Kevin Brown

New member

CEE DOG said:...As for the towel and pad analogy I would disagree that it's a fair comparison. What I am saying is the edge of the pad is not more contaminated in the manner theoretically suggested. If it was we would find a different end result which I do not see. Perhaps it is due to a completely different technique, tools, etc. but I don't see it. Rather it seems all the particles including polish and paint are cut to a size that does not affect the finish and are evenly pressed into the pad pores or dust off away from the surface. As long as it's made clean after each section there isn't an issue and the finish can be flawless in the real world regardless of theory.

Thank you,

Corey

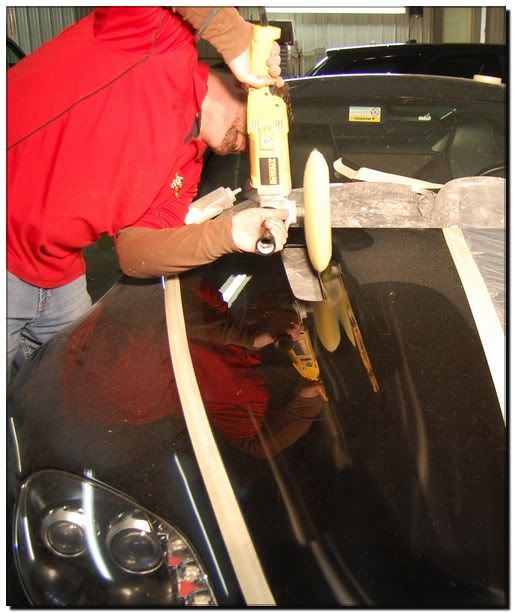

It is typical to see the edge of a buffing pad become more laden with particulate. Unless you're throwing some tilt on the pad like you might commonly do using a rotary polisher. Okay, maybe a lot of tilt.

Having too much fun while you buff?!? Are you "popping" one-way buffing pad "wheelies", and the actual "trailing edge" of your pad is underneath the pad face? :clap2: I'm not sure what was lost in the translation. :nixweiss