imported_Dave KG

New member

Not a full detail today, but rather a few hours of one to one (or rather two to one, as Gav had to put up with both me and Bryan!! :lol::lol rotary tuitiontoday for GavB on the forum, on his really rather nice BMW M3 'vert. Lovely colour too, dont see many around in a metallic, amost British Racing green.

rotary tuitiontoday for GavB on the forum, on his really rather nice BMW M3 'vert. Lovely colour too, dont see many around in a metallic, amost British Racing green.

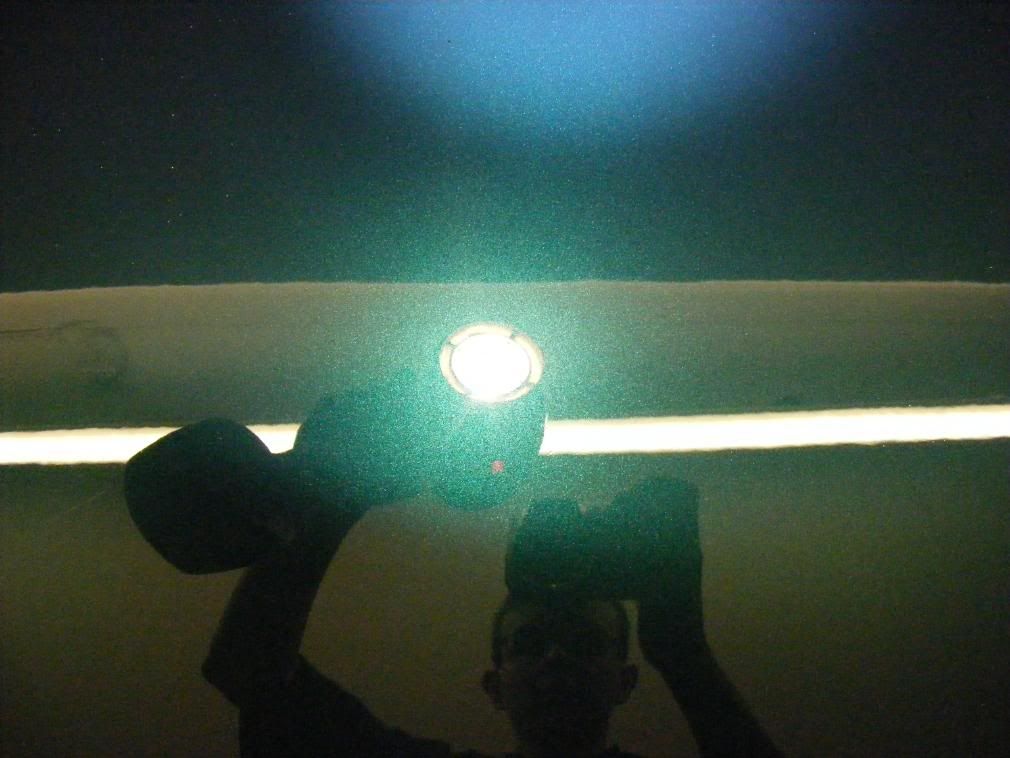

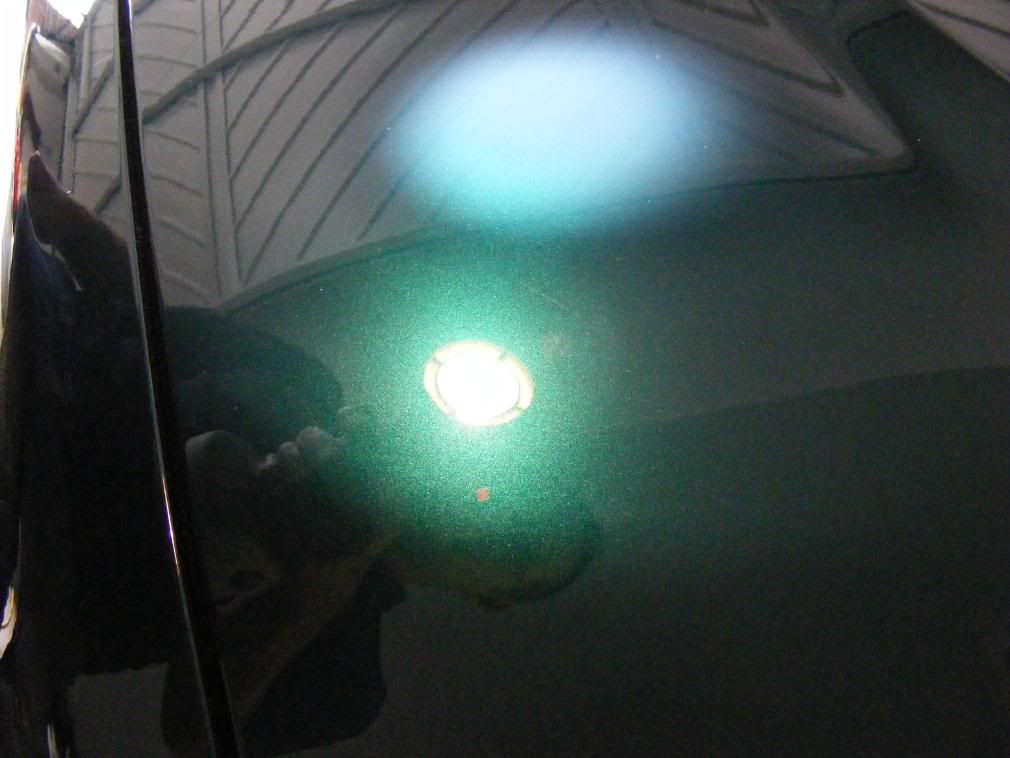

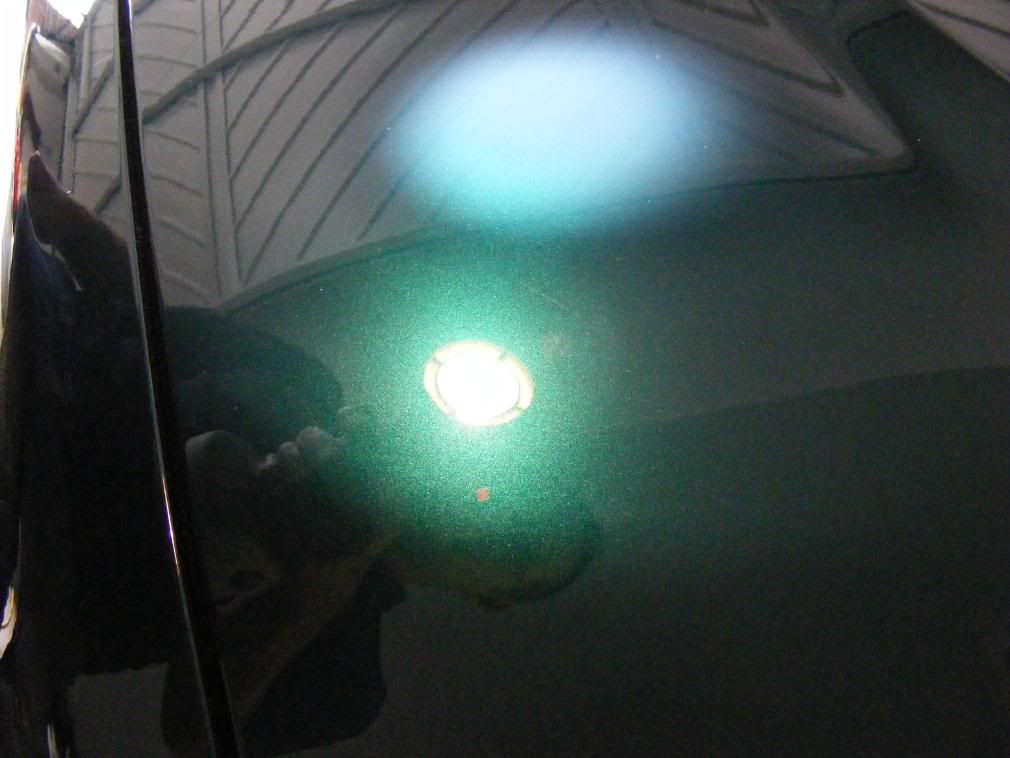

For an 11 year old, the car wasn't badly swirled either...

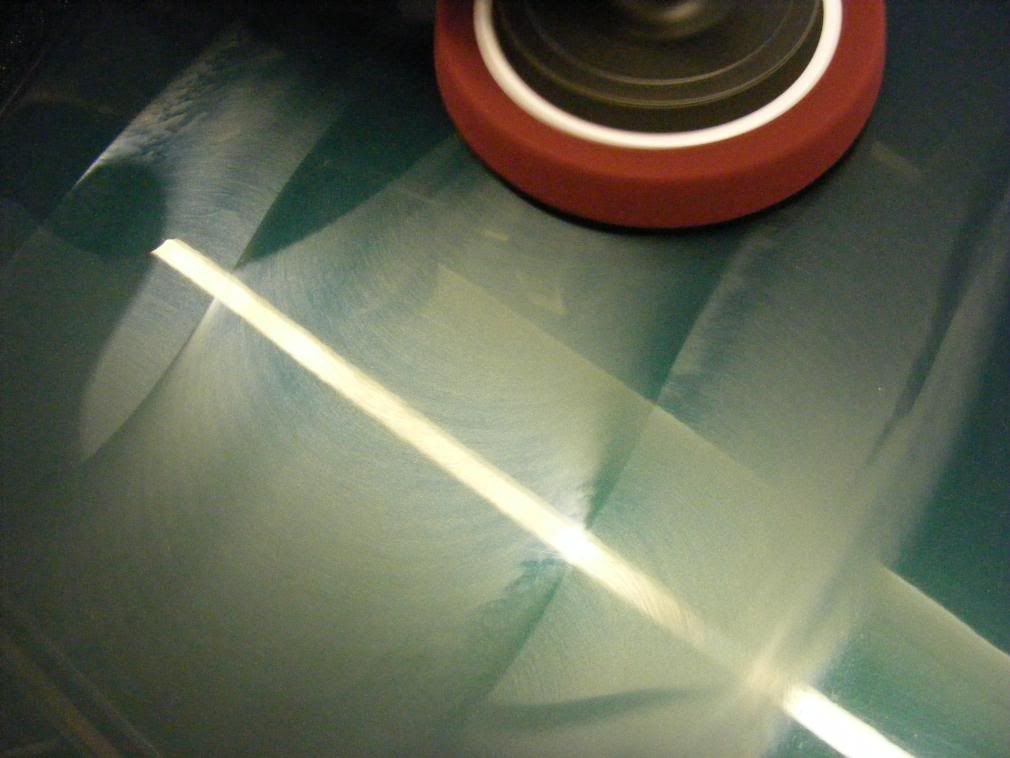

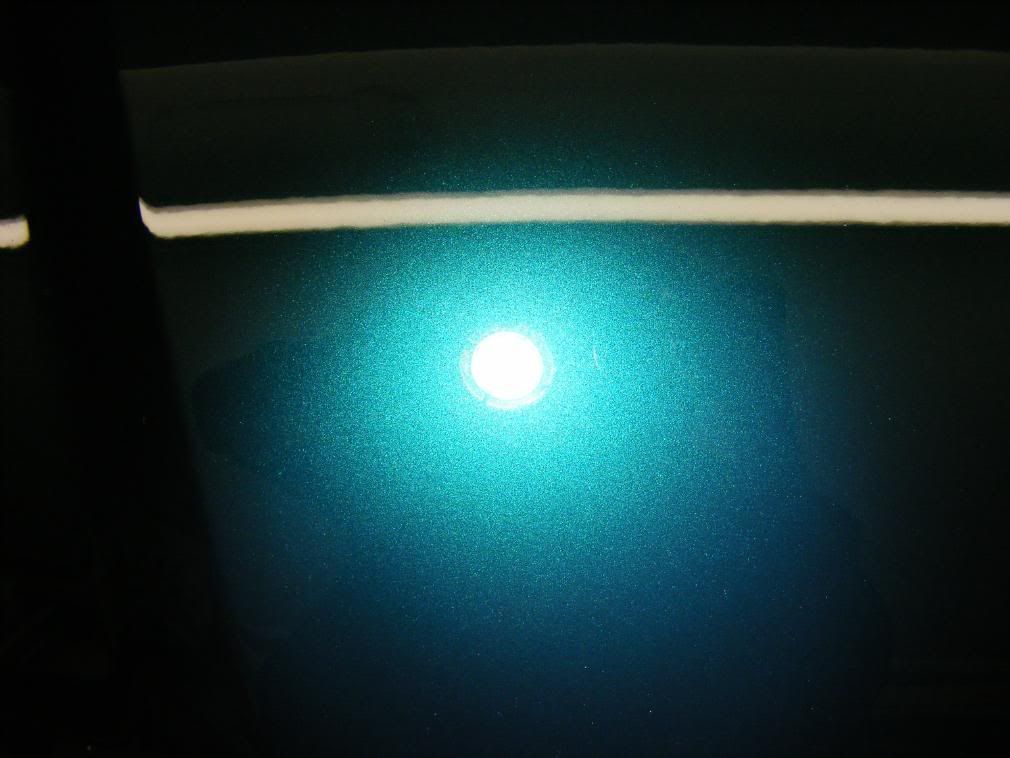

The whole bonnet was like this, with random deeper scratches around as well which would give opportunity to play around with a little heavy compounding techniques and also some wetsanding.

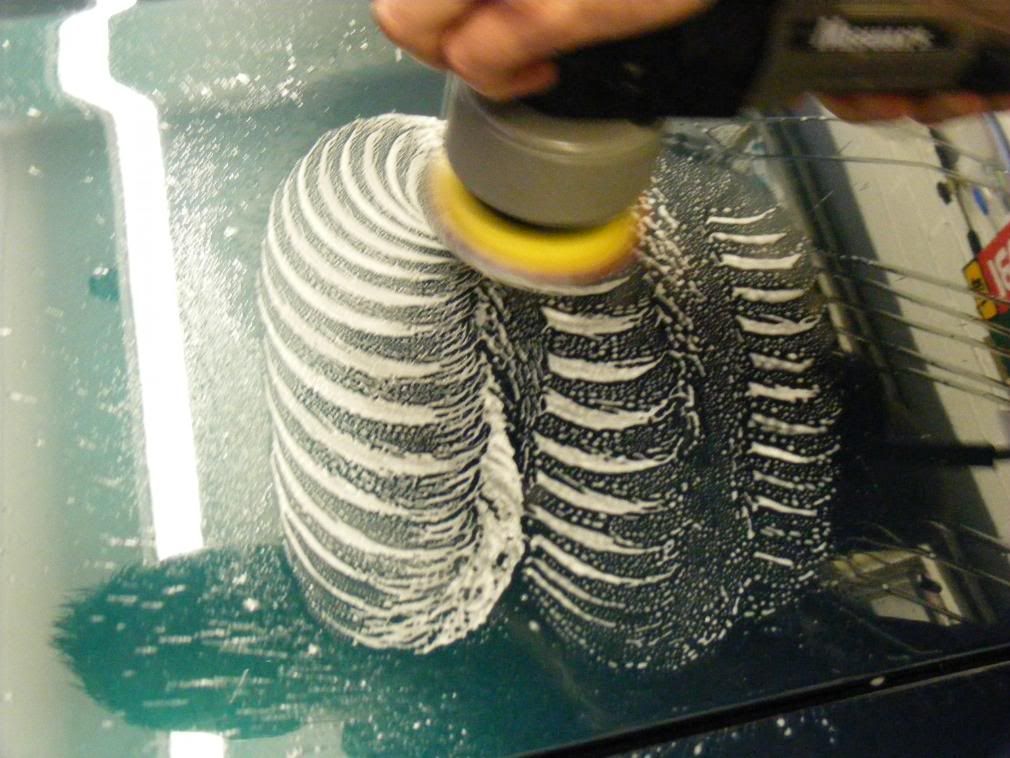

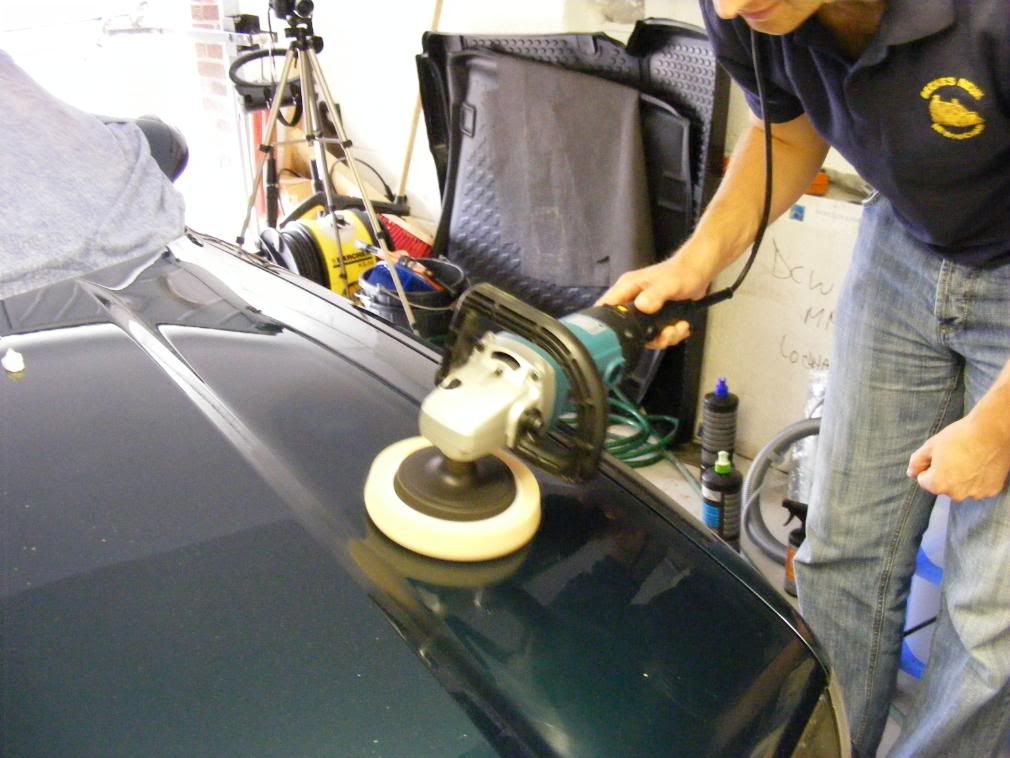

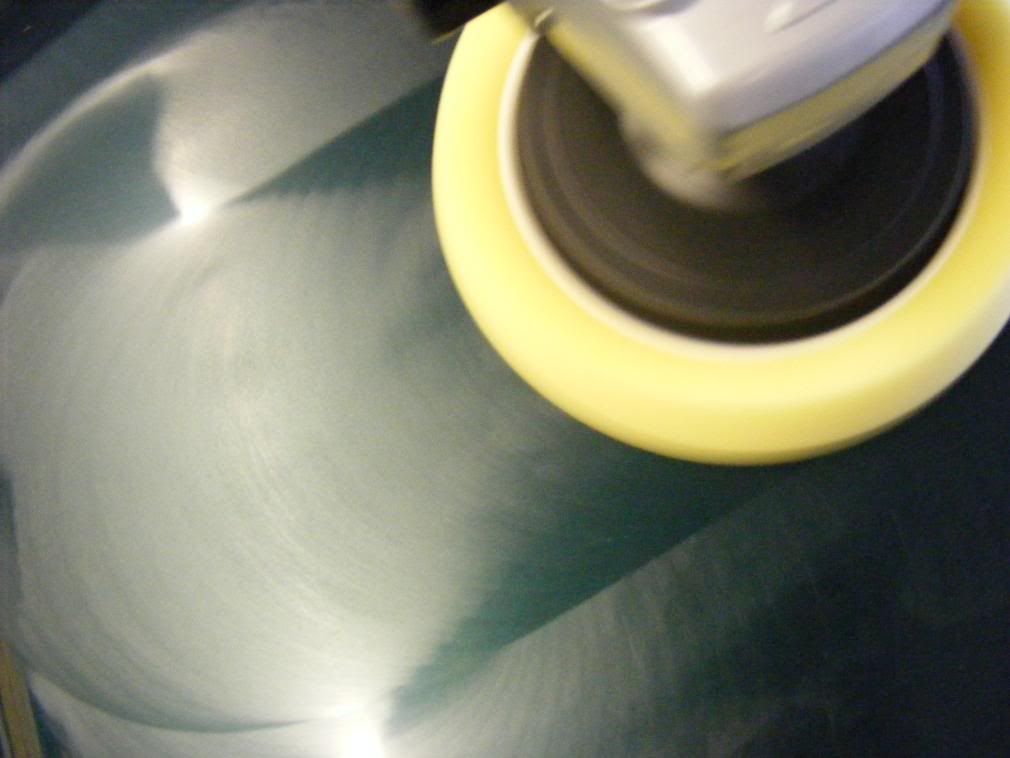

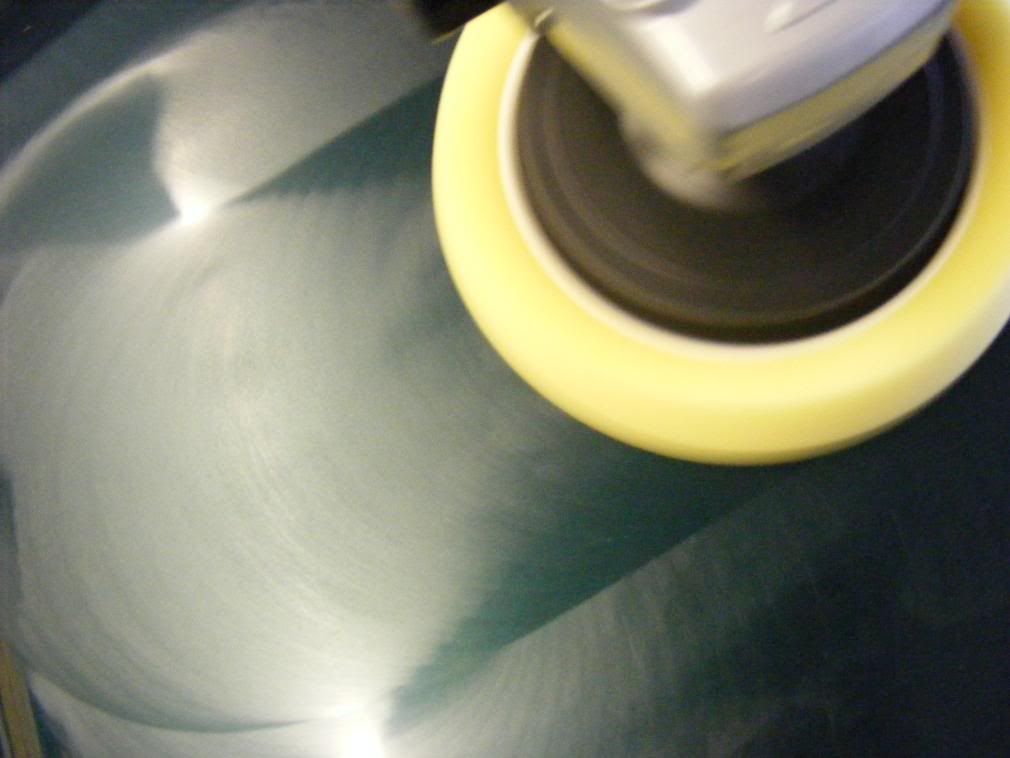

After a little product trialling, we found that for the general swirling, Menzerna Intensive Polish on a Meguiars W8006 polishing pad delivered some very good correction. So after a quick demo from me, using the Zenith Point technique:

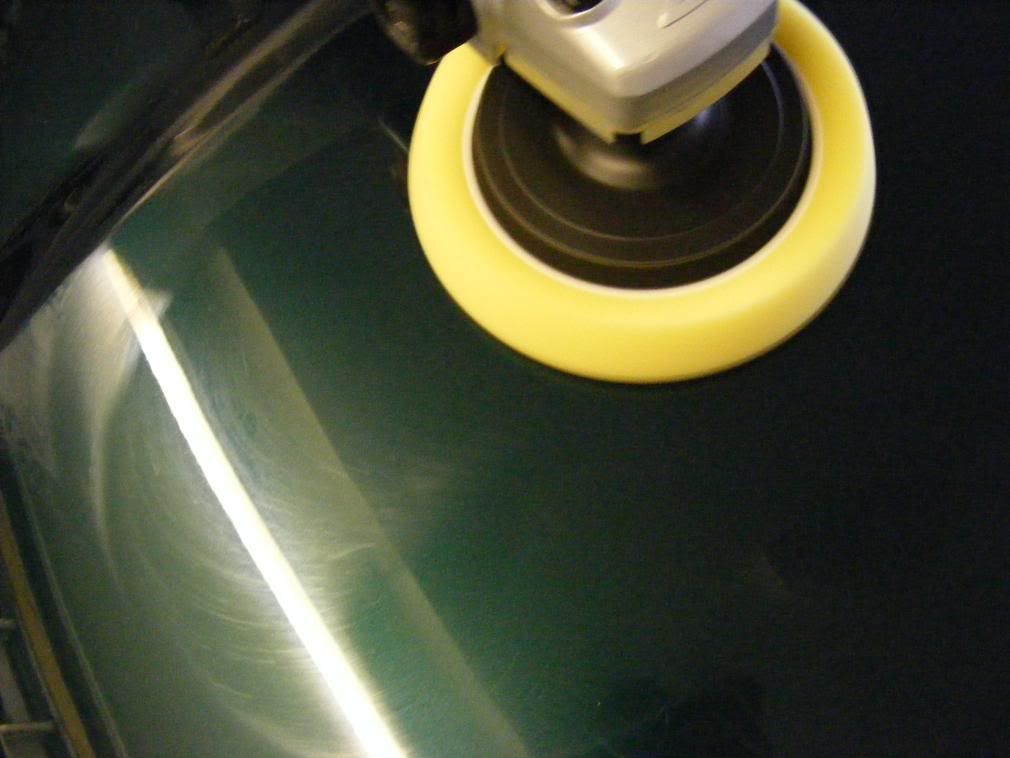

Satisfied with the correction, it was over to Gav who took to the machine like a duck to water in honesty... Not his first time with it, but all the main things were observed:

A couple of pics...

Short video - note the movement speeds, relaxed steady movements, and the pad being flat...

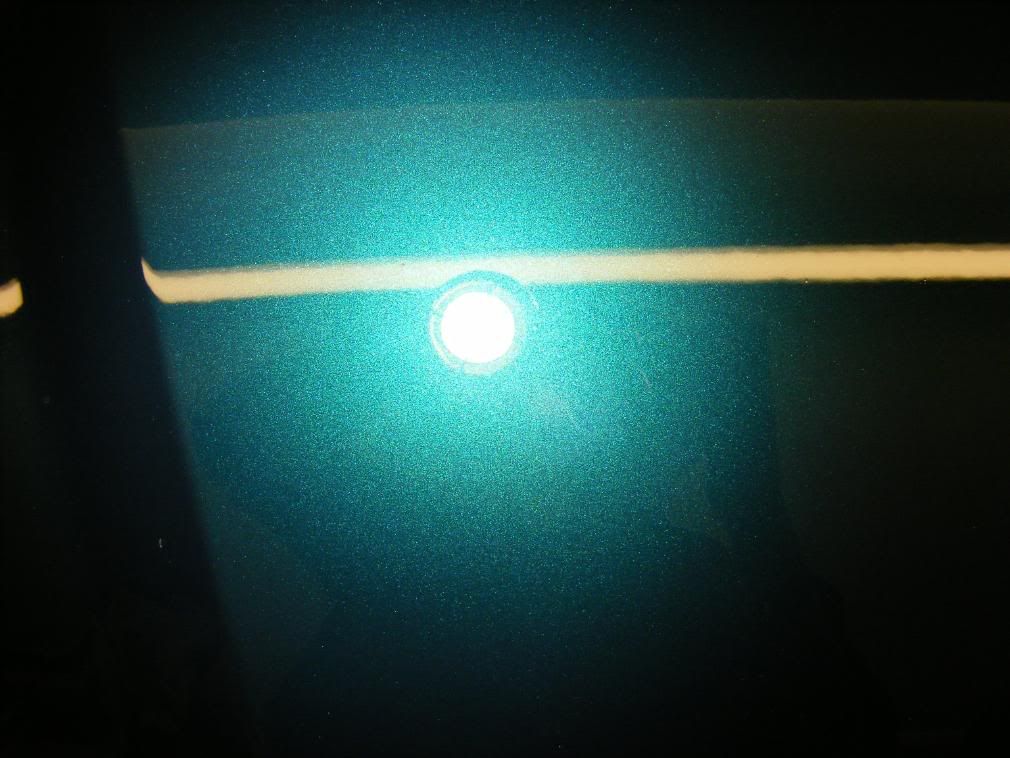

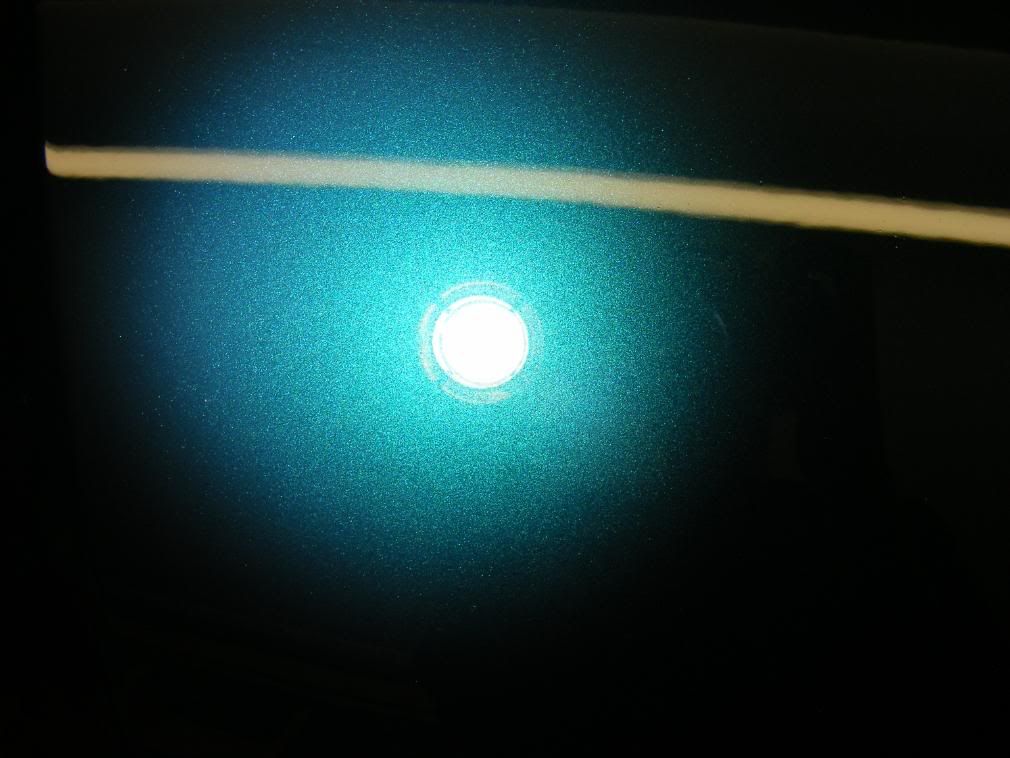

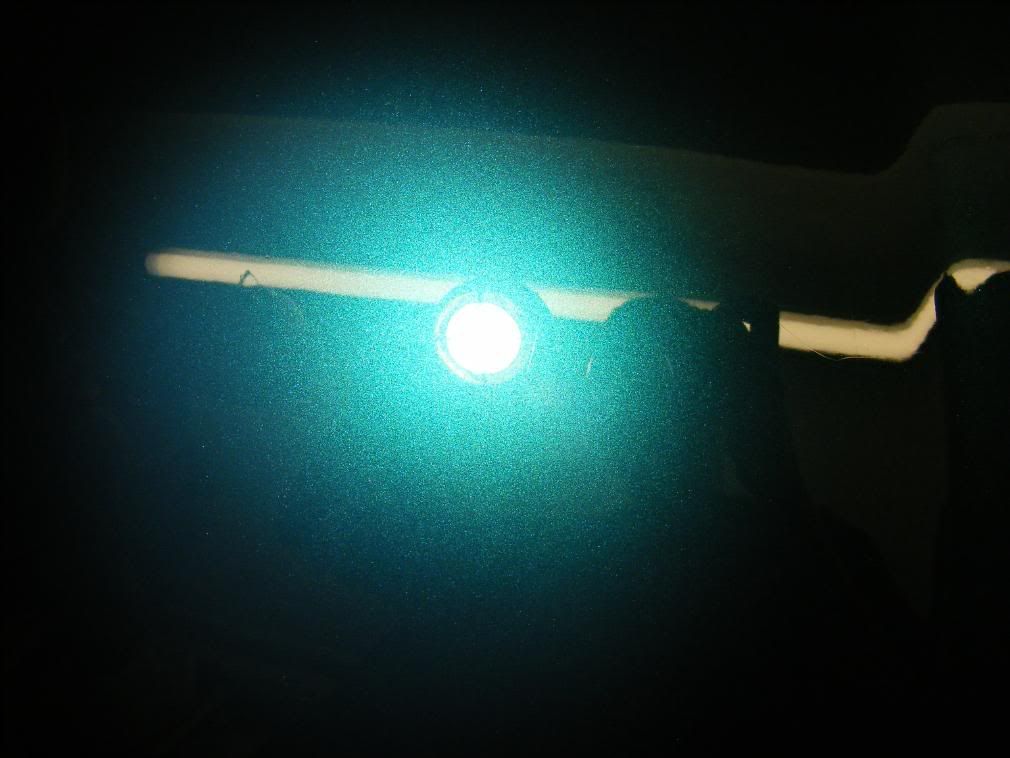

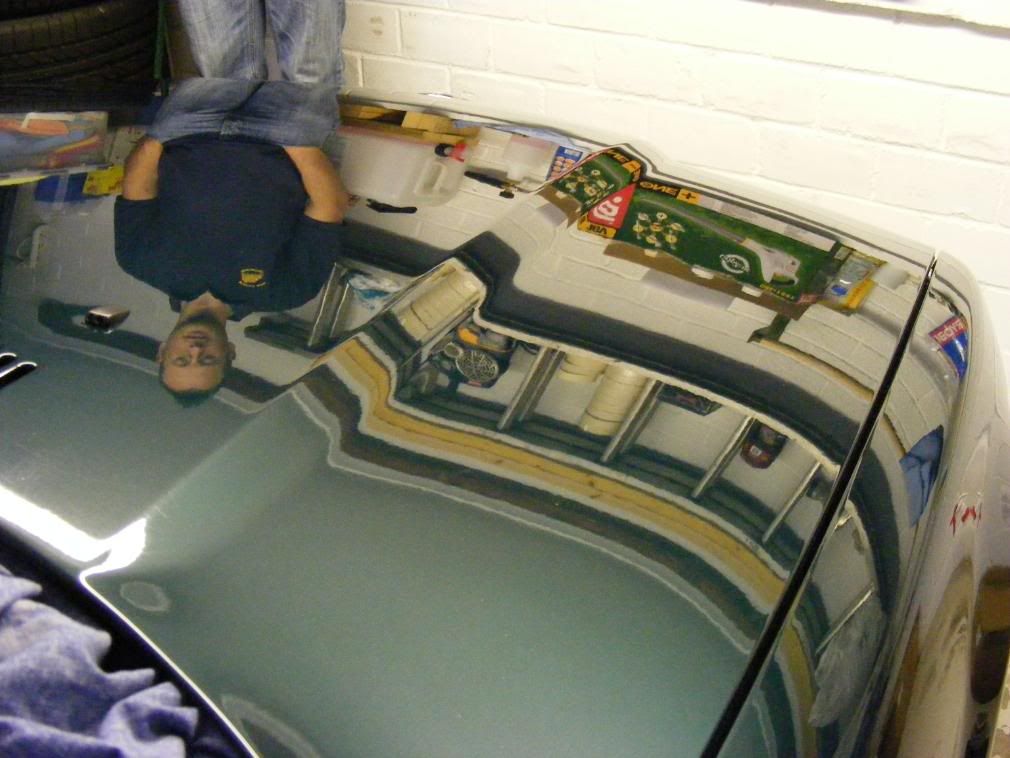

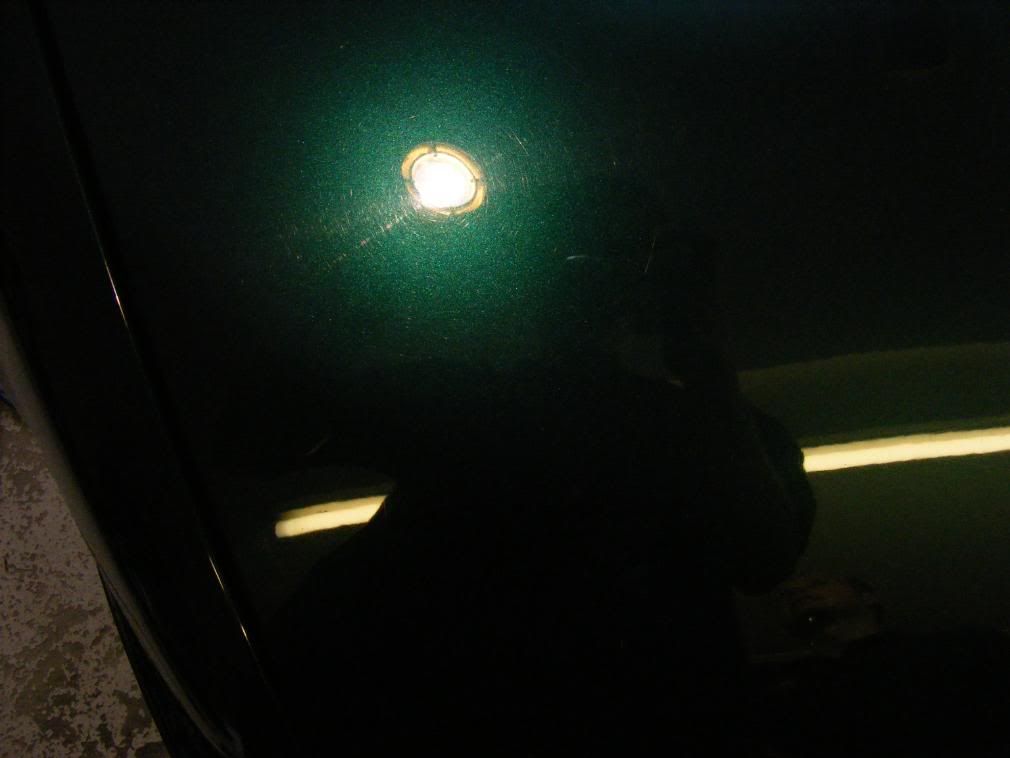

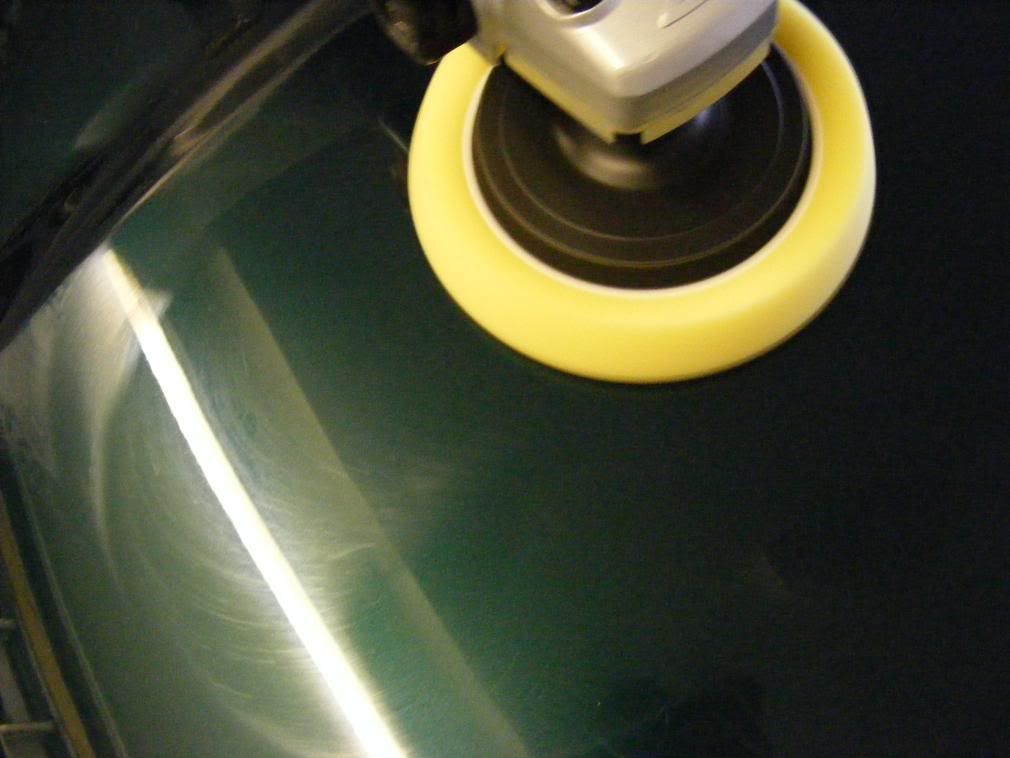

Seemed to work well for Gav, the finished results...

Gav then refined the area with Menzerna Final Finish.

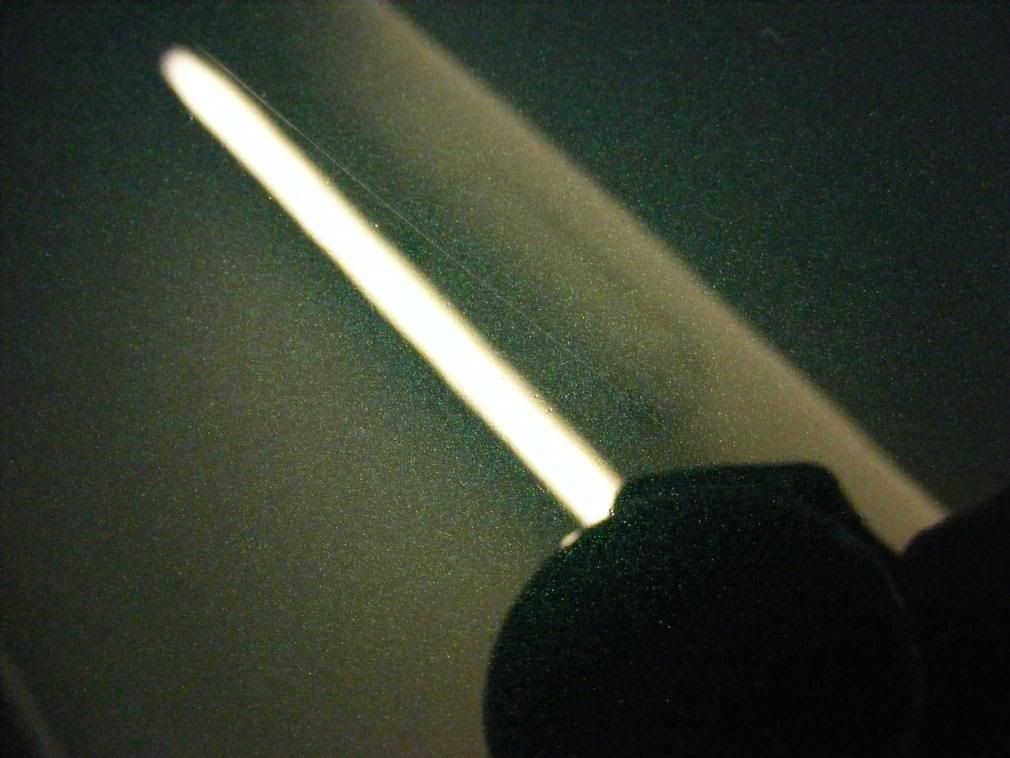

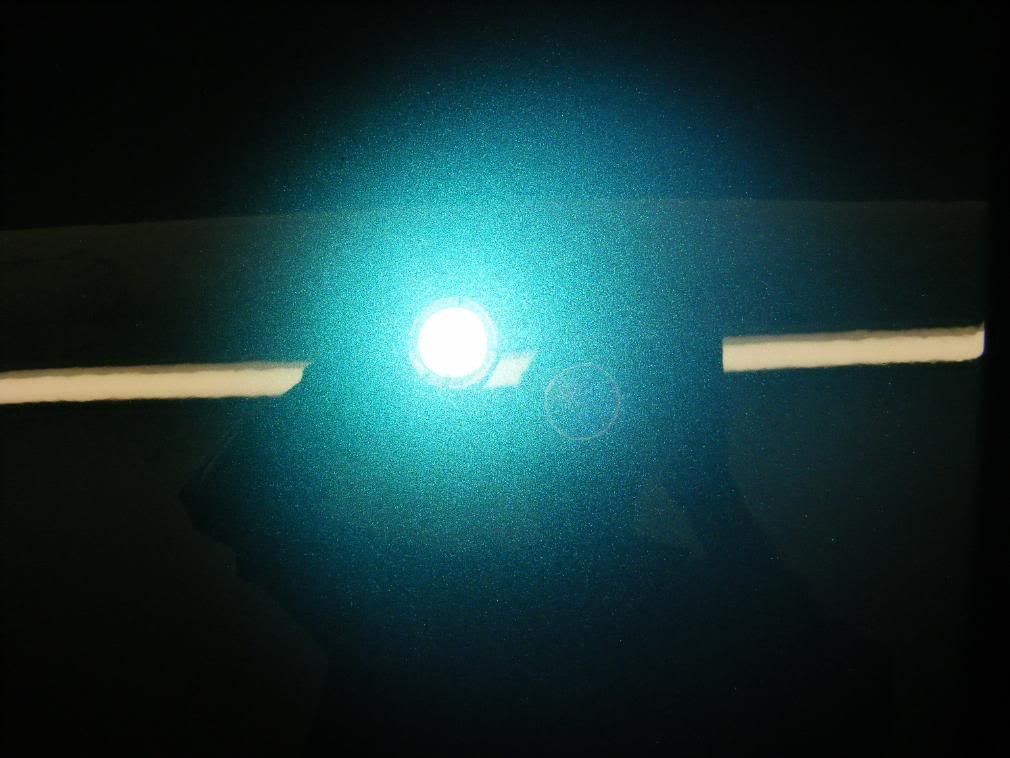

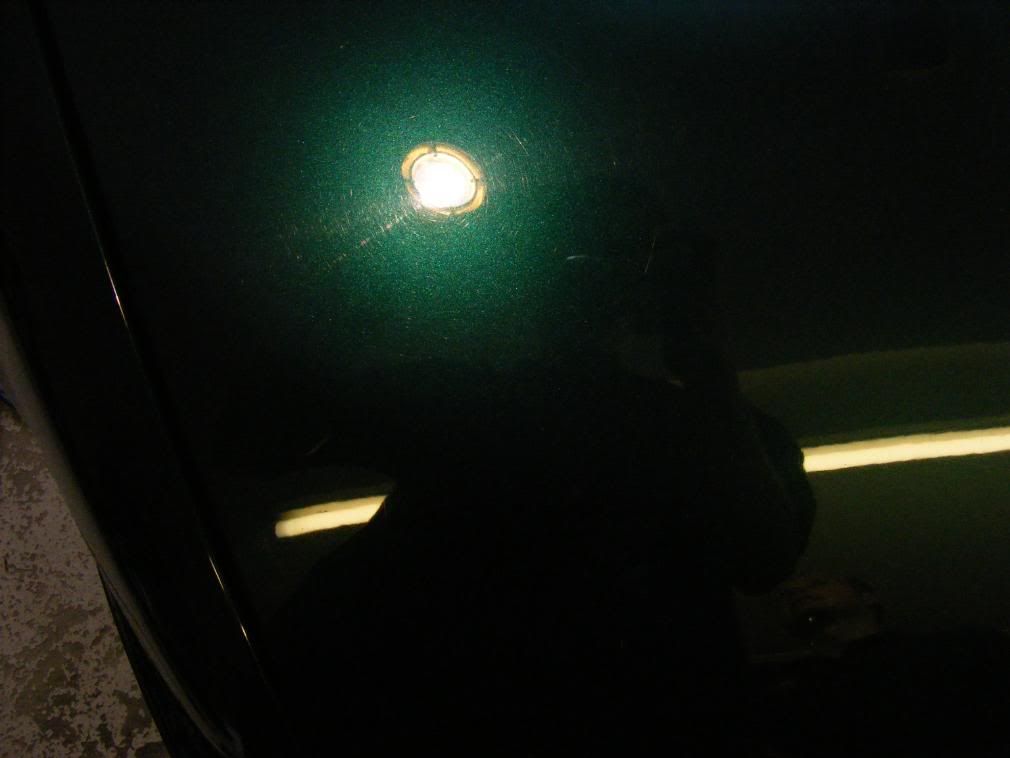

Starting out you see the residue is very cloudy and grey:

Once worked, the residue turns clear to show the polish has broken down and has been properly worked...

Damn good finish, I would say...

For an 11 year old, the car wasn't badly swirled either...

The whole bonnet was like this, with random deeper scratches around as well which would give opportunity to play around with a little heavy compounding techniques and also some wetsanding.

After a little product trialling, we found that for the general swirling, Menzerna Intensive Polish on a Meguiars W8006 polishing pad delivered some very good correction. So after a quick demo from me, using the Zenith Point technique:

- Spread at 600rpm, 1 pass

- Begin to work at 1200rpm, 2 or 3 passes

- Work at 1500rpm until residue clear, around 8 - 10 passes

- Refine at 1200rpm, 2 - 3 passes

Satisfied with the correction, it was over to Gav who took to the machine like a duck to water in honesty... Not his first time with it, but all the main things were observed:

- Pad flat

- Movement steady, no fighting with it

- Relaxed arms to flow with contours

A couple of pics...

Short video - note the movement speeds, relaxed steady movements, and the pad being flat...

Seemed to work well for Gav, the finished results...

Gav then refined the area with Menzerna Final Finish.

Starting out you see the residue is very cloudy and grey:

Once worked, the residue turns clear to show the polish has broken down and has been properly worked...

Damn good finish, I would say...