Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sharing the knowledge as I learn it...

- Thread starter danponjican

- Start date

SuperBee364

New member

kleraudio said:I thought wool was DANGEROUS! Seems Coupe and David F. are bringing it back. Coupe I remember when you were just starting to inquire about wool, now look at ya!

Im really surprised about this whole wool movement on here, Ive always been under the impression that wool pads are really really dangerous.

How much more clear do you remove when using wool compared to foam?

I am seriously considering wool now after all Ive heard around here!

Jim

Yeah, it seems like everyone is a bit afraid of wool. I think it's because most people think of wool in terms of the nastiest wool; the 100% wool double-twisted cutting pad. While that pad is one nasty hombre, there are also wool pads in every cut available, all the way down to the finest polishing pad.

As Coupe mentioned, not only does wool stay cooler, but I really like the way wool does it's job fast. I don't like to have to pack a lunch and take vacation time from work to polish a car. Wool pads (in whatever aggressiveness you're using) do their job so much faster than foam it's amazing. And as Coupe mentioned, they are so much easier to control. The Edge line is wonderful, and I also really love LC's purple foamed wool for correction. More so than the yellow edge one, actually.

Yesterday was the first time I tried the blue and the white wool final polishing pads. I used the blue first, then went over it with the white just to see if there was any improvement. There wasn't any that I could tell; the blue pad brought up an amazing shine in no time.

I just can't imagine anyone that does this full time not using edge/presta wool, they are that much faster. They are also very easy to clean up afterward, too. Quick dunk in the snappy pad cleaner, then attach to the buffer, spur it a bit, then run it up to the max allowed RPM of 2500. Pad is clean and dry in no time.

kleraudio said:Well If its working why use anything else??

I think Im gonna call up AG and order some egde wool. Its got a hole in the middle to use with the adapter right? Or is it hook and loop backing?

So you recommend the yellow and green wool? Im gonna use 6 inch I think.

Jim

Yup, just ask for double sided. Be specific that your using the edge2k system becuase they do make tradiotinal hook and loop also.

kleraudio said:A question for those who watched the videos that were linked from this post.....

He showed the yellow wool pad and it was dirty, then it faded to black and voila, it was clean!!

What did he use to clean it so damn fast? That would be nice to know!

Jim

Which video?

Coupe said:Yup, just ask for double sided. Be specific that your using the edge2k system becuase they do make tradiotinal hook and loop also.

I'm not seeing any of the E2k wool on the AG site. Do they not display them or am I looking in the wrong place.

I'm interested in the traditional hook and loop pads.

AudiOn19s said:I'm not seeing any of the E2k wool on the AG site. Do they not display them or am I looking in the wrong place.

I'm interested in the traditional hook and loop pads.

You have to call them

danponjican

DetailingGurus.com

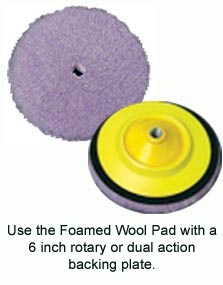

SuperBee364 said:... The Edge line is wonderful, and I also really love LC's purple foamed wool for correction. More so than the yellow edge one, actually. ...

Is this the one you are talking about?

SuperBee364

New member

Yes it is.

Coupe said:Which video?

The link in the original post. I forgot what number, maybe video number 2.

He cleaned that wool pad so damn fast, I just wanna know how he did it.

Jim

SuperBee364

New member

Yup, you can.... AG (and a number of other places), sell this cool pad washer.

It looks pretty cool. There's a video of it being used, but I'm too lazy to look for it now.

Another reason I love wool: dunk the wool in snappy pad cleaner, message a bit, rinse under the tap, and spin it for a couple mins on the rotary at 2400 RPM. Pad is barely damp to the touch and ready to use.

It looks pretty cool. There's a video of it being used, but I'm too lazy to look for it now.

Another reason I love wool: dunk the wool in snappy pad cleaner, message a bit, rinse under the tap, and spin it for a couple mins on the rotary at 2400 RPM. Pad is barely damp to the touch and ready to use.

SuperBee364 said:Another reason I love wool: dunk the wool in snappy pad cleaner, message a bit, rinse under the tap, and spin it for a couple mins on the rotary at 2400 RPM. Pad is barely damp to the touch and ready to use.

Thats basicly what i do after every 2-3 panels.

Except i just use dawn dish soap.

MaximusZTS

New member

danponjican said:I'm fairly new to this level of detailing / paint correction so I figured I would share some of my lessons I learned along the way.

So last night I was finally motivated to finally test out some of my new stuff. I wanted to try to rotary again. Last time I was all over the place with it! I had a really hard time controlling it and was just a frustrating experience overall. So I came across these videos last night on the MOL forums:

Meguiar's Online - How to Introduction to Wetsanding and Rotary Buffing. (Video)

I am glad my video helped you out! Great job!

SuperBee364 said:Yup, you can.... AG (and a number of other places), sell this cool pad washer.

It looks pretty cool. There's a video of it being used, but I'm too lazy to look for it now.

Another reason I love wool: dunk the wool in snappy pad cleaner, message a bit, rinse under the tap, and spin it for a couple mins on the rotary at 2400 RPM. Pad is barely damp to the touch and ready to use.

SuperBee you just made my day...AGAIN!

Man, I thought wool and water didnt mix, I was wondering how I was going to clean the pad off after every couple of panels!

This wool is getting better and better, I hope to have my wool pads by Thursday, Ive got all day Friday to mess with them.

Test door here I come again.

Jim

SuperBee364

New member

Glad I could help, Jim

When you get the wool, you might want to start off with something other than SIP when you're trying out compounding. Even with a wool pad, SIP tends to make the buffer go it's own way a bit more than other, easier-to-use compounds. IP is very easy to use with wool, as is the optimum line. The High Temp line is pretty easy to use, too, but the working time on them isn't very long, especially in this heat. Mixing up a bit of HTEC and OP (about 80% HTEC and 20% OP works well) makes for a farily aggressive compound with a good working time, and it's pretty easy to use with the wool pads.

IP on foamed wool is sooooooooo easy to use. SIP on foamed wool is pretty easy, too, but it's still a bit fussy. IP on foamed is so incredibly easy to control. If you really want to get jiggy with a surface with bad defects, Power Gloss is really easy to control on foamed wool, as well. Huge correction power with that combination, and you'll be able to get a really good look at what hollograms look like.

My favorites so far:

For really heavy correction, PG with purple foamed wool.

For moderate correction, SIP with purple foamed wool. Runner up is IP instead.

For finishing, PO106FF on blue Edge wool, and to really put an incredible gloss on the finish, a second pass of 106ff with the white Edge wool.

A quick single-step process for light/moderate correction: Green Edge wool with SIP.

I've been messing around a bit with the Optimum line lately, too. Must say that I'm impressed with the whole lineup. I really like the High Temp line, too, but the working times are really short in the dry heat we have here.

When you get the wool, you might want to start off with something other than SIP when you're trying out compounding. Even with a wool pad, SIP tends to make the buffer go it's own way a bit more than other, easier-to-use compounds. IP is very easy to use with wool, as is the optimum line. The High Temp line is pretty easy to use, too, but the working time on them isn't very long, especially in this heat. Mixing up a bit of HTEC and OP (about 80% HTEC and 20% OP works well) makes for a farily aggressive compound with a good working time, and it's pretty easy to use with the wool pads.

IP on foamed wool is sooooooooo easy to use. SIP on foamed wool is pretty easy, too, but it's still a bit fussy. IP on foamed is so incredibly easy to control. If you really want to get jiggy with a surface with bad defects, Power Gloss is really easy to control on foamed wool, as well. Huge correction power with that combination, and you'll be able to get a really good look at what hollograms look like.

My favorites so far:

For really heavy correction, PG with purple foamed wool.

For moderate correction, SIP with purple foamed wool. Runner up is IP instead.

For finishing, PO106FF on blue Edge wool, and to really put an incredible gloss on the finish, a second pass of 106ff with the white Edge wool.

A quick single-step process for light/moderate correction: Green Edge wool with SIP.

I've been messing around a bit with the Optimum line lately, too. Must say that I'm impressed with the whole lineup. I really like the High Temp line, too, but the working times are really short in the dry heat we have here.

Hey Superbee,

Thanks for the very informative post. Ive got HTEC and the Optimum line of polishes, so maybe I will mess with those first.

Are you noticing that you need *alot* more 106ff on Edge blue to prime the pad correctly. Seemed like I needed double or triple the amount of usual polish to prime that pad....

Thanks again man!

Jim

Thanks for the very informative post. Ive got HTEC and the Optimum line of polishes, so maybe I will mess with those first.

Are you noticing that you need *alot* more 106ff on Edge blue to prime the pad correctly. Seemed like I needed double or triple the amount of usual polish to prime that pad....

Thanks again man!

Jim

SuperBee364

New member

Jim, it's my pleasure... i hope it helps some... and yes, it does seem to take quite a bit of 106ff to get the blue pad primed. I've been priming them with a solid ring of polish all the way around the pad. Then after the pad is primed, I just use four pea-sized dots on the pad for later applications.

SuperBee364

New member

No worries, man.. I know how that goes.

I've never used a pad conditioner with the wool pads. I just put a solid ring of product around the whole pad, then rub it around on the car panel I'm going to buff, then start out with a slow rpm until it's very evenly spread, then step it up to polishing rpm's. After that initial priming, four dots seem to work very good with 106ff, as well as most polishes except SIP.

I used the pad conditioner spray on foam pads for the initial priming, but don't see a need for it on the wool.

Honestly, I don't think that the spray coniditioners play well with most Menz polishes. Just my experience.

I've never used a pad conditioner with the wool pads. I just put a solid ring of product around the whole pad, then rub it around on the car panel I'm going to buff, then start out with a slow rpm until it's very evenly spread, then step it up to polishing rpm's. After that initial priming, four dots seem to work very good with 106ff, as well as most polishes except SIP.

I used the pad conditioner spray on foam pads for the initial priming, but don't see a need for it on the wool.

Honestly, I don't think that the spray coniditioners play well with most Menz polishes. Just my experience.