imported_Dave KG

New member

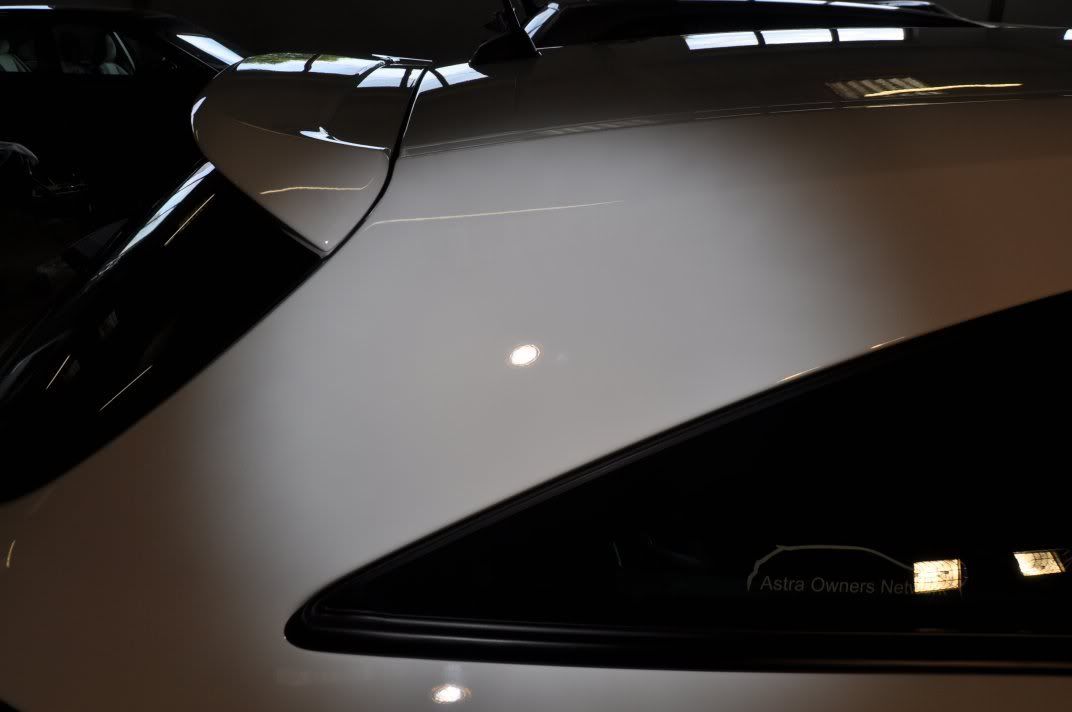

The subject of Saturday's tuition detail, this Vauxhall Astra Sport Hatch...

The car is owned by Helen, MissyR on the forum, who is already experienced with a DA polisher but fancied learning how to use the rotary Gordon (caledonia) was also along for the day to help out, huge thanks to Gordon for his assistance on the day - very enjoyable team detailing today :thumb:

Gordon (caledonia) was also along for the day to help out, huge thanks to Gordon for his assistance on the day - very enjoyable team detailing today :thumb:

Starting off with the wheels and arches, Bilberry Wheel Cleaner was used, with All Purpose Cleaner from Meguiars used on the tyres and arches. This was before the car was foamed using Meguiars Shampoo Plus through the foam lance...

After washing the car using Shampoo Plus and the two bucker wash method, it was clayed using Bilt Hamber Soft Clay. The car had clearly been clayed quite recently, the paint aleady very smooth and only the odd bit here and there being lifted off the paint.

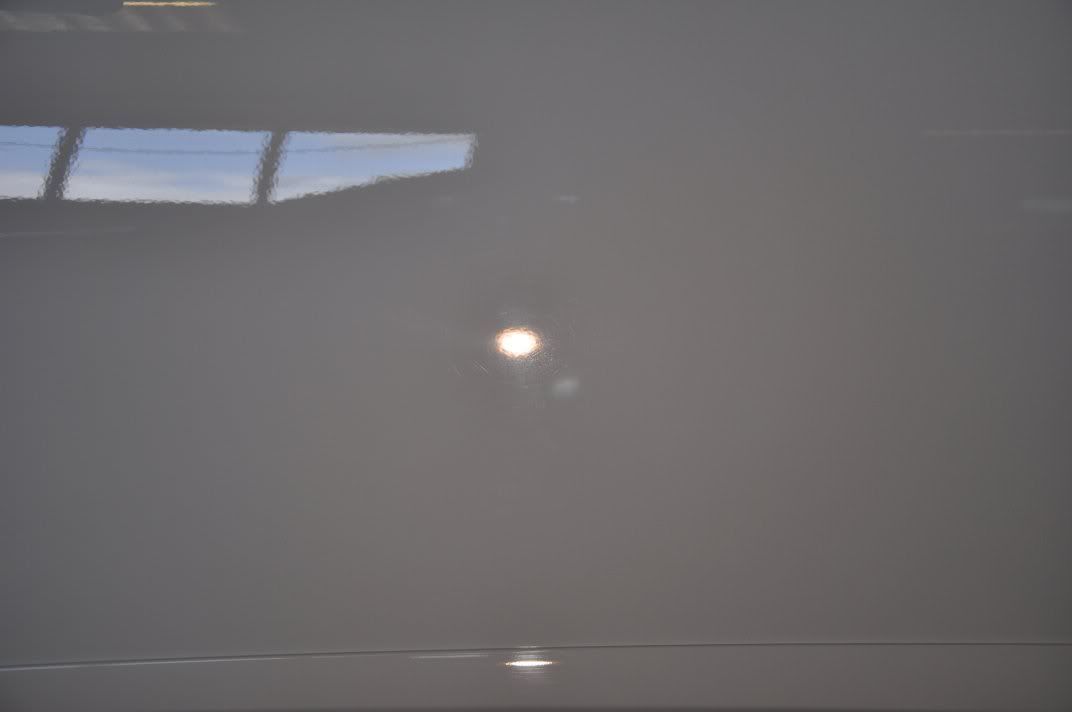

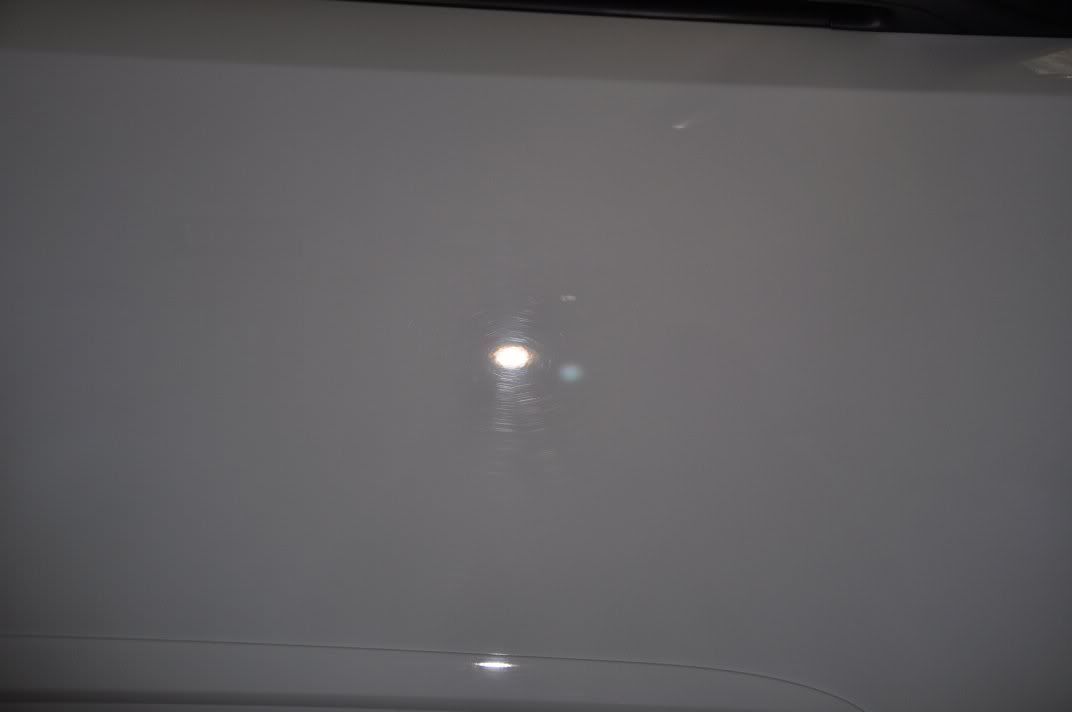

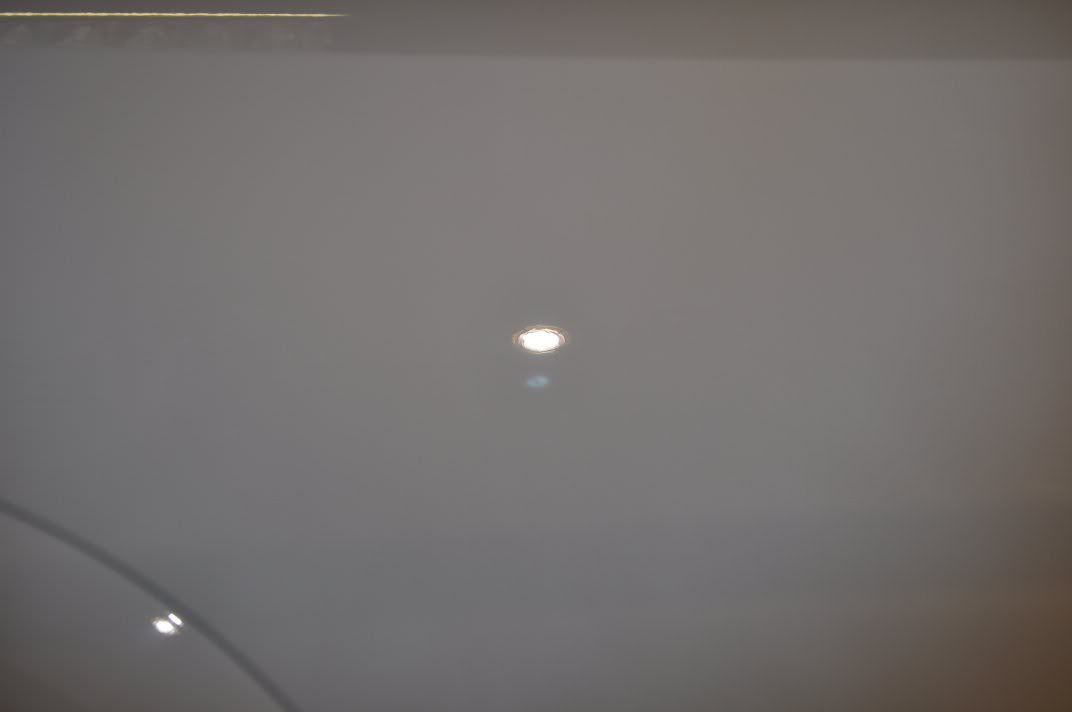

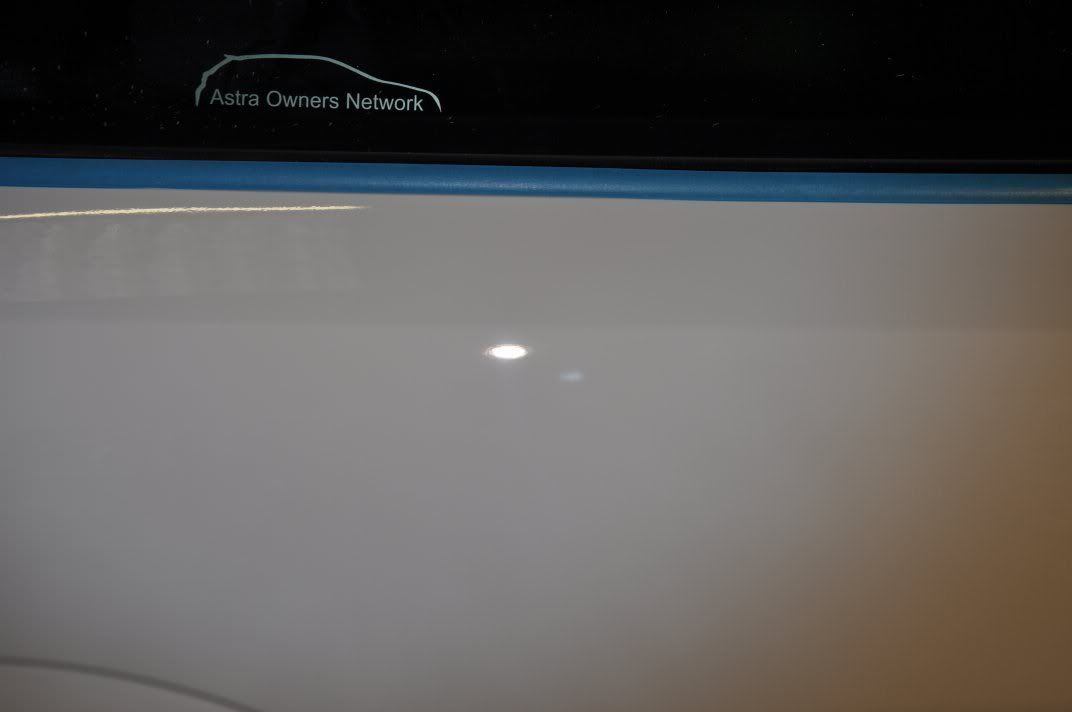

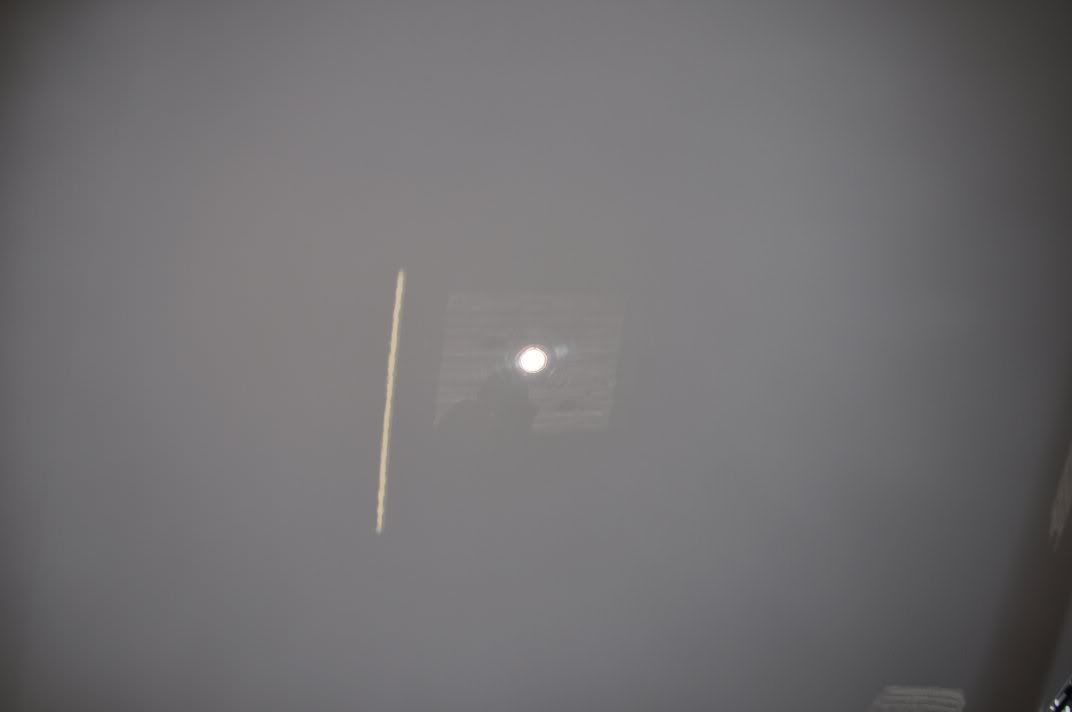

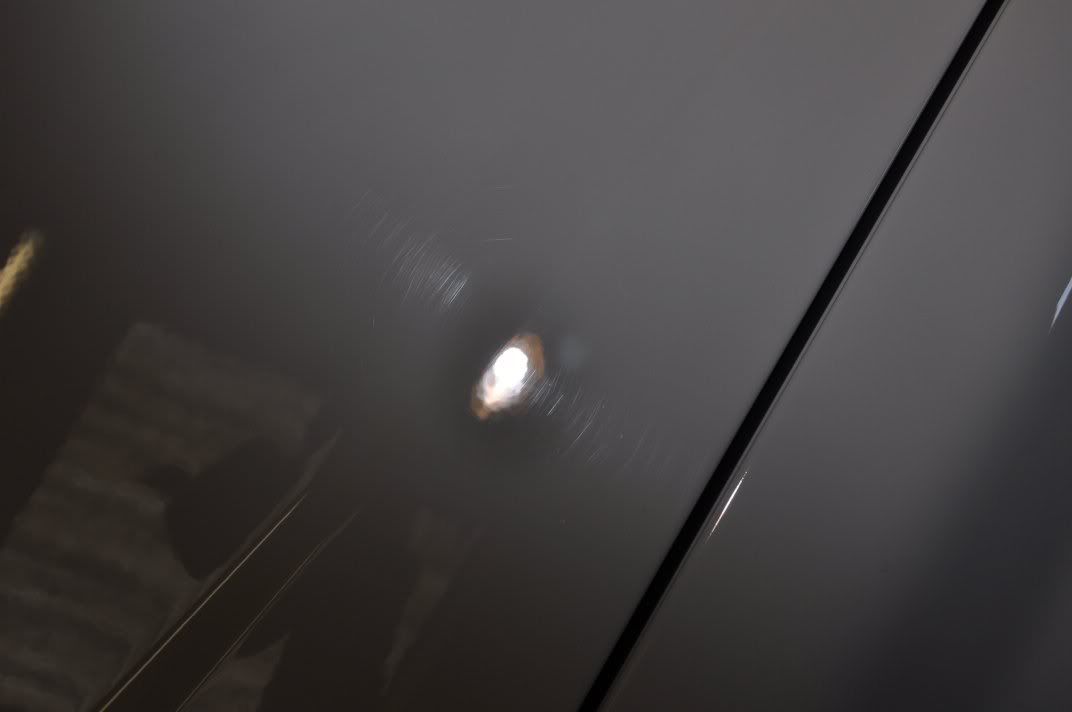

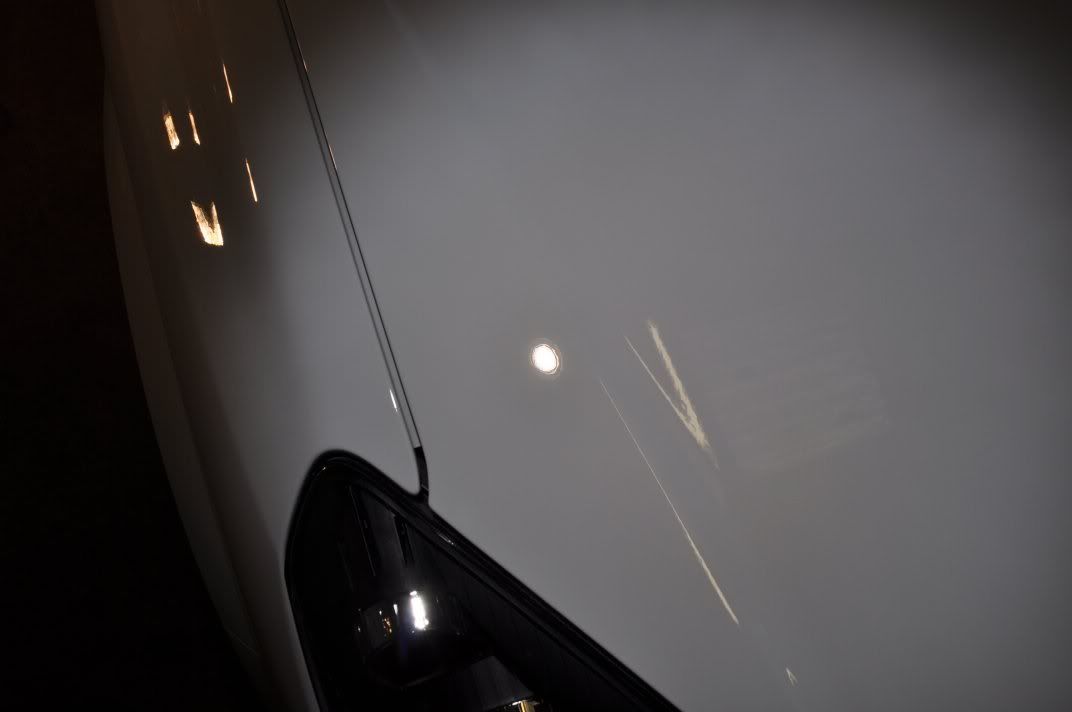

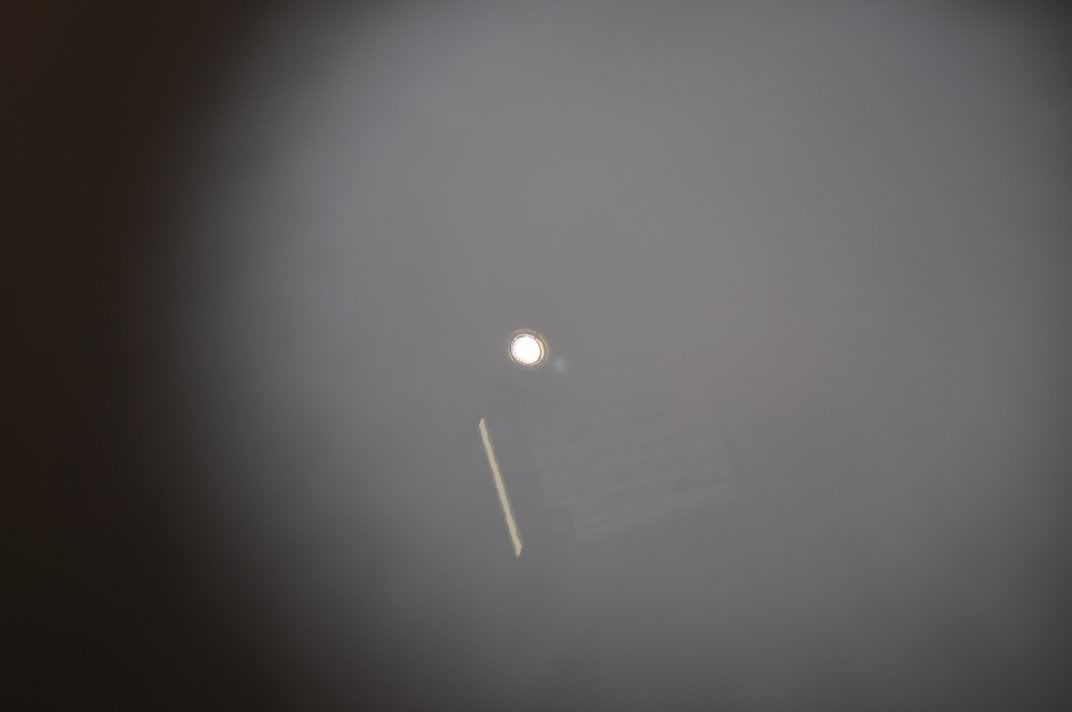

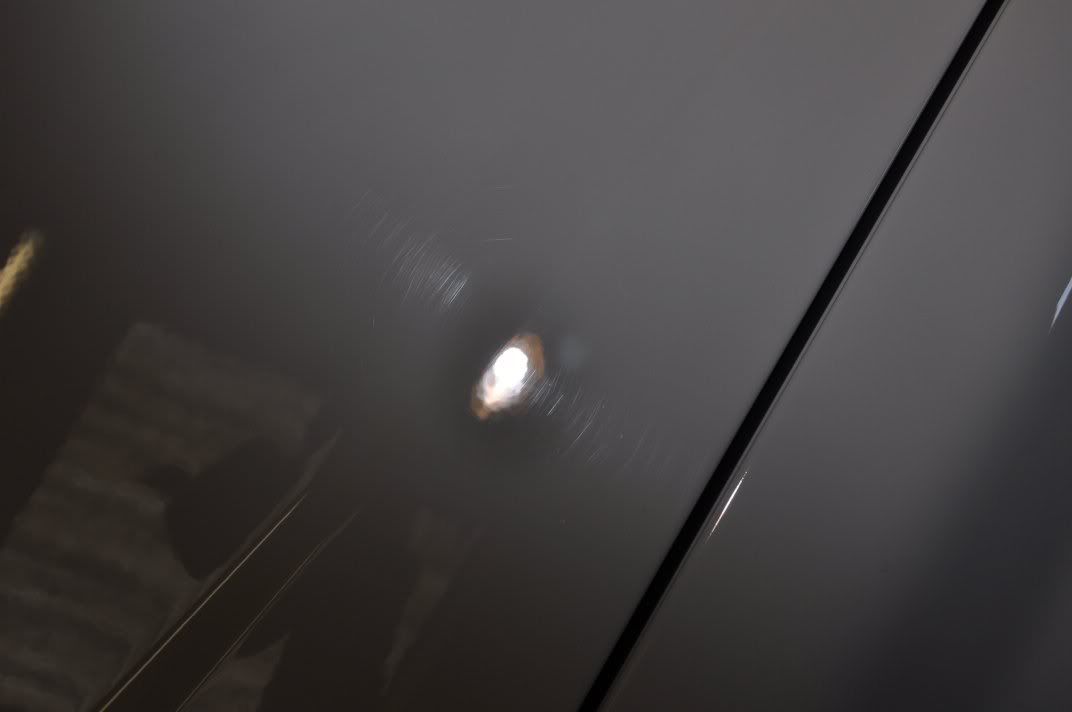

With the car cleaned, and clayed, we could now assess the finish... the swirls were there, but they were very light...

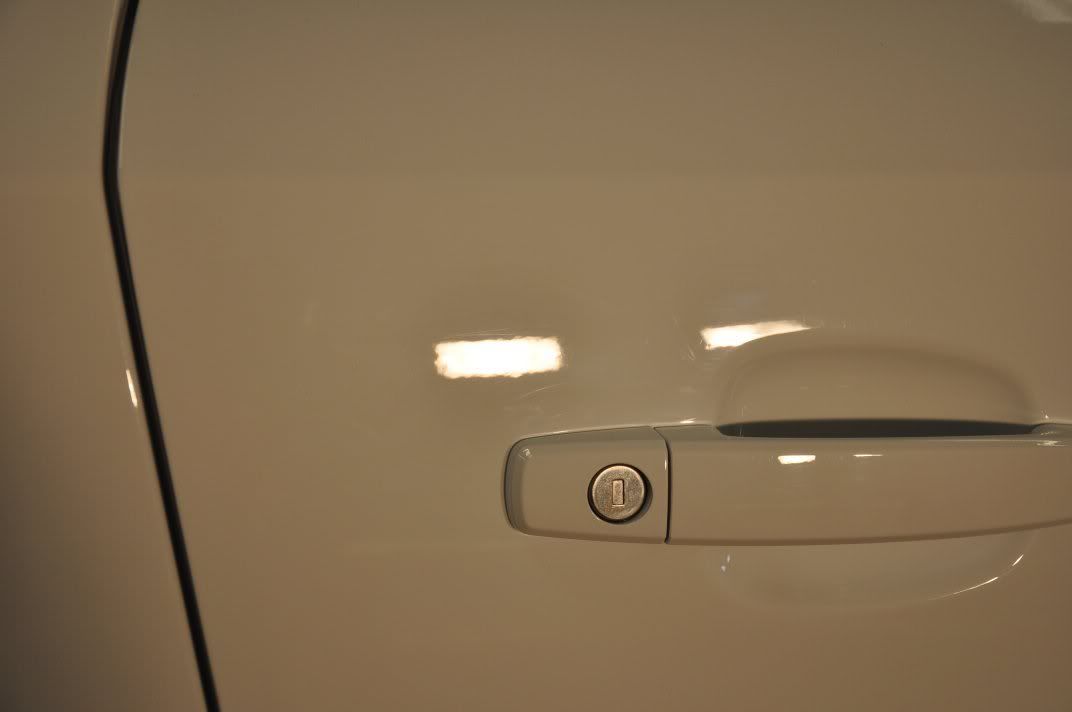

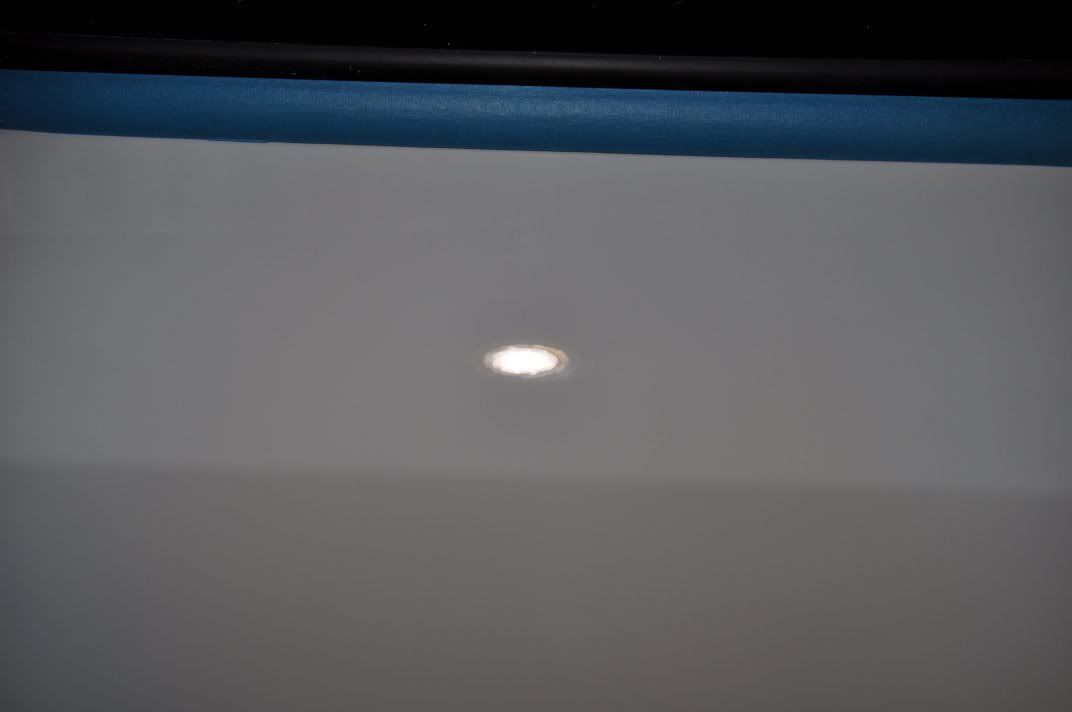

While Helen and I worked on the test car for rotary tuition, Gordon got started on the rear of the car...

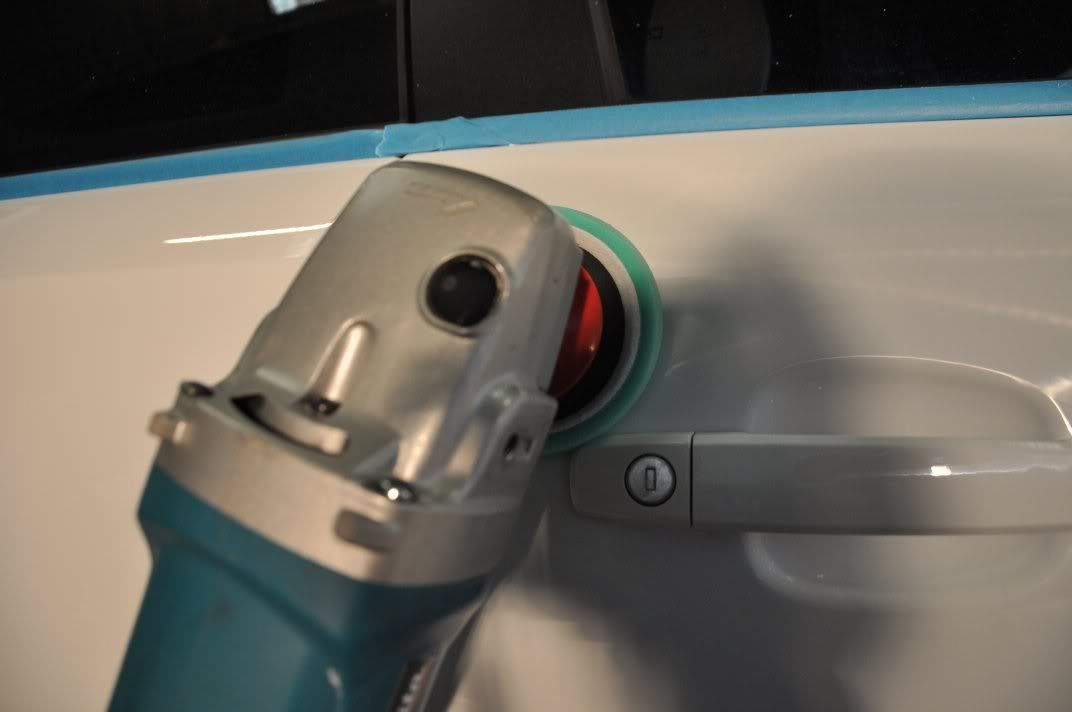

Once Helen was happy with the control of the rotary on the test car, it was time for her to tackle her bonnet... I stepped up first, assessing the paint finish and what was going to achieve the results and explaining the process of product choice as I went. A light finishing polish was knocking out all of the swirls but leaving some RDS in the finish. In the end, we decided on Menzerna PO85RD3.02 Intensive Polish applied by rotary using a Meguiars W8006 polishing pad, using a "correction-only" technique as follows:

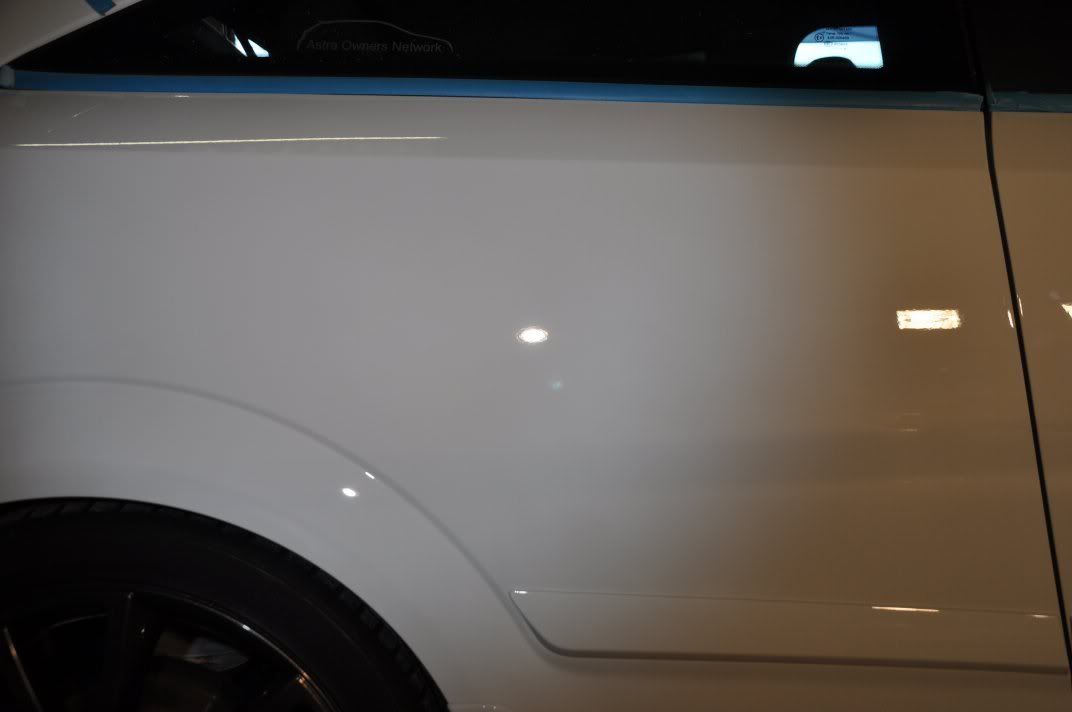

No attempt at refining was made here. Instead, we used a dedicated finishing stage: Meguiars #205 Ultra Finishing Polish on a Meguiars W9006 tan finishing pad. Quite a polish this new finishing polish from Meguiars, using unigrit technology it remains abrasive till the end of the set but you can vary the cut by varying the pressure you apply to the pad (as well as the pad itself...). For finishing purposes, we have used a finishing pad. Product applied as follows:

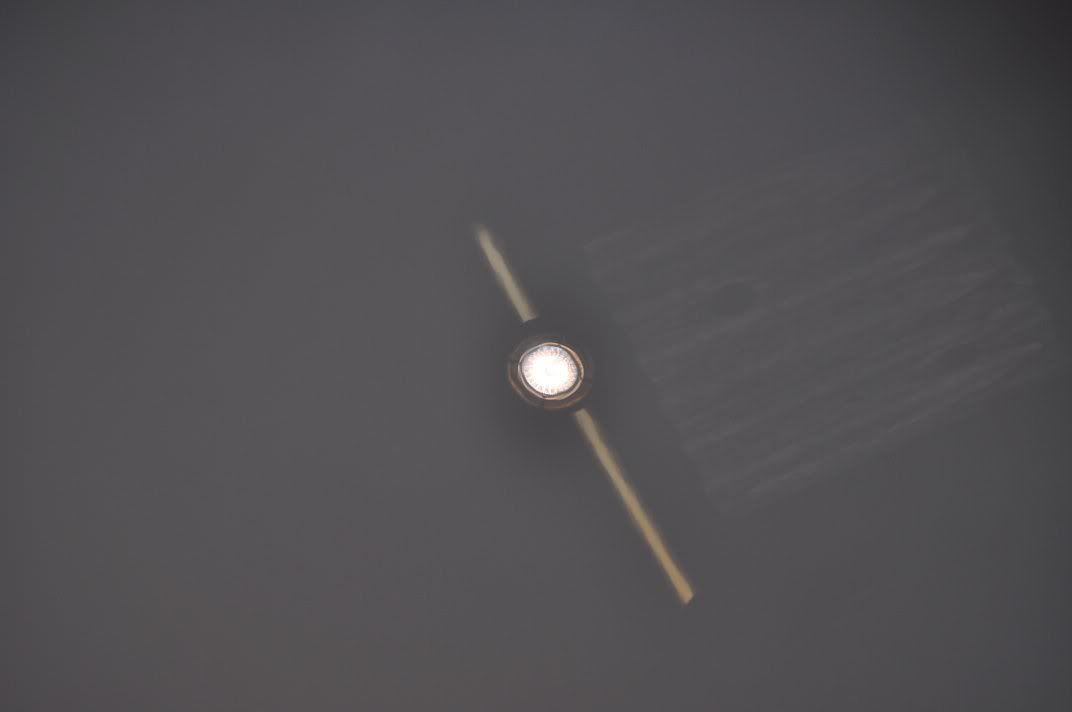

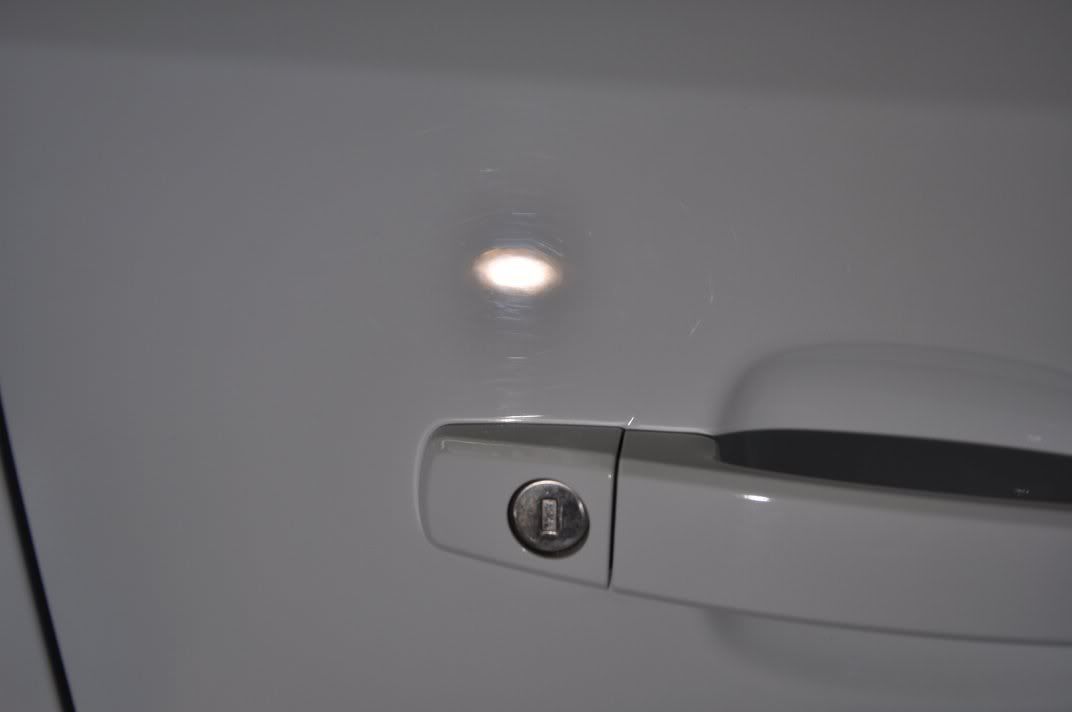

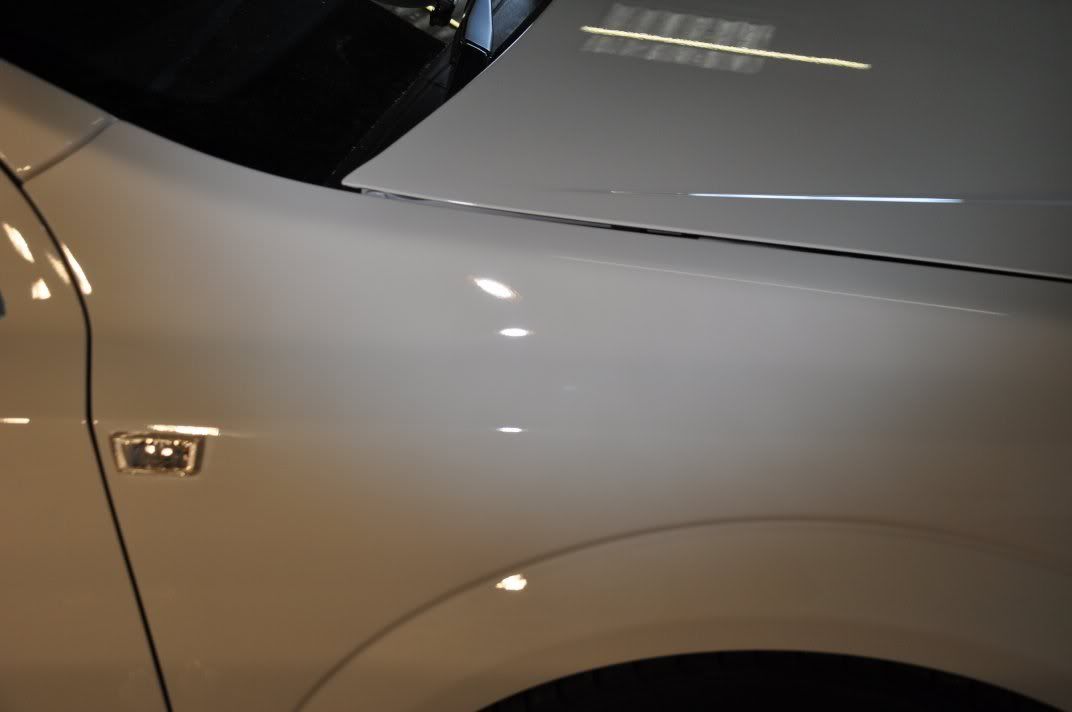

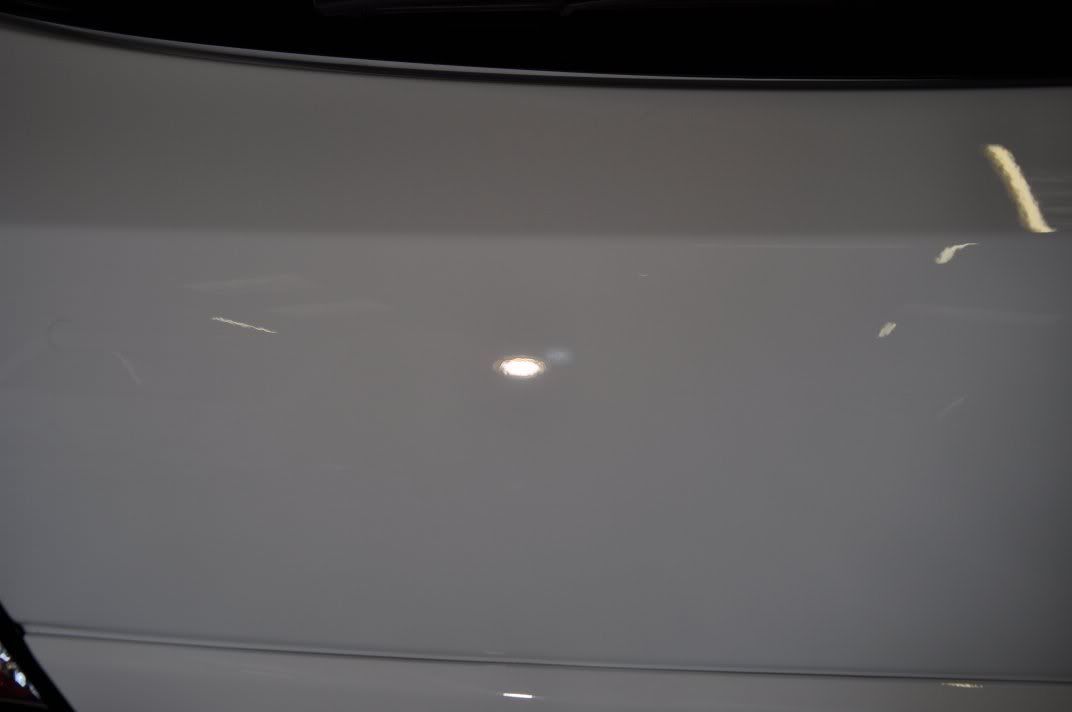

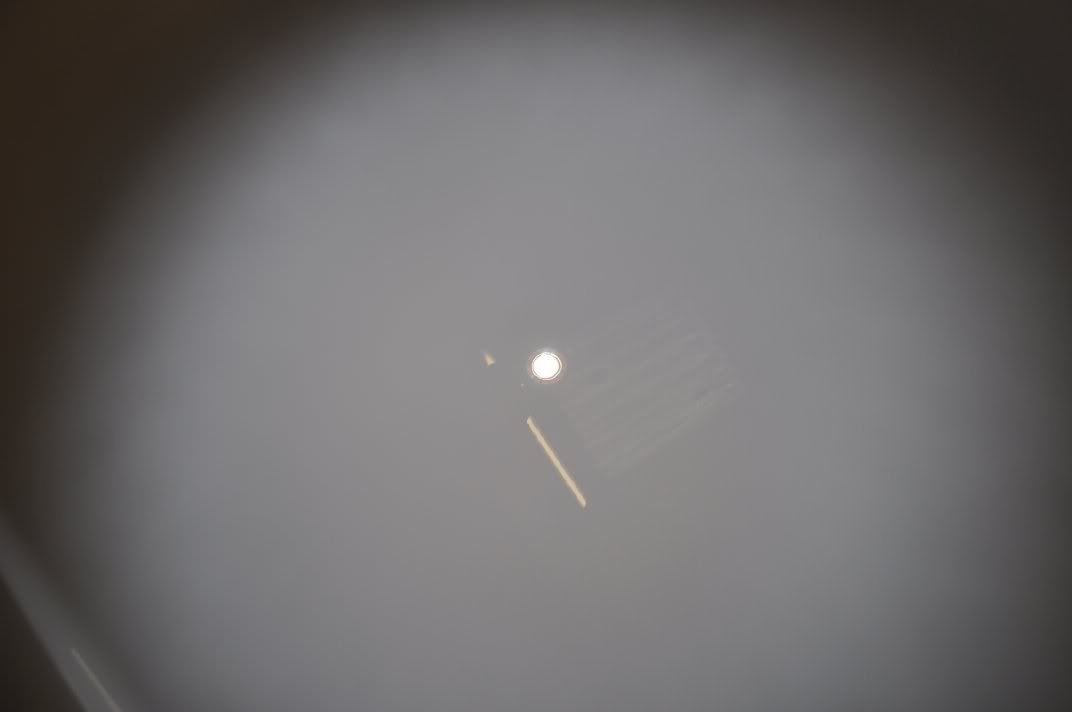

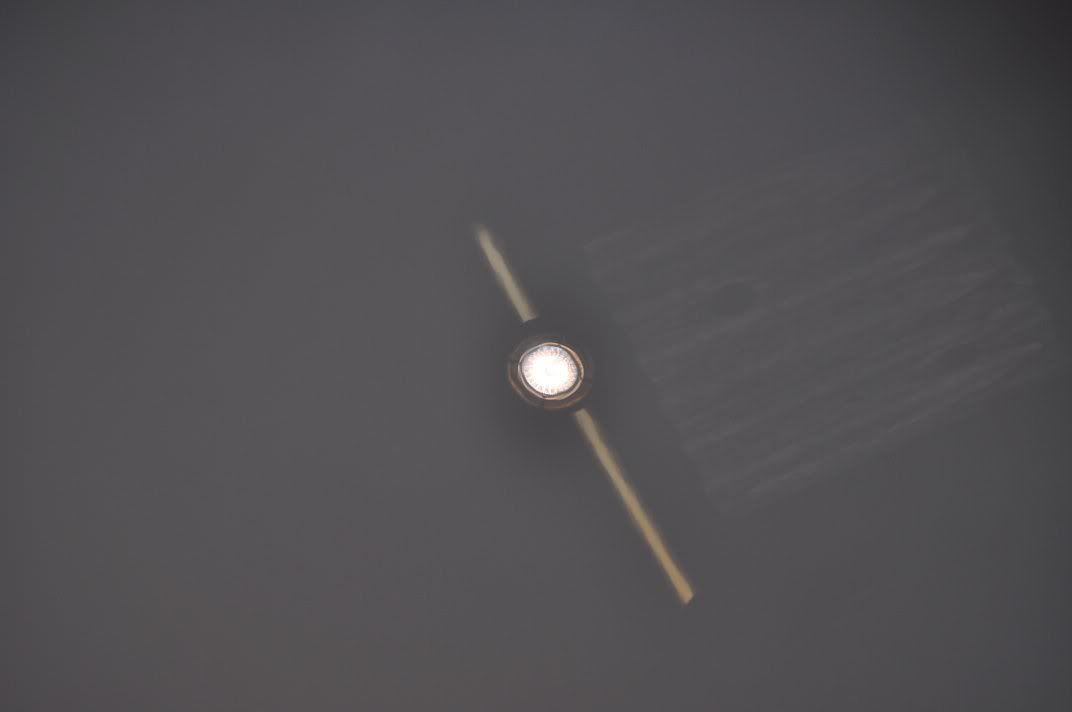

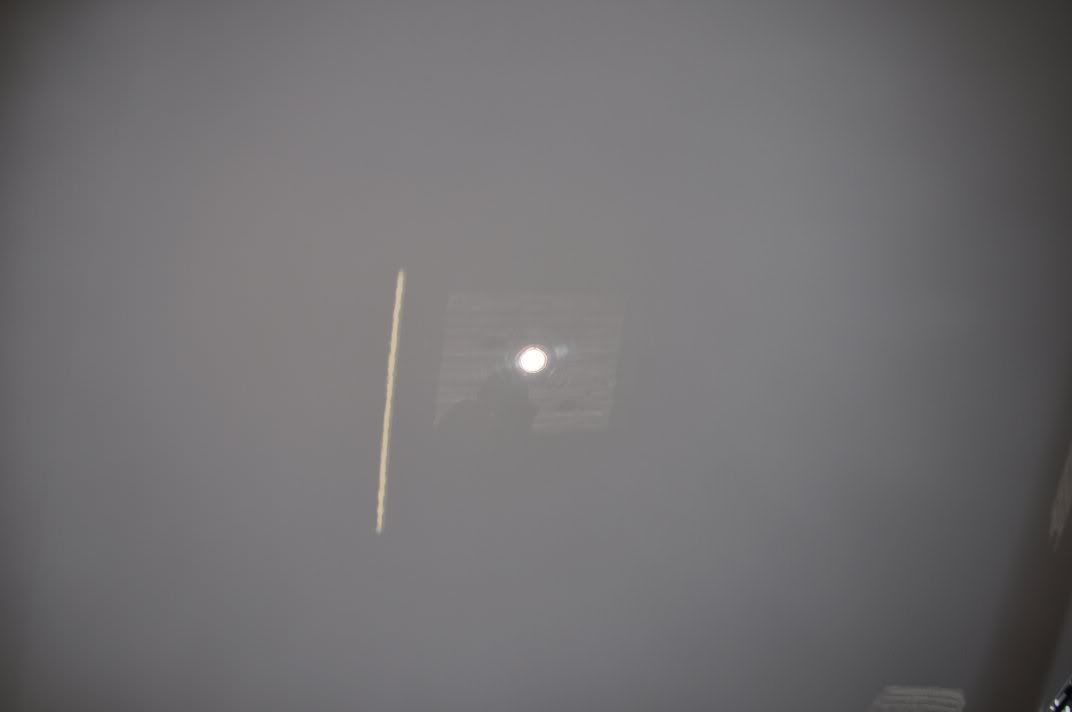

The end result of this process:

The car is owned by Helen, MissyR on the forum, who is already experienced with a DA polisher but fancied learning how to use the rotary

Starting off with the wheels and arches, Bilberry Wheel Cleaner was used, with All Purpose Cleaner from Meguiars used on the tyres and arches. This was before the car was foamed using Meguiars Shampoo Plus through the foam lance...

After washing the car using Shampoo Plus and the two bucker wash method, it was clayed using Bilt Hamber Soft Clay. The car had clearly been clayed quite recently, the paint aleady very smooth and only the odd bit here and there being lifted off the paint.

With the car cleaned, and clayed, we could now assess the finish... the swirls were there, but they were very light...

While Helen and I worked on the test car for rotary tuition, Gordon got started on the rear of the car...

Once Helen was happy with the control of the rotary on the test car, it was time for her to tackle her bonnet... I stepped up first, assessing the paint finish and what was going to achieve the results and explaining the process of product choice as I went. A light finishing polish was knocking out all of the swirls but leaving some RDS in the finish. In the end, we decided on Menzerna PO85RD3.02 Intensive Polish applied by rotary using a Meguiars W8006 polishing pad, using a "correction-only" technique as follows:

- Spread at 600rpm

- Begin working at 1200rpm

- Work at 1500 - 1800rpm until defects corrected

No attempt at refining was made here. Instead, we used a dedicated finishing stage: Meguiars #205 Ultra Finishing Polish on a Meguiars W9006 tan finishing pad. Quite a polish this new finishing polish from Meguiars, using unigrit technology it remains abrasive till the end of the set but you can vary the cut by varying the pressure you apply to the pad (as well as the pad itself...). For finishing purposes, we have used a finishing pad. Product applied as follows:

- Spread at 600rpm, light pressure

- Begin working at 1200rpm, light pressure

- Work at 1500rpm for a couple of minutes, moderate pressure, until the residue goes clear

- Refine at 900rpm, light pressure to burnish to a gloss

The end result of this process: