tuscarora dave

"Luck" Residue of design

Hello everyone.

For quite some time I've been practicing with stone chip and general paint touch-up repair. Being my own worst critic, I'm rarely happy with my results, though my results have definitely improved over time.

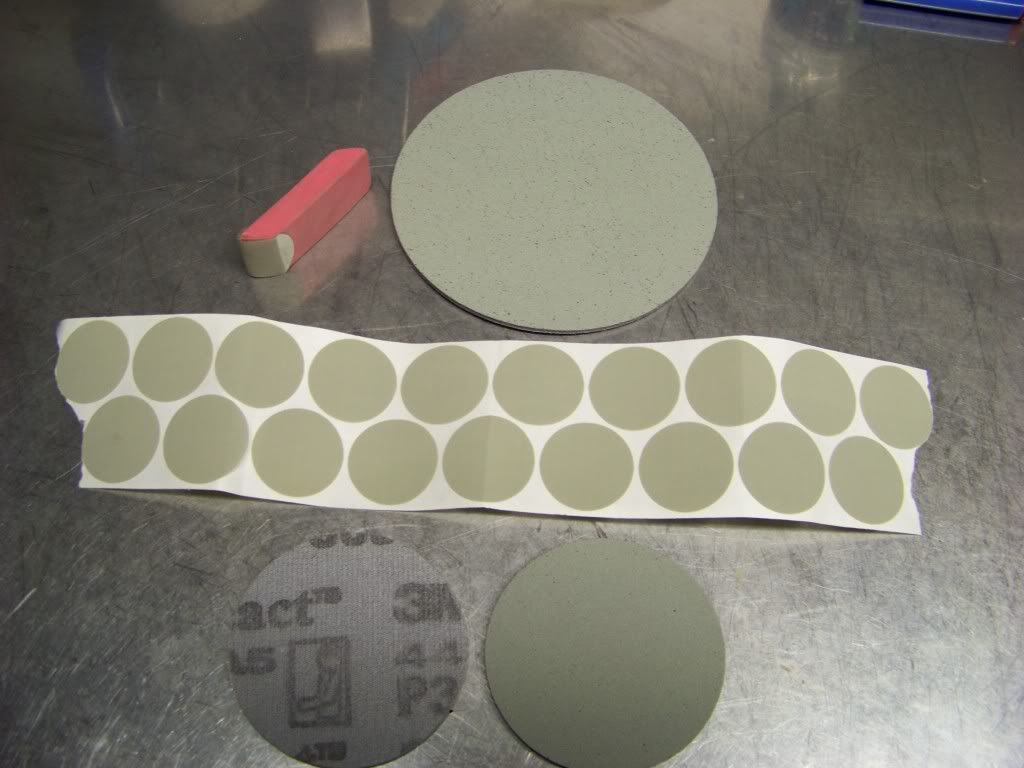

I've used sanding pens, hole punch sized peel and stick sand paper disks stuck to a new pencil eraser, peel and stick paper stuck to my finger tips, 3" sanding disks folded to attempt to accurately sand without getting too far out onto the clear etc. etc.

I've had some really nice results using these sanding techniques, but one thing I've never been able to achieve is the necessary efficiency to provide this as a service. Clients would ask if I provide the service and I typically would just offer to put paint in the chip and be done with it, citing that trying to make an unnoticeable chip repair is a labor of love that takes entirely too long to be economically feasible, so I'd dab a little paint in the chips as carefully as possible and move on, though I always tend to cringe a little upon delivery of the vehicle back to the client.

Lately I've been working on a black 2000 Cadillac ElDorado that's to be flipped come spring time. I've done some touch ups on both bumper scrapes and stone chips with less than desirable results. The client and I began talking about an idea I've had for a while to fashion my own little sanding system that will spin as a rotary but at a much slower rate in order to have a very controlled way to efficiently sand these repairs without the risk of creating so much RPM friction that the paint heats up and gets pulled from the repair during sanding. We agreed to use this Cadillac as a practice vehicle for testing my newly created sanding tool.

Over the last few days I finally moved on the production of my idea and thought I'd share.

Here are a few photos of what I came up with.

Thoughts, questions, comments?

For quite some time I've been practicing with stone chip and general paint touch-up repair. Being my own worst critic, I'm rarely happy with my results, though my results have definitely improved over time.

I've used sanding pens, hole punch sized peel and stick sand paper disks stuck to a new pencil eraser, peel and stick paper stuck to my finger tips, 3" sanding disks folded to attempt to accurately sand without getting too far out onto the clear etc. etc.

I've had some really nice results using these sanding techniques, but one thing I've never been able to achieve is the necessary efficiency to provide this as a service. Clients would ask if I provide the service and I typically would just offer to put paint in the chip and be done with it, citing that trying to make an unnoticeable chip repair is a labor of love that takes entirely too long to be economically feasible, so I'd dab a little paint in the chips as carefully as possible and move on, though I always tend to cringe a little upon delivery of the vehicle back to the client.

Lately I've been working on a black 2000 Cadillac ElDorado that's to be flipped come spring time. I've done some touch ups on both bumper scrapes and stone chips with less than desirable results. The client and I began talking about an idea I've had for a while to fashion my own little sanding system that will spin as a rotary but at a much slower rate in order to have a very controlled way to efficiently sand these repairs without the risk of creating so much RPM friction that the paint heats up and gets pulled from the repair during sanding. We agreed to use this Cadillac as a practice vehicle for testing my newly created sanding tool.

Over the last few days I finally moved on the production of my idea and thought I'd share.

Here are a few photos of what I came up with.

Thoughts, questions, comments?