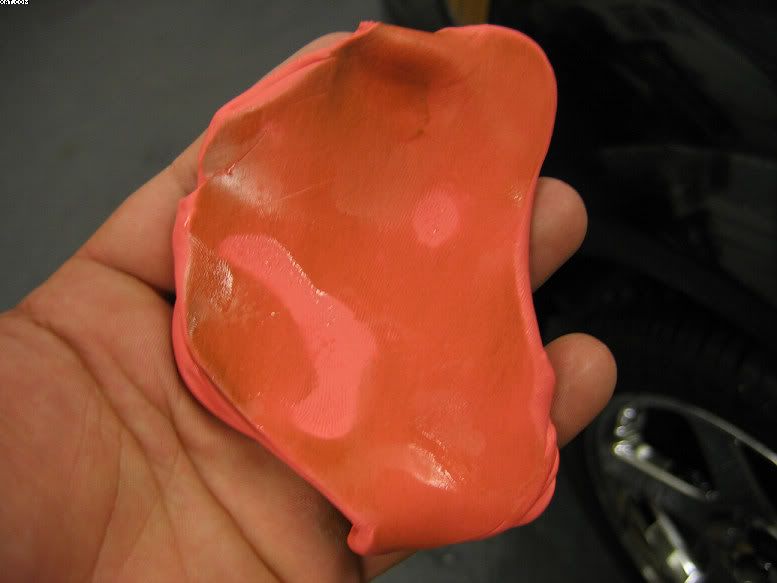

Clay after just one panel...

I've seen a few too many "PC can't do that" threads so as an avid PC user...I'll throw my two cents in.

I am a full time pro and use a PC for 90% of my work. I do own a Makita 9227 that I do use for the total "basket cases" usually combined with Meg's 7006 pads and either Meg's #84 or #85. For me the PC is a simple, effective and safe tool that can tackle almost any job I ask of it. Unlike a rotary I never have to worry about how thin the paint on a vehicle is, catching an edge on a body line, sling or holograms...the sacrifice for that safety is time. I can say with certainty that it probably takes me twice as long to polish a vehicle with the PC than it does with a rotary but the same results can 9 times out of 10 be achieved. My simple solution on a business level is charging my customers more for in-depth details. Knowing that there won't be any "swirls" (i.e. holograms) combined with the end results of the detail have allowed me to prosper at my job for the past six years.

I in no way want you to think that I am bashing the rotary aficionados *I* just have a different preference in my choice of tools to complete my job. The purpose of this post is just my way of saying "Yes...the PC can do that". :waxing:

Here is an example of PC polishing on an '03 Mustang Cobra that I recently detailed. As you can see the paint was trashed...bonded contaminants galor and heavy marring. All polishing was done with a PC 7424 with a 6oz counter weight and 6" backing plate. Pads were LC orange for IP; LC white for FPII; LC black for VM and Meg's 9006 for CMW.

Before (after wash and clay)...

Clay after just one panel...