Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Menzerna PO87c vs. P106FA???

- Thread starter Brewins

- Start date

BIOLINK

Icon Detailing

Can't speak for the two you mentioned, but I love PO85RD on soft paint.

Setec Astronomy

Well-known member

The PO87MC (FPII) doesn't have the abrasives for Ceramiclear paints. Some people think it finishes out better on soft paints, but that doesn't seem to be a widespread opinion. Why doesn't it get much attention? It's older technology, more paint is hard than soft, people don't want to have so many finishing polishes, PO85RD works better?? One or more of those reasons.

Concours.John

Auto Detail & Restoration

106fa and 87mc finish out better with a rotary and IMO more designed for that use. I don't really use 87mc that much at all. 106fa does work with the ceramic clears. Po85rd seems to work great with a rotary or PC.

There is IMO more of a learning

curve with Menzerna than other polishes.

I have found what works for someone else doesn't always seem

to work for the other guy.

There is IMO more of a learning

curve with Menzerna than other polishes.

I have found what works for someone else doesn't always seem

to work for the other guy.

I thought it was the other way around, 106fa works good with a DA, while 85rd works better with a rotary?106fa and 87mc finish out better with a rotary and IMO more designed for that use. I don't really use 87mc that much at all. 106fa does work with the ceramic clears. Po85rd seems to work great with a rotary or PC.

There is IMO more of a learning

curve with Menzerna than other polishes.

I have found what works for someone else doesn't always seem

to work for the other guy.

Concours.John

Auto Detail & Restoration

I thought it was the other way around, 106fa works good with a DA, while 85rd works better with a rotary?

I've only used it on the rotary(106fa) before. When I tried with the PC it to me didn't finish down the same. If on a PC I always use 85rd on speed 6 and constant pad rotation/med to light pressure. Up until the past couple years I only used a PC for LSP's this could be part of my problem.

Upon asking around (paint/product suppliers) I have received mixed answers some say Menzerna sould only be used with a rotary. Others say certain ones will work but rotation and speed are critical. A Flex was suggested above a PC by most.

I personally would like to hear from someone who uses Menzerna only with a PC it could probably answer this question more. I was only speaking from my personal experience with the product. My technique may be different which has created the results spoken of.

You do have a valid question. Everyones technique varies in some way. Results can vary due to this.

Garry Dean

Garry Dean Quality!

I've only used it on the rotary(106fa) before. When I tried with the PC it to me didn't finish down the same. If on a PC I always use 85rd on speed 6 and constant pad rotation/med to light pressure. Up until the past couple years I only used a PC for LSP's this could be part of my problem.

Upon asking around (paint/product suppliers) I have received mixed answers some say Menzerna sould only be used with a rotary. Others say certain ones will work but rotation and speed are critical. A Flex was suggested above a PC by most.

I personally would like to hear from someone who uses Menzerna onlky with a PC it could probably answer this question more. I was only speaking from my personal experience with the product. My technique may be different which has created the results spoken of.

You do have a valid question. Everyones technique varies in some way. Results can vary due to this.

John has got the answers pretty well nailed. The only menz polish I use with a da is po203 (power finish). Menzerna polishes are designed to work via rotary. I have been told that they don't even test their products with a da. Very similar to 3m.

I've always thought this as well. Thanks guys.Menzerna polishes are designed to work via rotary.

Prima polishes use diminishing abrasives too, but they're optimized for DA use according to Nick@Prima. He said his products don't need heat to breakdown, but Menzerna polishes do. I think I'm gonna try Prima Finish.

Todd@RUPES

Just a regular guy

I hope I can help clear up some confusion regarding Menzerna polishes.

PO87mc is an older version of Menzerna's final polishes, it has been around a long time and does a fairly good job of polishing all paints.

PO106ff (and then fa) is (out of the one's mentioned) Menzerna's newest polish, and out of the one's mentioned it features the finest abrasives. This doesn't necessarily mean that it finishes the best (most will agree that PO85rd will finish better on most paint systems).

PO85rd is older than 106ff/fa, but is generally creates the best finish.

As far as the rotary/da is concerned, I have heard the same misinformation as well. The fact is that most OEM manufacturers use high speed pneumatic DA's, some use rotary polishers, and some use regular electric DA's. It really depends on the plant. As far as a polish being specifically designed for one machine or another, I have had the pleaseure of working with enough pre-beta formulations from various manufacturers and this has never been a concern, expect when I was pre-beta testing the Meguiar's DA microfiber system. The difference is (with the Meguiar's DA system) the pads are DA specific, and the polishes were designed to attach completely and evenly to the microfiber. Whether you are using a DA or a rotary you are still moving abrasives across the paint that are attached to a pad. Perhaps drier polishes may lend more cutting power when used with a DA, but that is really as deep as it goes.

Lastly, the idea that any abrasive needs 'heat' (as an increase in temperature) to break down is completely not true. Menzerna uses aluminum oxide clusters (which are fairly common). If you take these aluminum oxide clusters and put them in a stove or outside in the sun they will not magically break down. What breaks down abrasives is friction, and because aluminum oxide is clustered, it will break down when used with a DA, a rotary, or hand.

PO87mc is an older version of Menzerna's final polishes, it has been around a long time and does a fairly good job of polishing all paints.

PO106ff (and then fa) is (out of the one's mentioned) Menzerna's newest polish, and out of the one's mentioned it features the finest abrasives. This doesn't necessarily mean that it finishes the best (most will agree that PO85rd will finish better on most paint systems).

PO85rd is older than 106ff/fa, but is generally creates the best finish.

As far as the rotary/da is concerned, I have heard the same misinformation as well. The fact is that most OEM manufacturers use high speed pneumatic DA's, some use rotary polishers, and some use regular electric DA's. It really depends on the plant. As far as a polish being specifically designed for one machine or another, I have had the pleaseure of working with enough pre-beta formulations from various manufacturers and this has never been a concern, expect when I was pre-beta testing the Meguiar's DA microfiber system. The difference is (with the Meguiar's DA system) the pads are DA specific, and the polishes were designed to attach completely and evenly to the microfiber. Whether you are using a DA or a rotary you are still moving abrasives across the paint that are attached to a pad. Perhaps drier polishes may lend more cutting power when used with a DA, but that is really as deep as it goes.

Lastly, the idea that any abrasive needs 'heat' (as an increase in temperature) to break down is completely not true. Menzerna uses aluminum oxide clusters (which are fairly common). If you take these aluminum oxide clusters and put them in a stove or outside in the sun they will not magically break down. What breaks down abrasives is friction, and because aluminum oxide is clustered, it will break down when used with a DA, a rotary, or hand.

Old Pirate

AMG Classic Car Detailing

Well Todd got here before I can, he's right on this one.

BIOLINK

Icon Detailing

Well I was gonna say I have used 87 and 85 with my PC beautifully. Todd said it better though.

My new fave combo is the PO85RD via PC with the Crimson Hydro pads. That was a recommendation from Angelo.

Thanks Angelo.

My new fave combo is the PO85RD via PC with the Crimson Hydro pads. That was a recommendation from Angelo.

Thanks Angelo.

Old Pirate

AMG Classic Car Detailing

It's the bomb!

Garry Dean

Garry Dean Quality!

I hope I can help clear up some confusion regarding Menzerna polishes.

PO87mc is an older version of Menzerna's final polishes, it has been around a long time and does a fairly good job of polishing all paints.

PO106ff (and then fa) is (out of the one's mentioned) Menzerna's newest polish, and out of the one's mentioned it features the finest abrasives. This doesn't necessarily mean that it finishes the best (most will agree that PO85rd will finish better on most paint systems).

PO85rd is older than 106ff/fa, but is generally creates the best finish.

As far as the rotary/da is concerned, I have heard the same misinformation as well. The fact is that most OEM manufacturers use high speed pneumatic DA's, some use rotary polishers, and some use regular electric DA's. It really depends on the plant. As far as a polish being specifically designed for one machine or another, I have had the pleaseure of working with enough pre-beta formulations from various manufacturers and this has never been a concern, expect when I was pre-beta testing the Meguiar's DA microfiber system. The difference is (with the Meguiar's DA system) the pads are DA specific, and the polishes were designed to attach completely and evenly to the microfiber. Whether you are using a DA or a rotary you are still moving abrasives across the paint that are attached to a pad. Perhaps drier polishes may lend more cutting power when used with a DA, but that is really as deep as it goes.

Lastly, the idea that any abrasive needs 'heat' (as an increase in temperature) to break down is completely not true. Menzerna uses aluminum oxide clusters (which are fairly common). If you take these aluminum oxide clusters and put them in a stove or outside in the sun they will not magically break down. What breaks down abrasives is friction, and because aluminum oxide is clustered, it will break down when used with a DA, a rotary, or hand.

So, are you saying that the menzerna polishes are designed for the abrasives to break down the same no matter what machine or hand application you choose? Seems like you are saying that the end result should be exactly the same no matter how the polishes are broken down. Is that what you're saying?

I don't use menzerna regularly besides po203. Just trying to understand what you're saying.

C. Charles Hahn

CCH Auto Appearance, LLC

So, are you saying that the menzerna polishes are designed for the abrasives to break down the same no matter what machine or hand application you choose? Seems like you are saying that the end result should be exactly the same no matter how the polishes are broken down. Is that what you're saying?

I don't use menzerna regularly besides po203. Just trying to understand what you're saying.

I would imagine the abrasives would still "break down" regardless of how friction is applied to them, but may break down in slightly different ways depending on the nature of that friction (technique dependent)....

For me, I only started using Menzerna polishes within the past year or so but having "grown up" during the Meguiar's M8x-series era and being used to diminishing abrasives in that context, I found that the same principles largely apply in terms of working them down. So for anyone who may be more familiar with the performance and properties of that line, it may give you some additional insight into working with Menzerna products as well -- just putting that out there.

Todd@RUPES

Just a regular guy

So, are you saying that the menzerna polishes are designed for the abrasives to break down the same no matter what machine or hand application you choose? Seems like you are saying that the end result should be exactly the same no matter how the polishes are broken down. Is that what you're saying?

I don't use menzerna regularly besides po203. Just trying to understand what you're saying.

Let me see if can clarify what I was saying, if I understand that your saying that you didn't understand what I saying, you know what I'm saying?

So, are you saying that the menzerna polishes are designed for the abrasives to break down the same no matter what machine or hand application you choose?

That wasn't exactly my point. You really can't design any diminishing abrasive to break down exactly the same irregardless of application method because it is friction (not heat) that causes them to break apart. Since each application method (even similar application machines with different speeds, pads, paint hardness, etc) impart different amounts of friction, the abrasives will break down differently.

My point was that aluminum oxide abrasives used in Menzerna or other polishes are going to break down from friction, regardless of how the friction is applied. This isn't to say that some people may or may not get better results with particular application methods.

Also, Menzerna is/was primarily an OEM abrasive manufacturer. The products are/where optimized for the different needs at the OEM level, where pneumatic DA's are used quite frequently. While I am not 100% sure what Menzerna's internal testing policies/procedures I know a gentleman in Germany who does external testing for Menzerna as he testes the products on various machines including DA polishers.

Seems like you are saying that the end result should be exactly the same no matter how the polishes are broken down. Is that what you're saying?

Again I am sorry for the confusion. The results will not be exactly the same as there are many factors that contribute to the overall result, such as application method, pad selection, speed, paint hardness, chemical contamination, and environmental factors. However, provided enough friction is applied (regardless of how it is applied) the abrasives will fracture apart.

Todd@RUPES

Just a regular guy

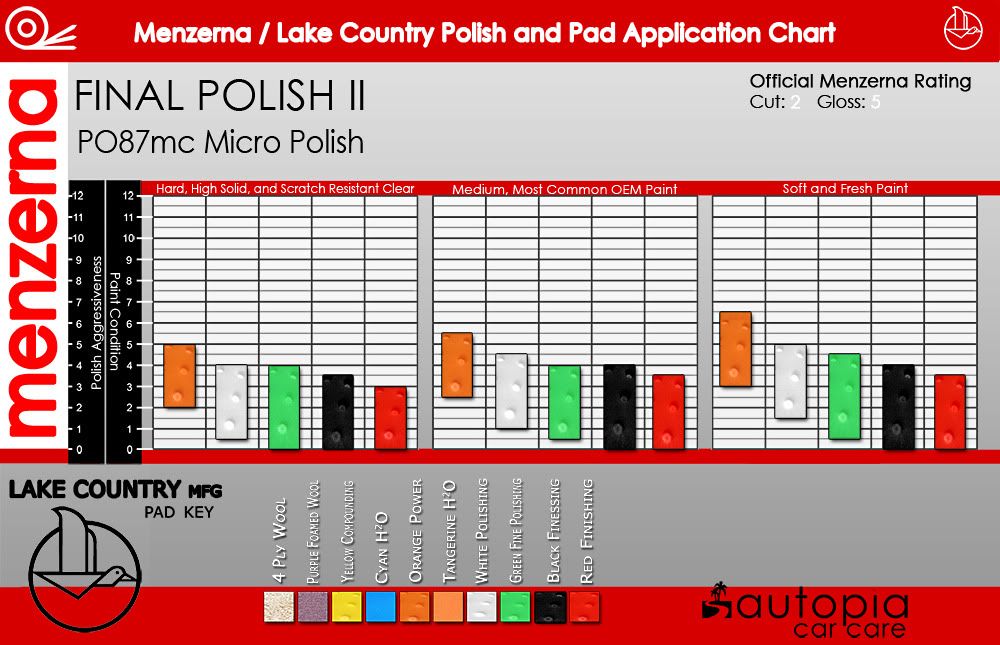

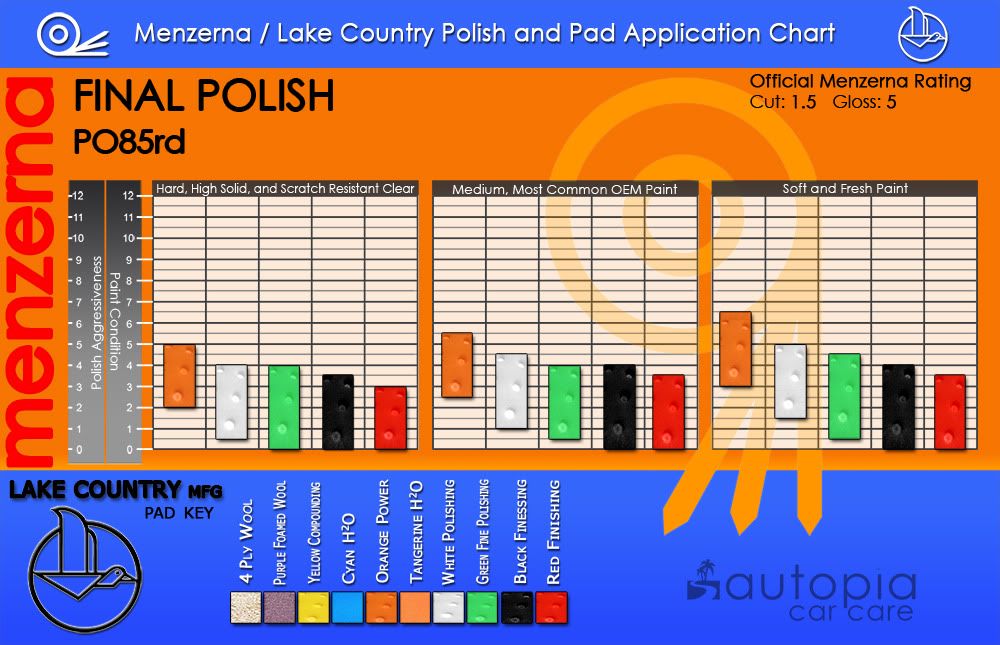

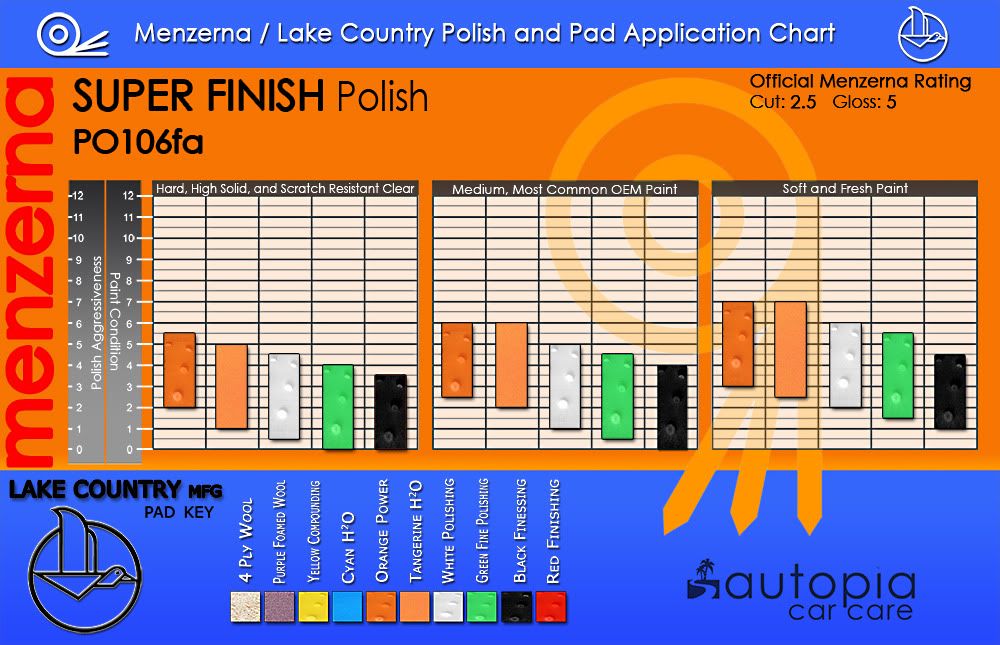

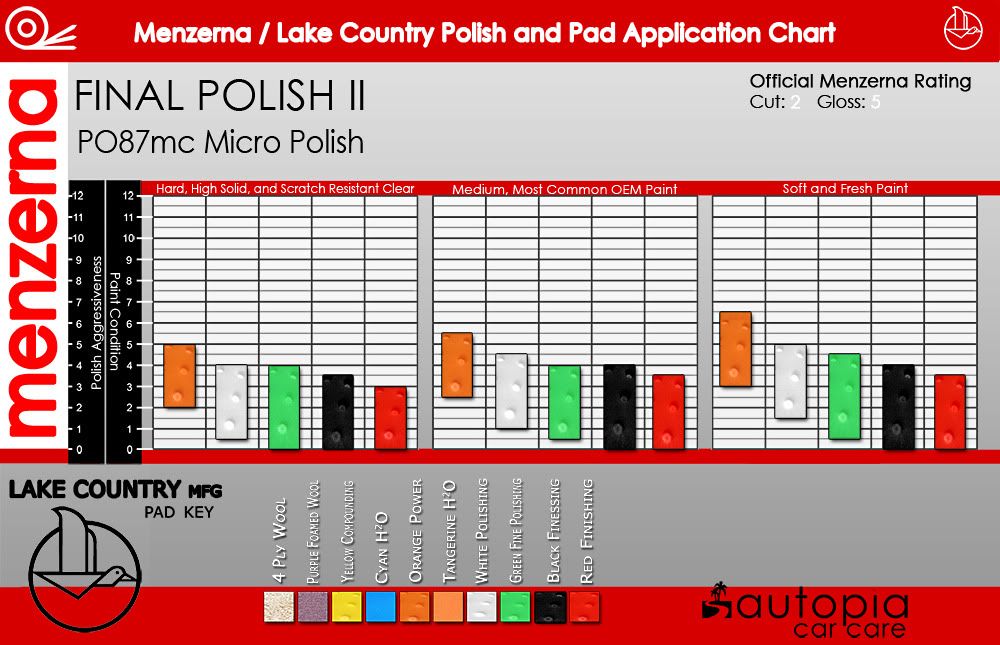

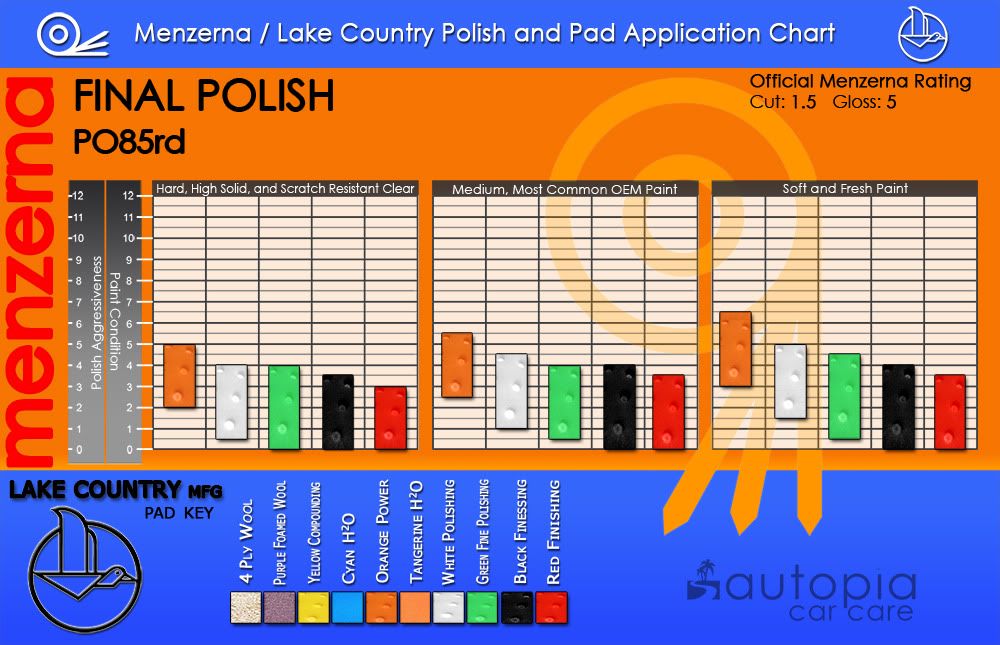

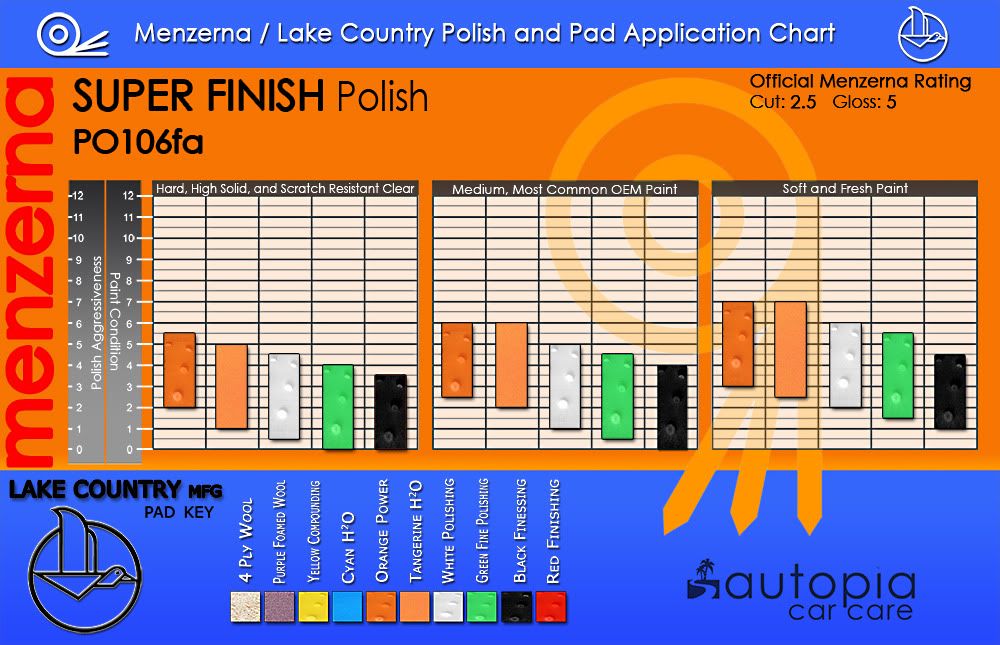

Here are some charts that I built to show the typical polishing range (based on Menzerna's numbers as well as my experience in using Menzerna on over 300 cars) that show the typical (for reference only!) reaction on paint systems.

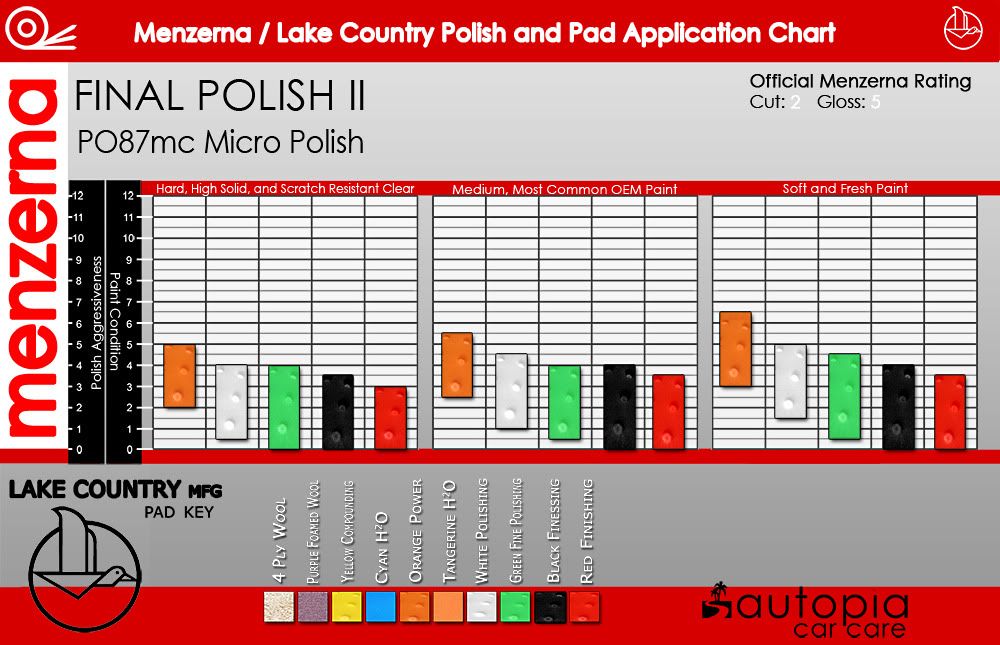

PO87mc aka Final polish II.

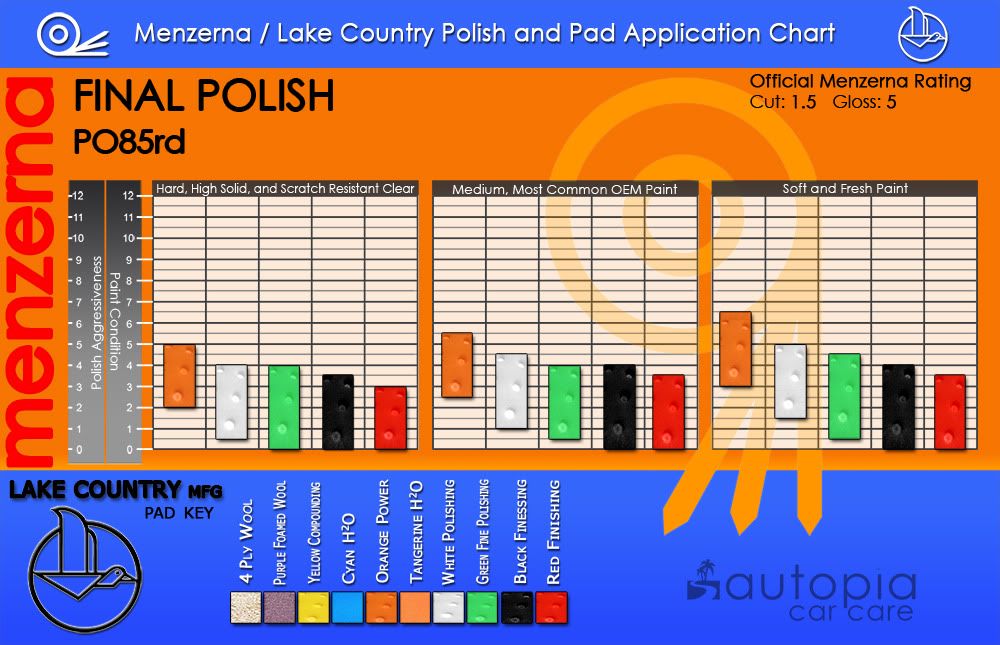

PO85rd

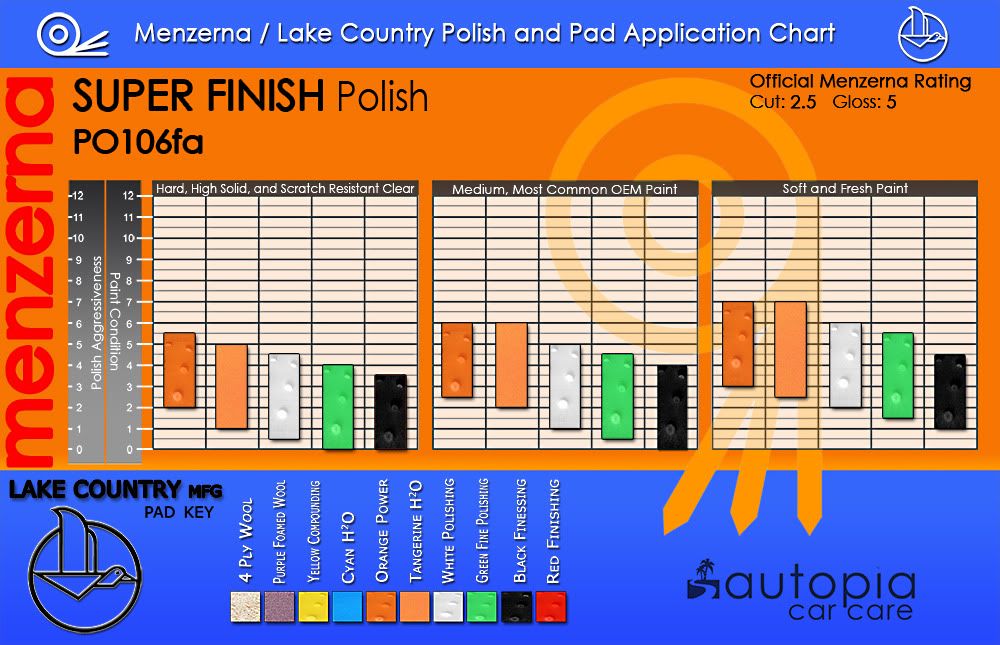

PO106ff/fa

PO87mc aka Final polish II.

PO85rd

PO106ff/fa

Concours.John

Auto Detail & Restoration

Here are some charts that I built to show the typical polishing range (based on Menzerna's numbers as well as my experience in using Menzerna on over 300 cars) that show the typical (for reference only!) reaction on paint systems.

PO87mc aka Final polish II.

PO85rd

PO106ff/fa

I had a question. Understanding that these are for reference. How do the H20 compare to Ccs on the chart? My experience is with Ccs, Shlagel (blue,green), and 3M.

Forgive my ignorance I wasn't sure if those were the only 2 pads offered.

Todd@RUPES

Just a regular guy

The H20 pad's and CCS pads are both referenced on the chart. However (because of space and typical usage) I had to pick the pads that are most likely to be used on the chart with the polish. For example using a foam cutting wool with PO85rd wouldn't make much sense, or using a black finishing foam with Power Gloss compound wouldn't make much sense.

In general the Cyan H20 pad cuts near the same as the Lake Country yellow foam, but finishes a little better.

The Tangerine H20 pad cuts near the same as the Lake Country orange foam but finishes slightly better.

The Crimson H20 pad cuts about the same as a Lake Country white pad and finishes on par with the black foam.

Does this help or did I miss the question?

In general the Cyan H20 pad cuts near the same as the Lake Country yellow foam, but finishes a little better.

The Tangerine H20 pad cuts near the same as the Lake Country orange foam but finishes slightly better.

The Crimson H20 pad cuts about the same as a Lake Country white pad and finishes on par with the black foam.

Does this help or did I miss the question?

Concours.John

Auto Detail & Restoration

I had a question. Understanding that these are for reference. How do the H20 compare to Ccs on the chart? My experience is with Ccs, Shlagel (blue,green), and 3M.

Forgive my ignorance I wasn't sure if those were the only 2 pads offered.

It makes total sense.

I wasn't wanting to misdirect the thread. My thoughts were directly applied to how these pad differences react to Menzerna.

I may have created a bigger learning curve during my transition to the CCS. I noticed a break down and pressure difference from always using flat foam vs. CCS. Ie: Less surface for friction to break down the polish faster with CCS.

Thank you

Bill D

Hooked For Life

Fantastic chart! Cuts through the confusion. I'm pressing the print button! :bigups