imported_Dave KG

New member

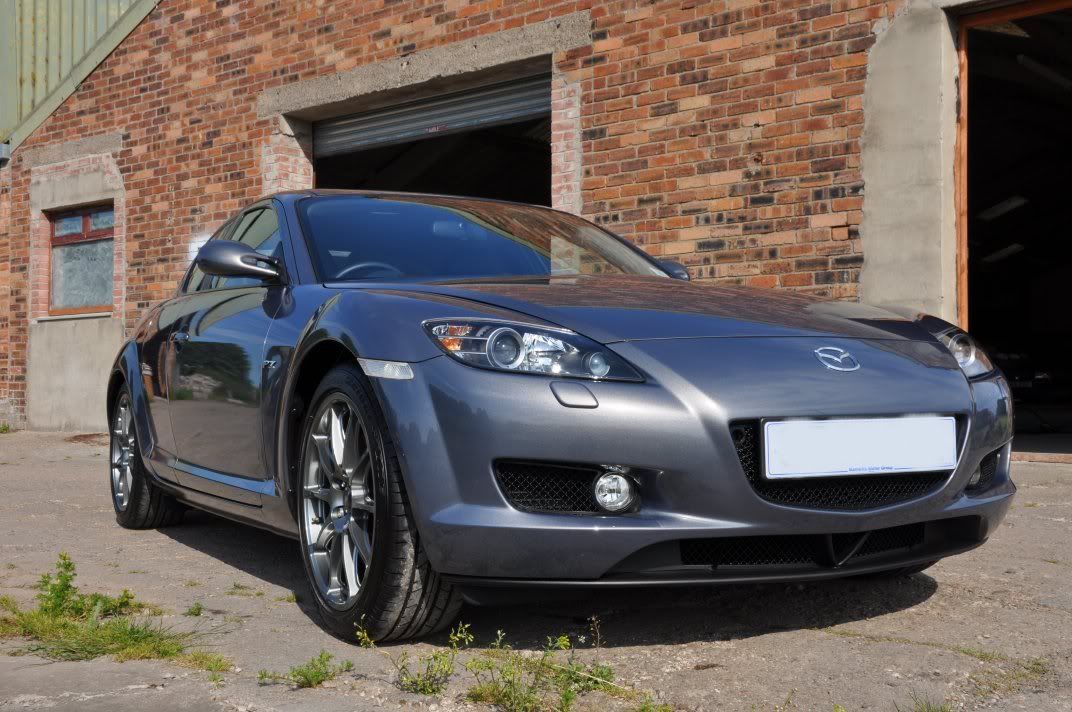

Perfection is a strong word, but the condition in which the car of today's detail turned up has to be the best I have seen - there was hardly a mark on the car, just a light hologram on a rear 3/4... Nearly three years old but only a few thousand miles, the current and previous owner clearly know how to wash the car...

The RX-8 as it arrived...

Once the wheels were cleaned with Bilberry and the arches with Meguiars All Purpose Cleaner, the car was foamed using Supa Snow Foam...

Rinsed, washed with two bucket method and Meguiars Shampoo Plus. Rinsed and then clayed.

The claying stage is where the transformation of this car began... the paint at the start, although looking swirl free, felt like sandpaper. Bilt Hamber Soft Clay effectively smoothed the paint...

The clay after just quarter of the bonnet, giving an idea of the level of contamination on the paint!

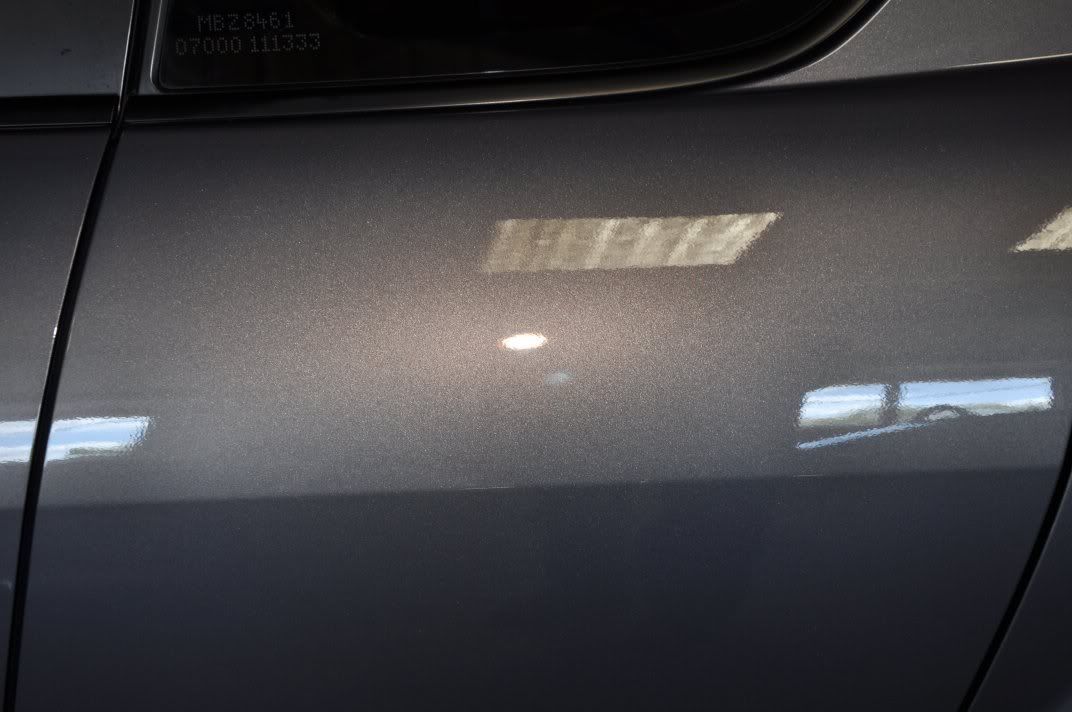

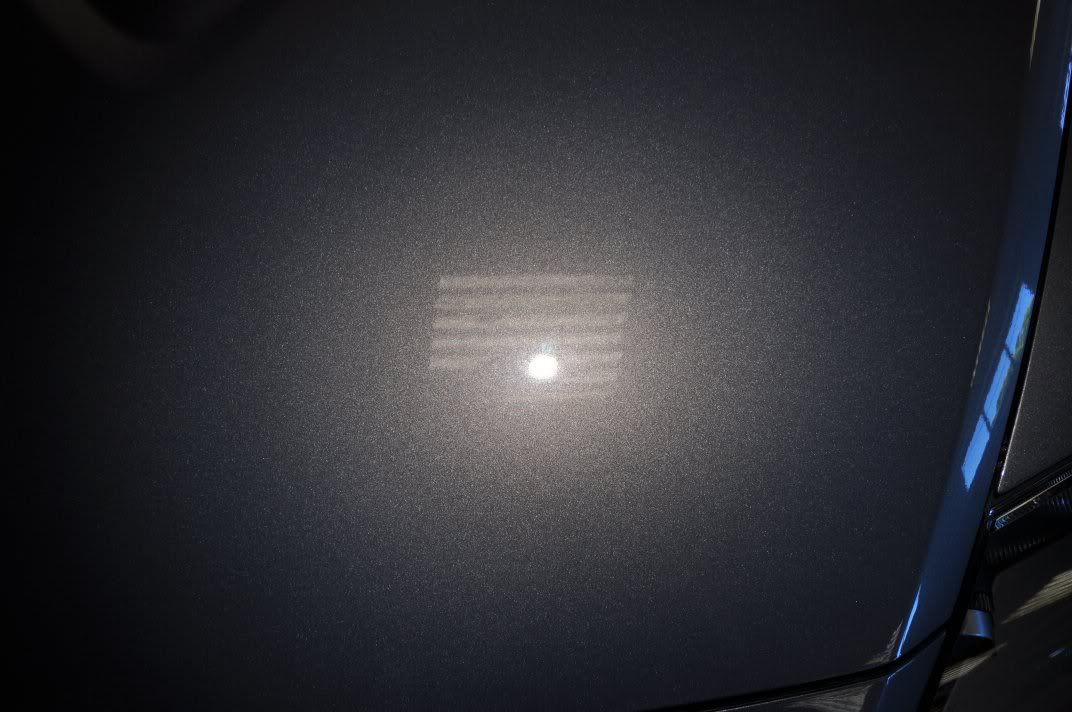

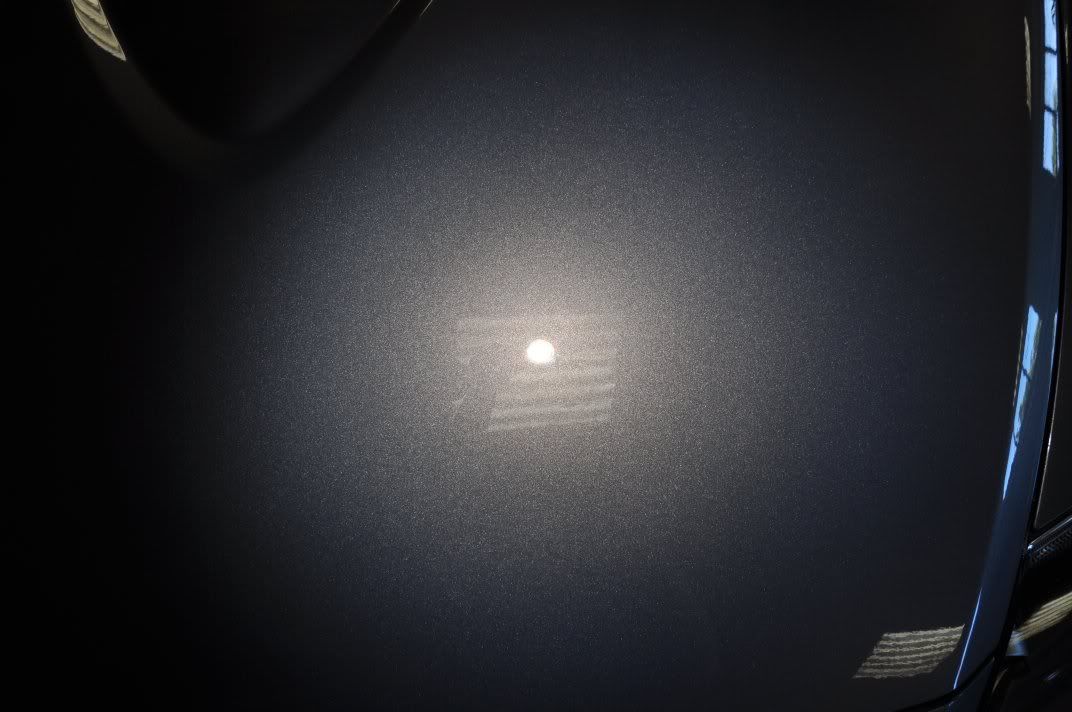

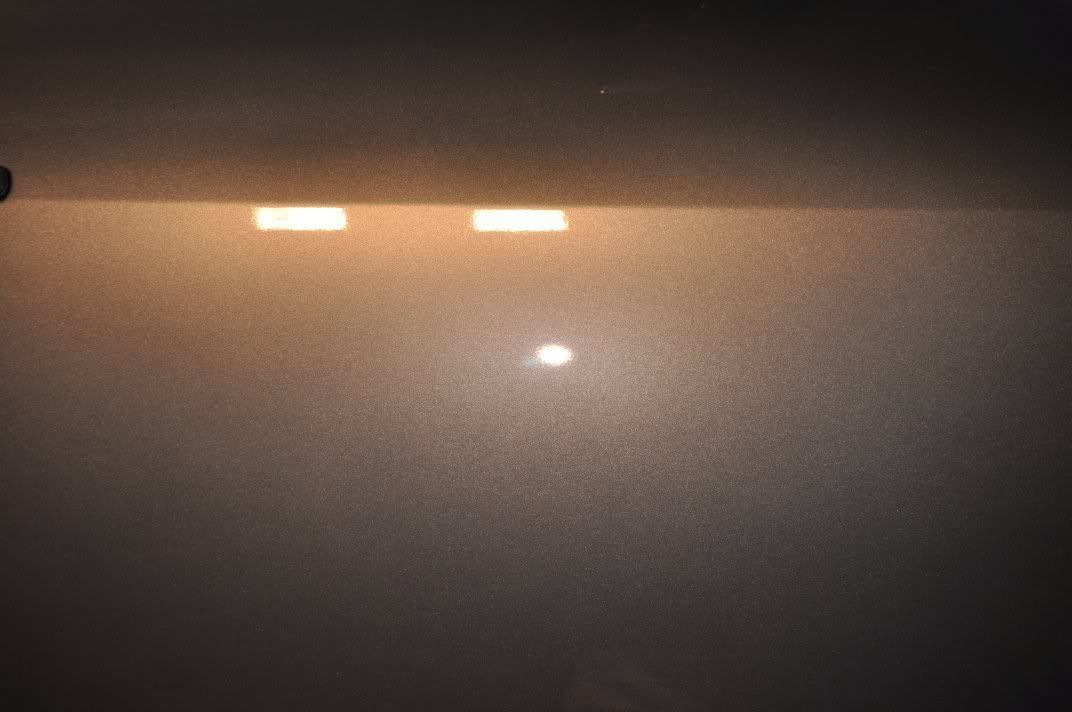

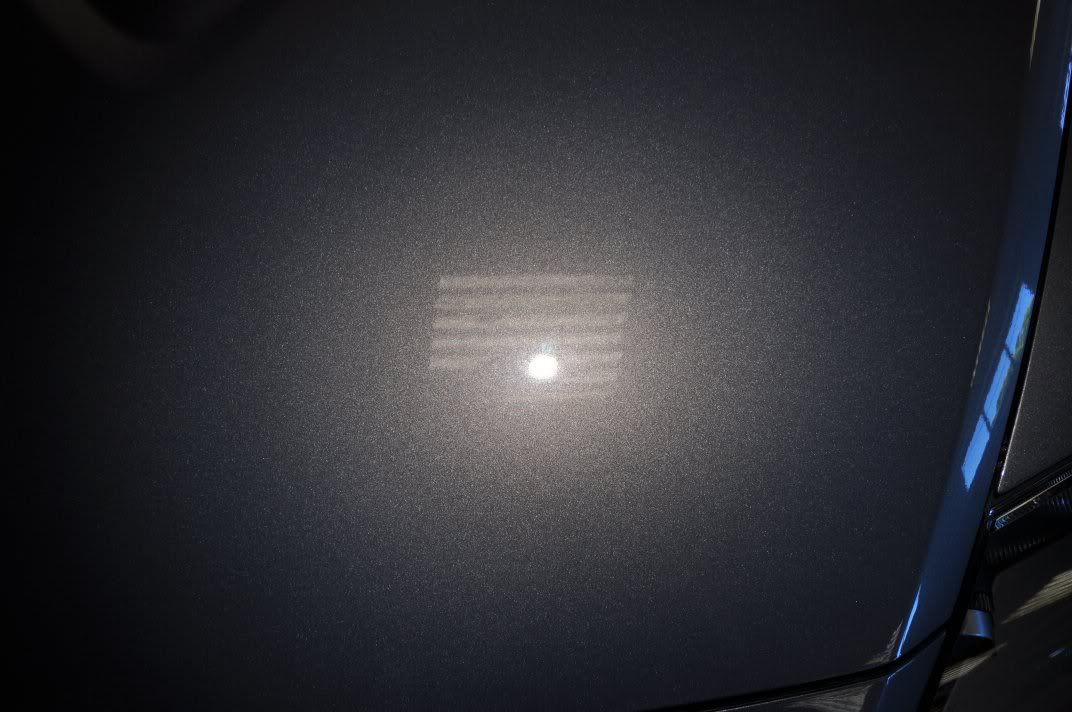

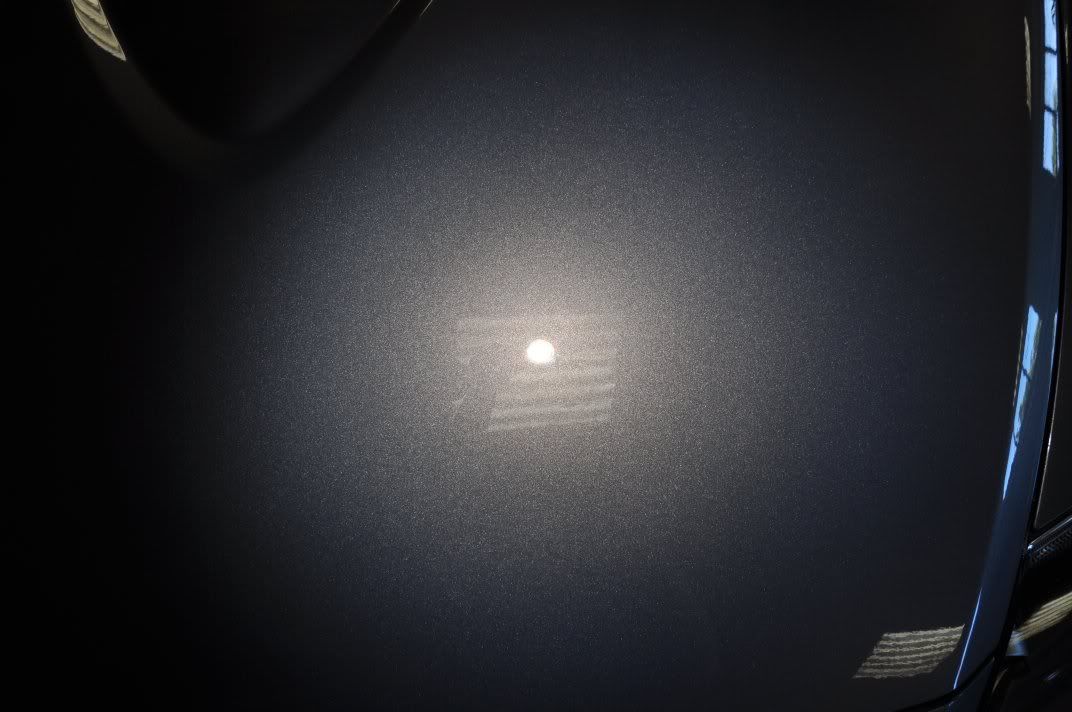

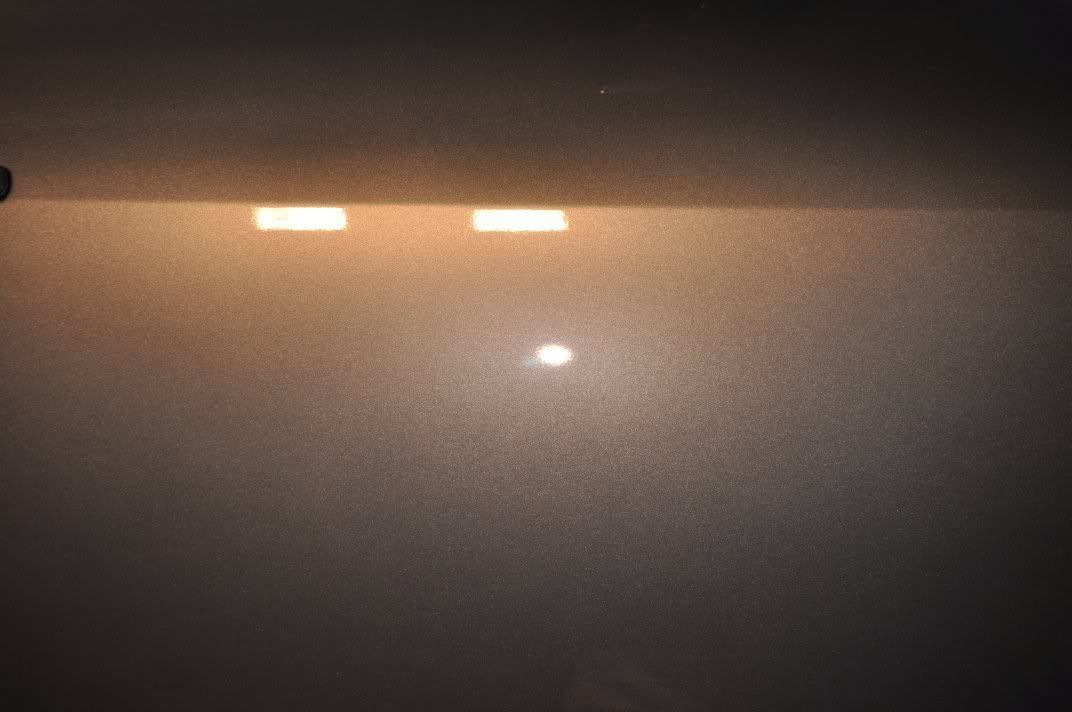

Once fully clayed it was time to assess the paintwork. It was clear at this stage how well looked after the car was - swirl free, the only issue was a slight lack of clarity and gloss to the finish:

Paint depth readings on this car were very typical of an RX-8: all under 100um, most around 80um:

Consistent paint though indicating that the car had not seen repair work or previous aggressive polishing.

No aggressive polishes were to be used today - with no swirls, only a refinement of the finish was required to bring out the gloss, enhance the clarity and allow the paint to ping a little more. Meguiars #205 Ultra Finishing Polish on a 3M Blue finishing pad fitted the bill ideally for this, applied as follows:

Here I focussed on the end passes on the soft Mazda paint, where the refining stage would be most important. Work time at 1500rpm was varied according to what the paint required, regions slightly hazy got a few extra passes to remove the haze before stepping down the speeds to refining.

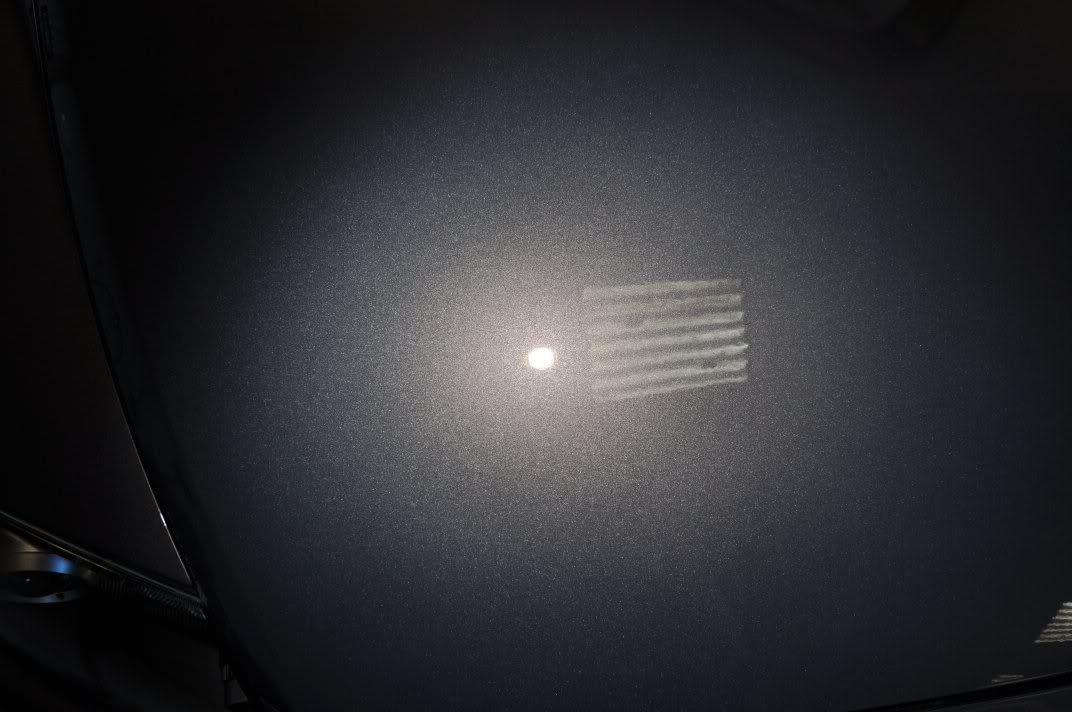

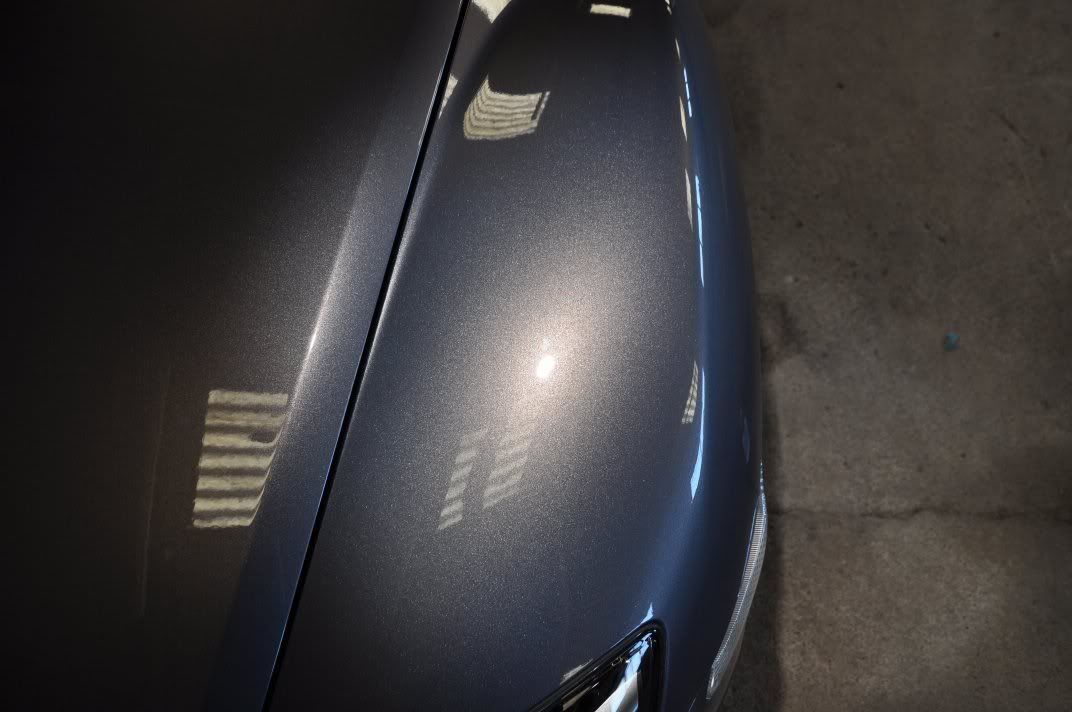

This resulted in an increase in clarity on the paint, allowing the paint flake to ping through a bit more clearly - there was now a yellow edge to the paint that could be seen...

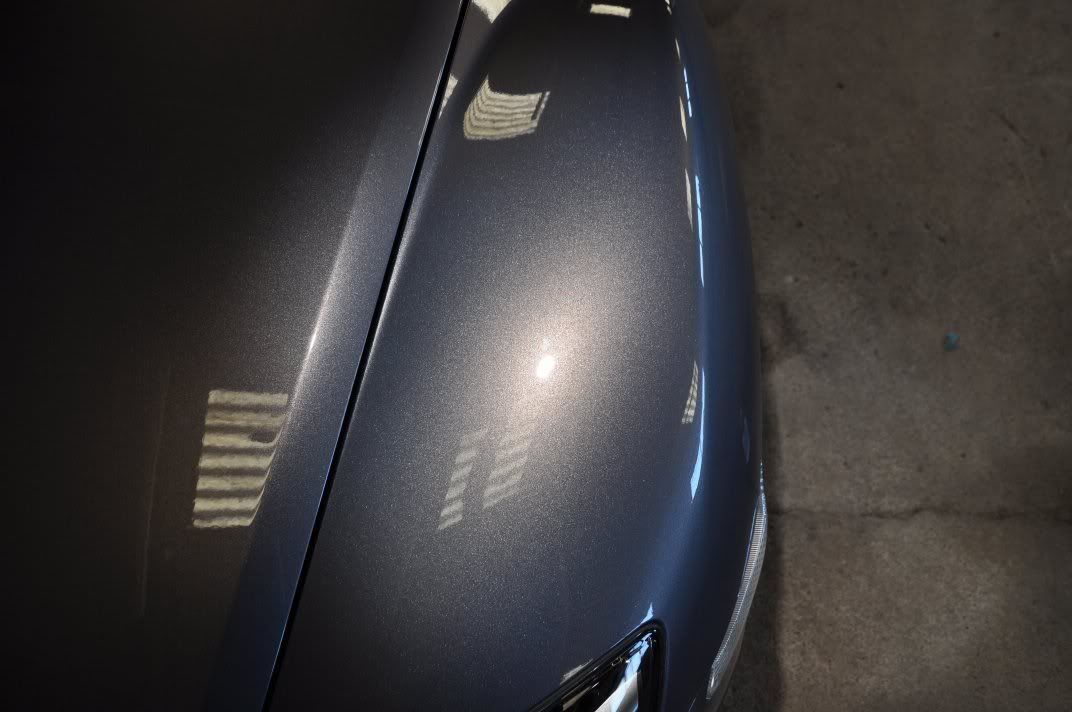

Lovely gloss being brought up on the finish...

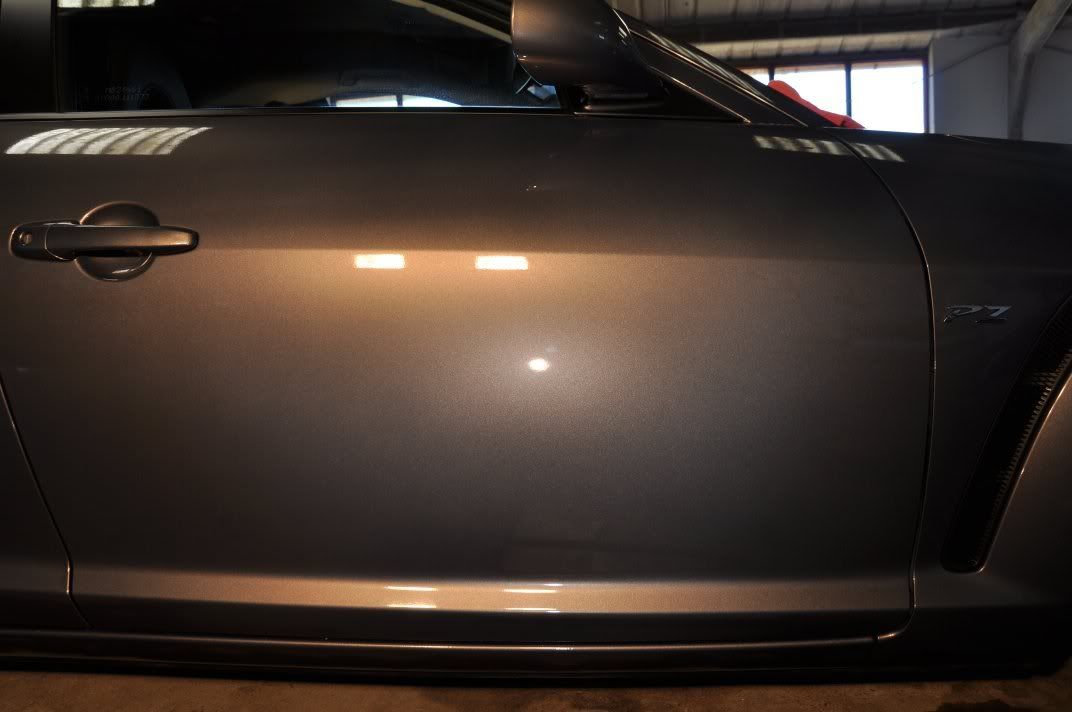

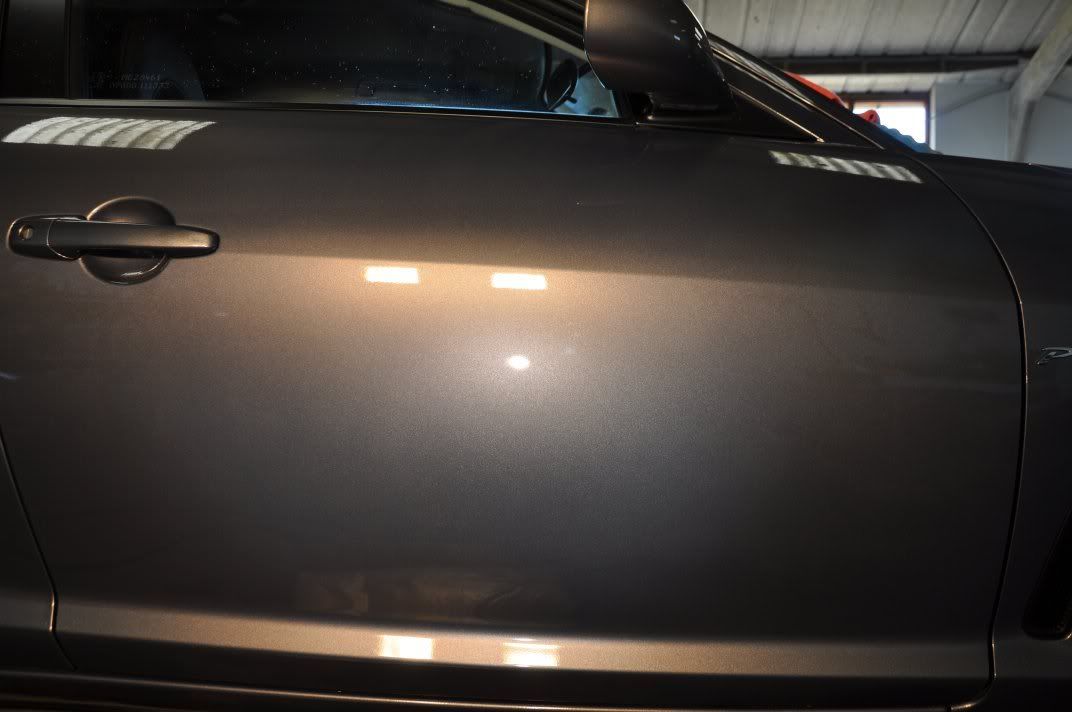

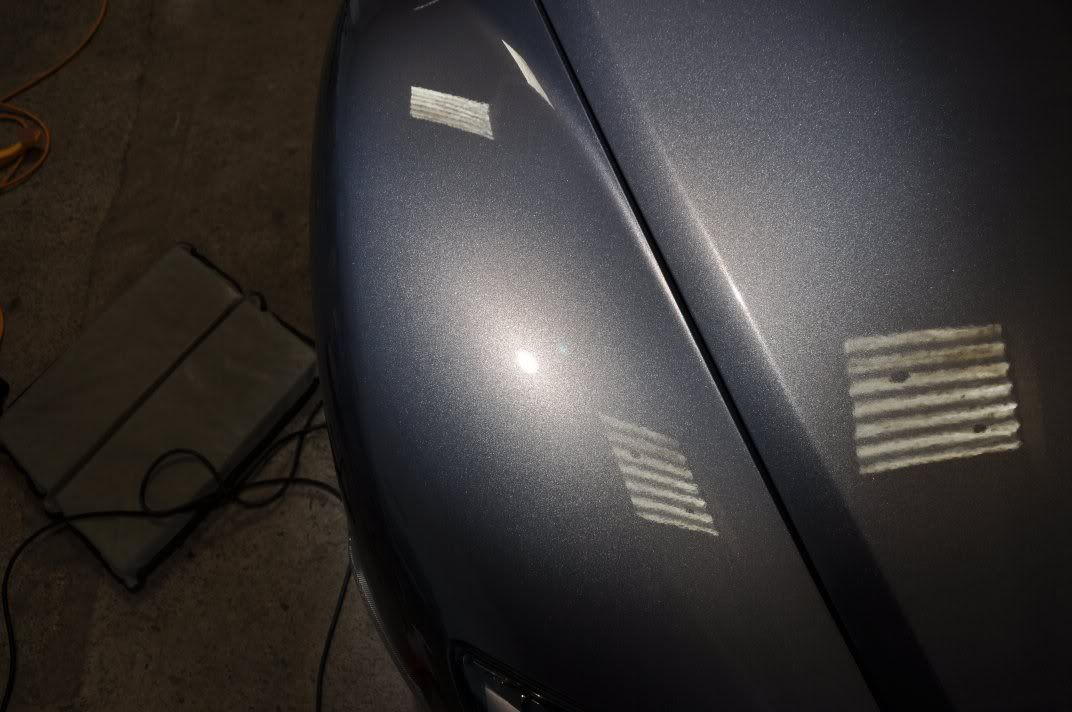

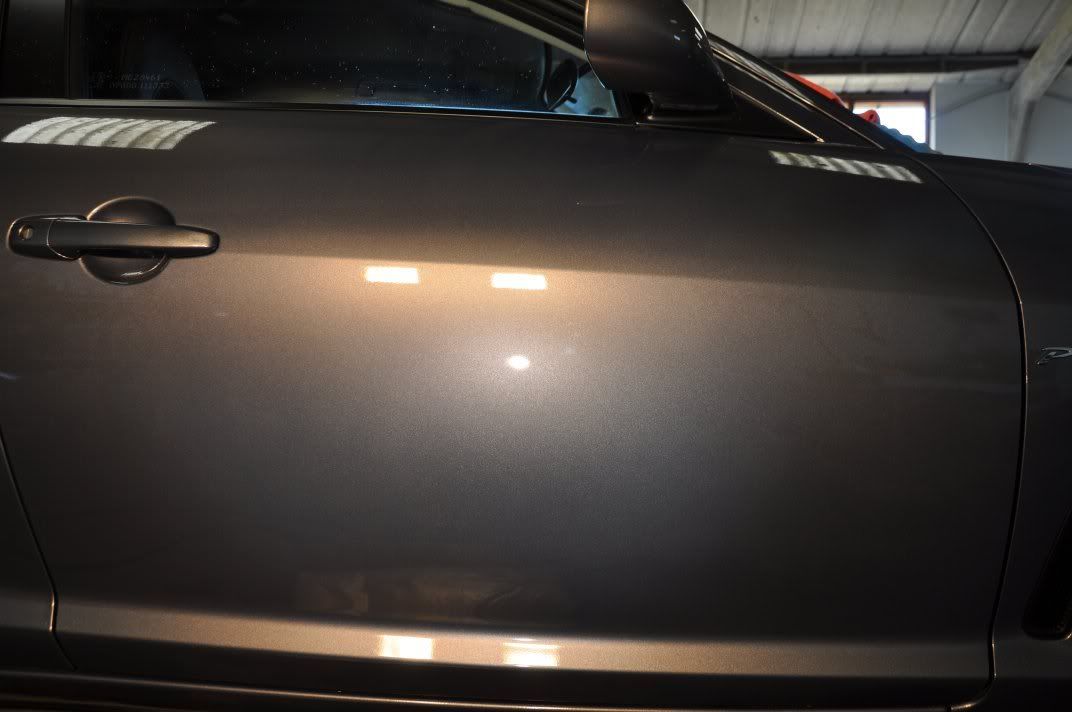

Driver's side, again only very minor hazing to be removed...

Paint thicknesses on the upper regions as normal...

But on the lower regions of the rear doors (aluminium) the readings raised a lot more concern!

34um?!! This was consistent as well, and very very thin paint. For this reason, I opted on this specific lower region only to cleanse the paint with Jeffs Prime Acyllic to ensure no mechanical abrasives removing any paint.

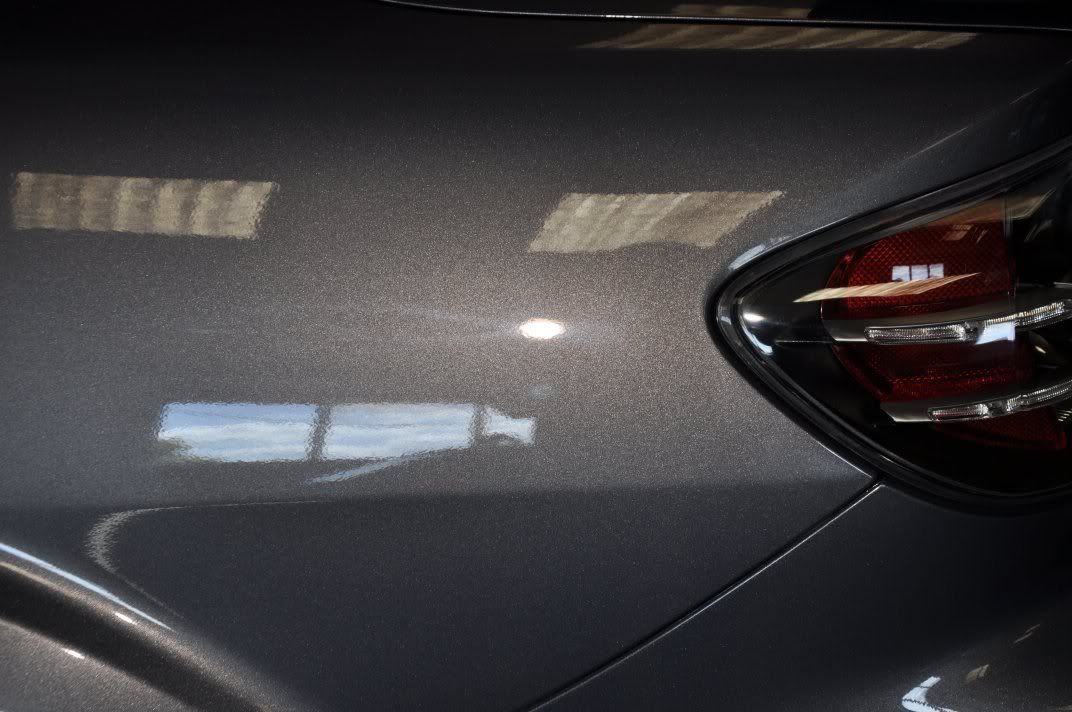

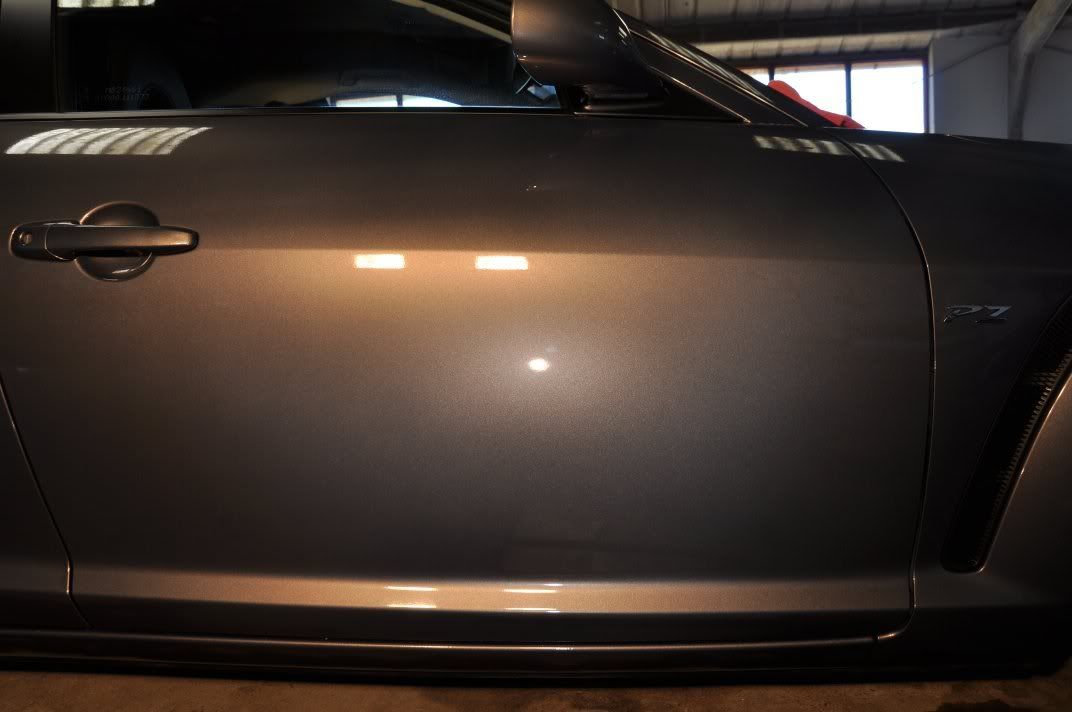

The thicker regions machine polished as the side of the car, giving the following:

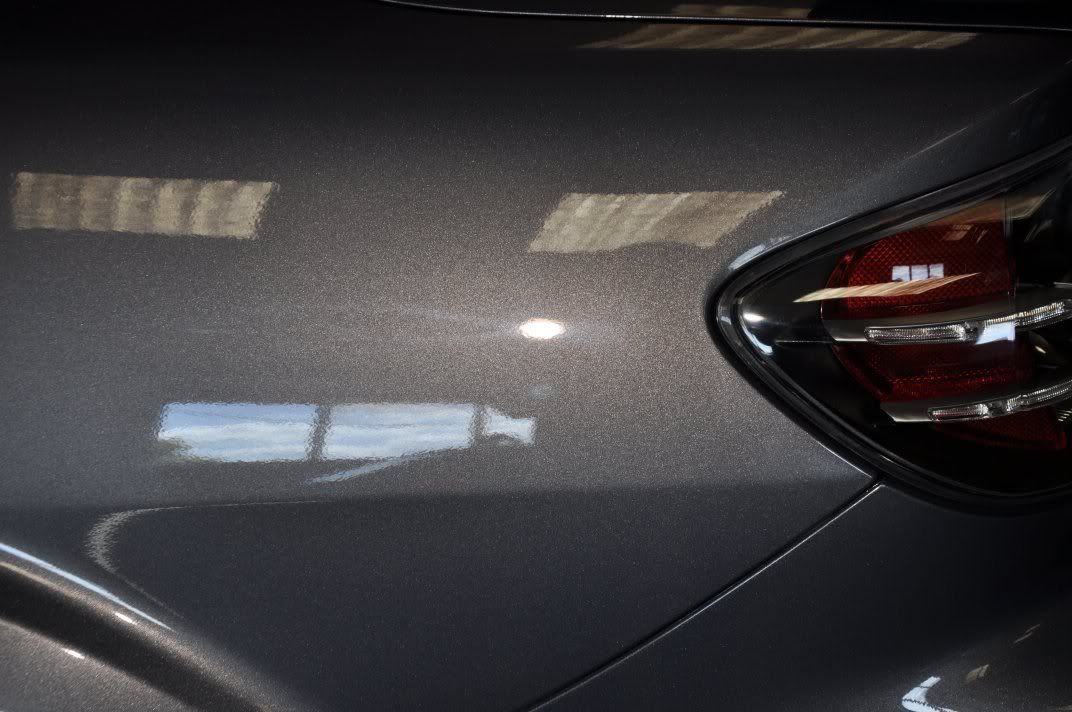

I was enjoying the look the paint was taking on - the improvements, though subtle, were allowing the flake features of the paint to come through at their best:

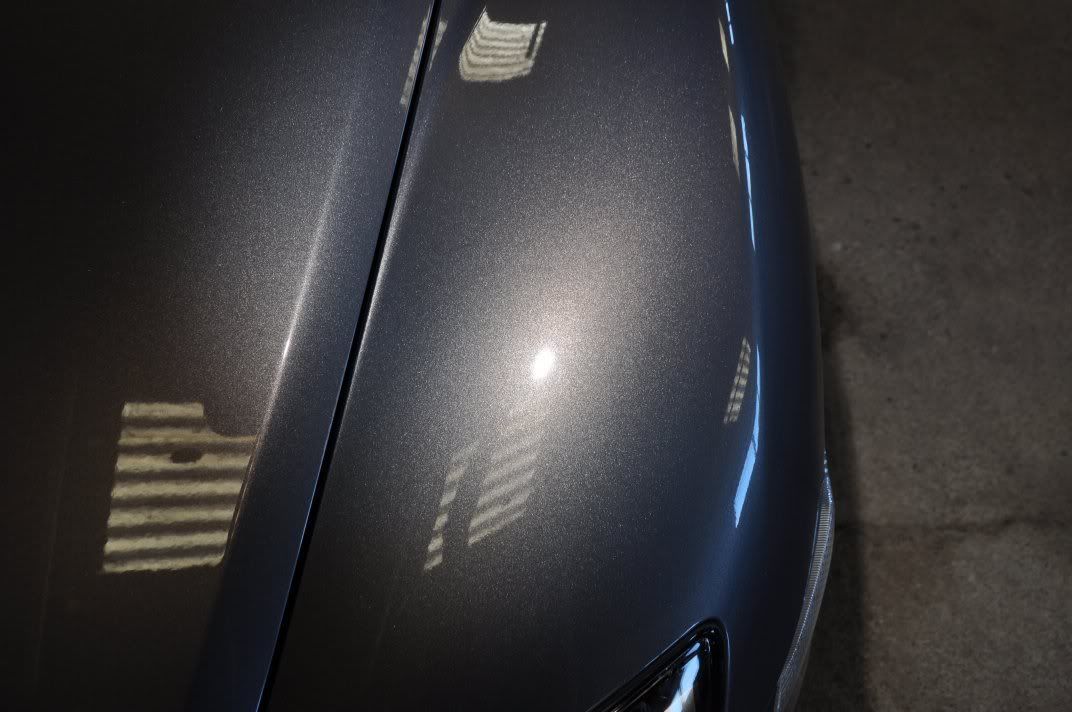

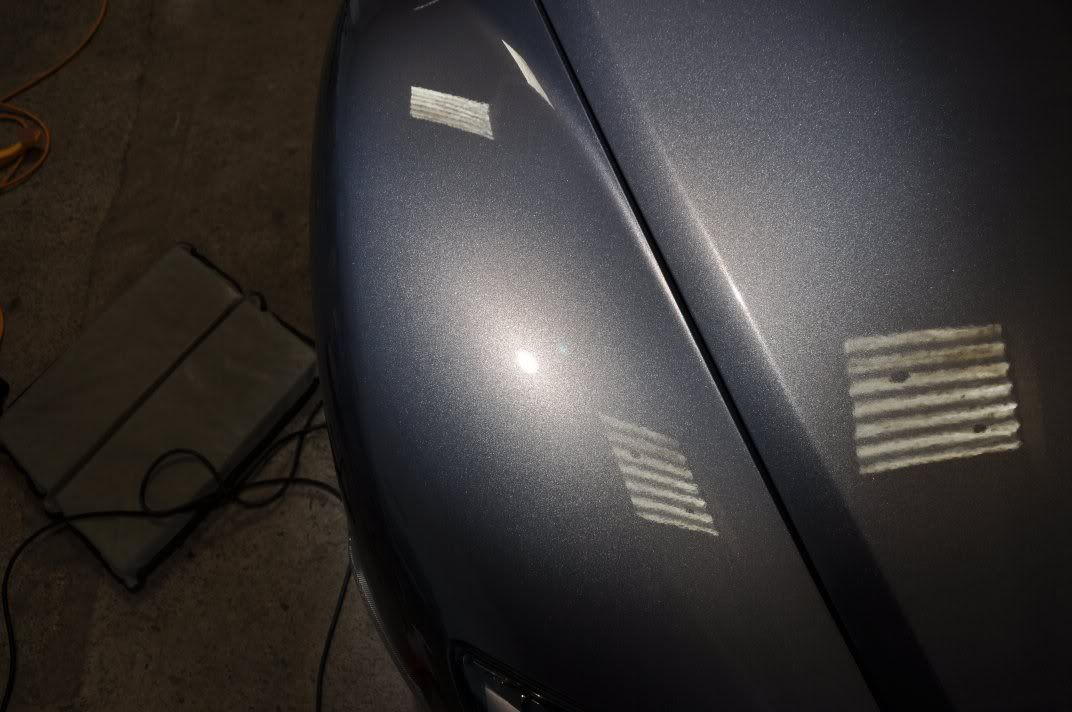

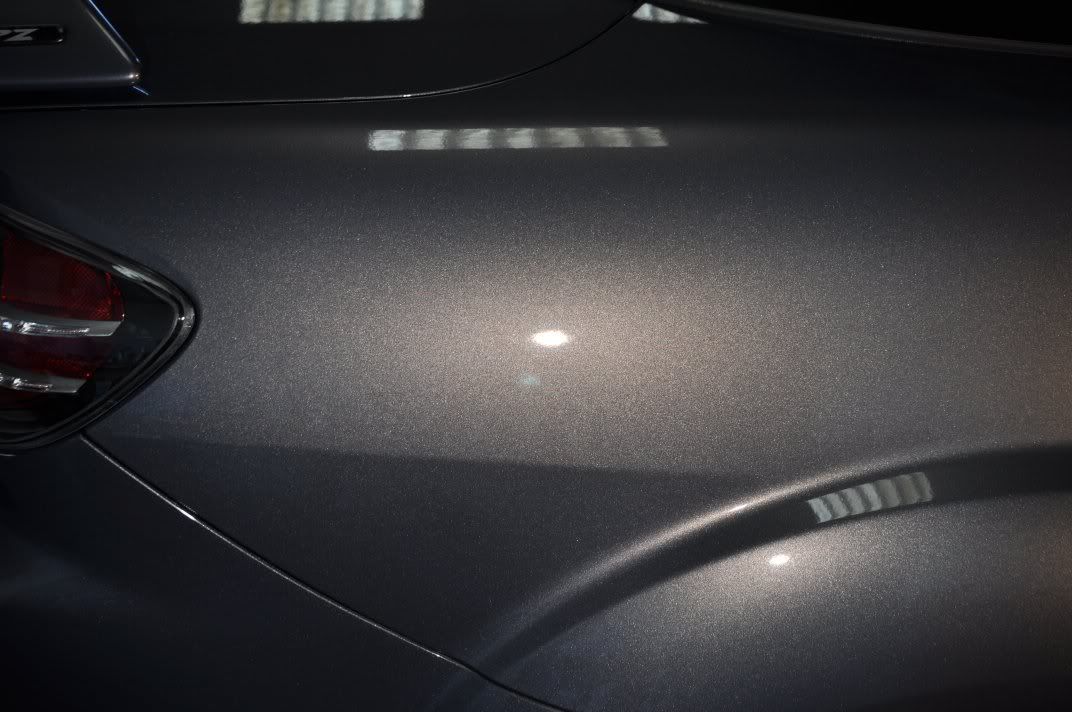

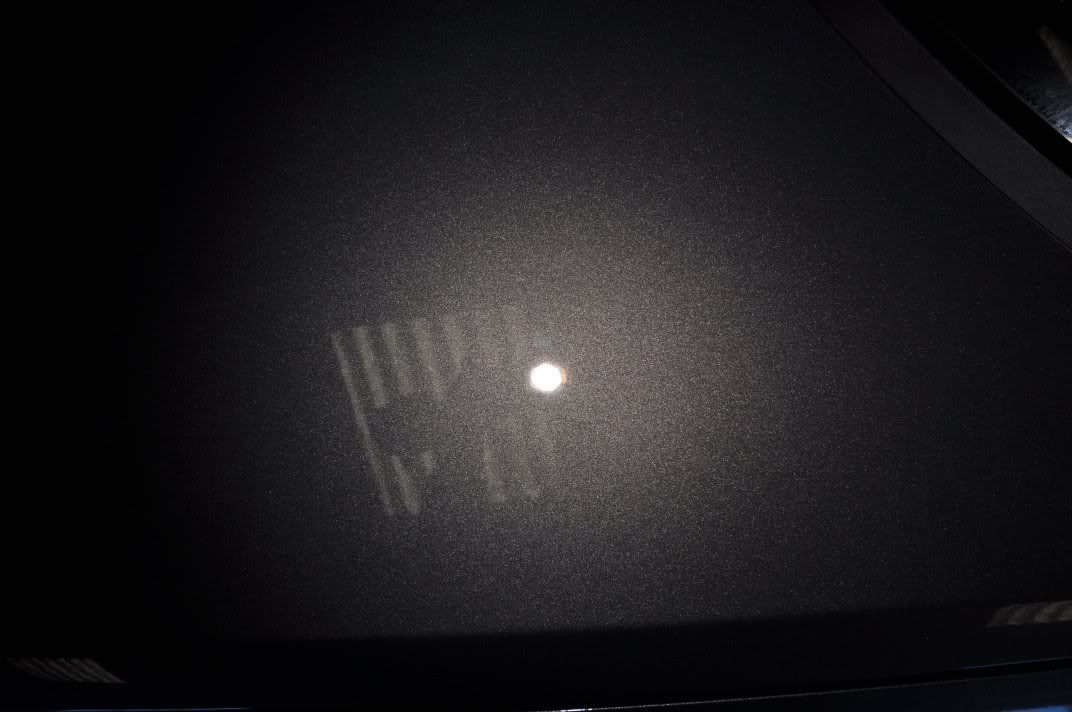

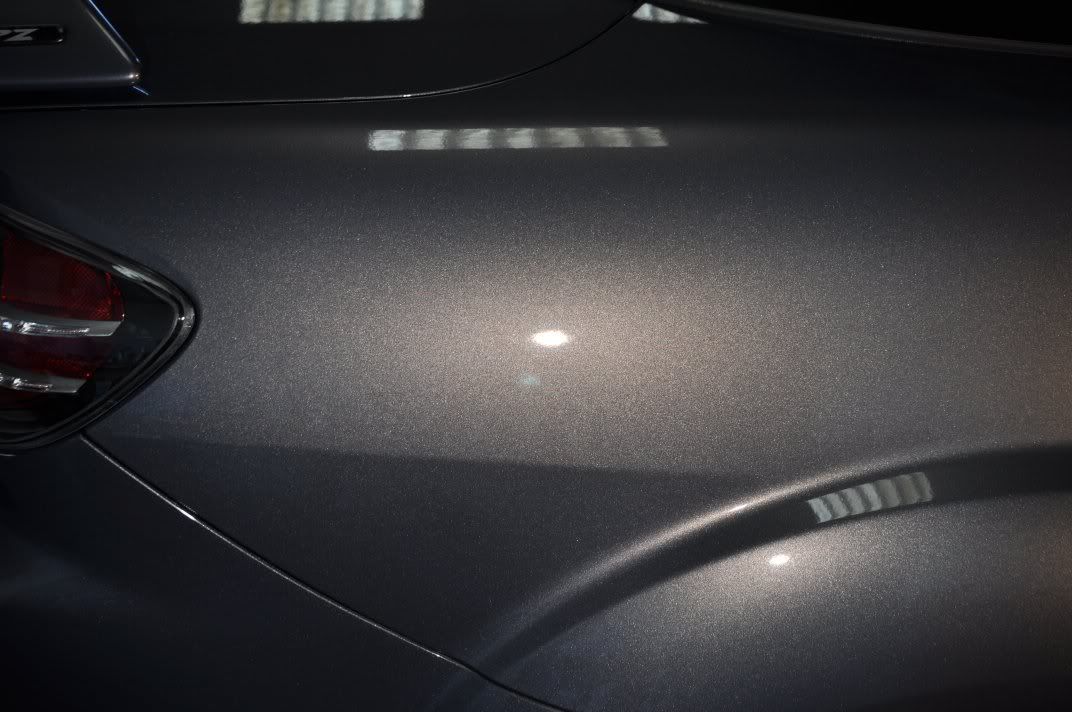

Only region on the paint that wasn't swirl free on arrival, the rear 3/4...

Yup, there are light machine tails there...

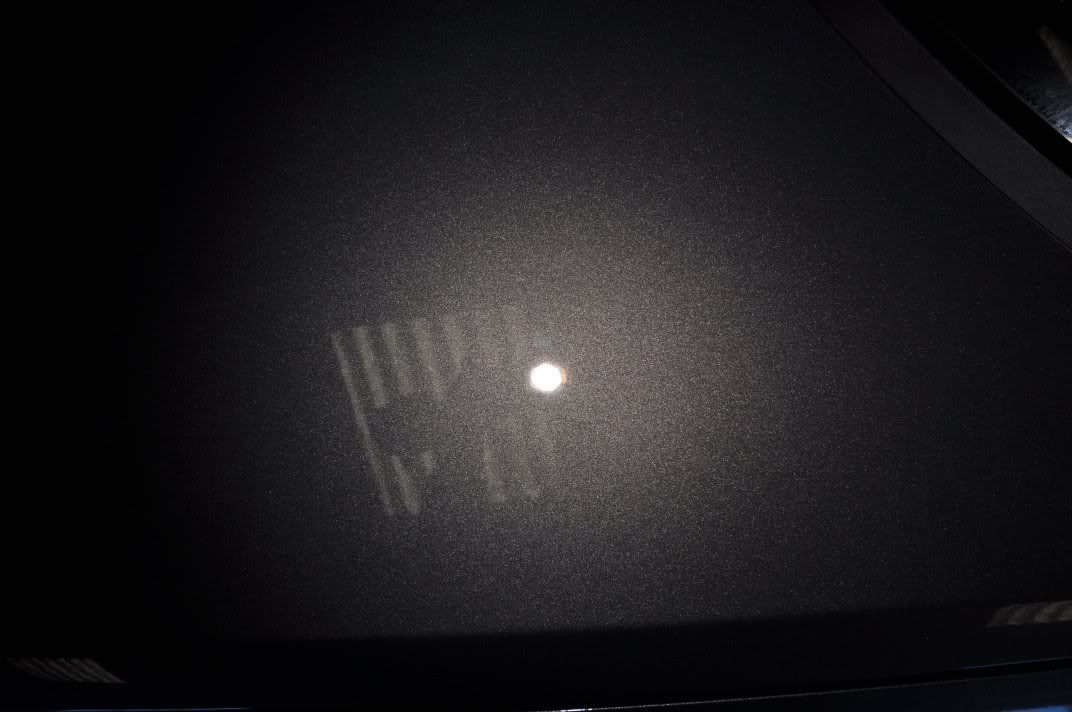

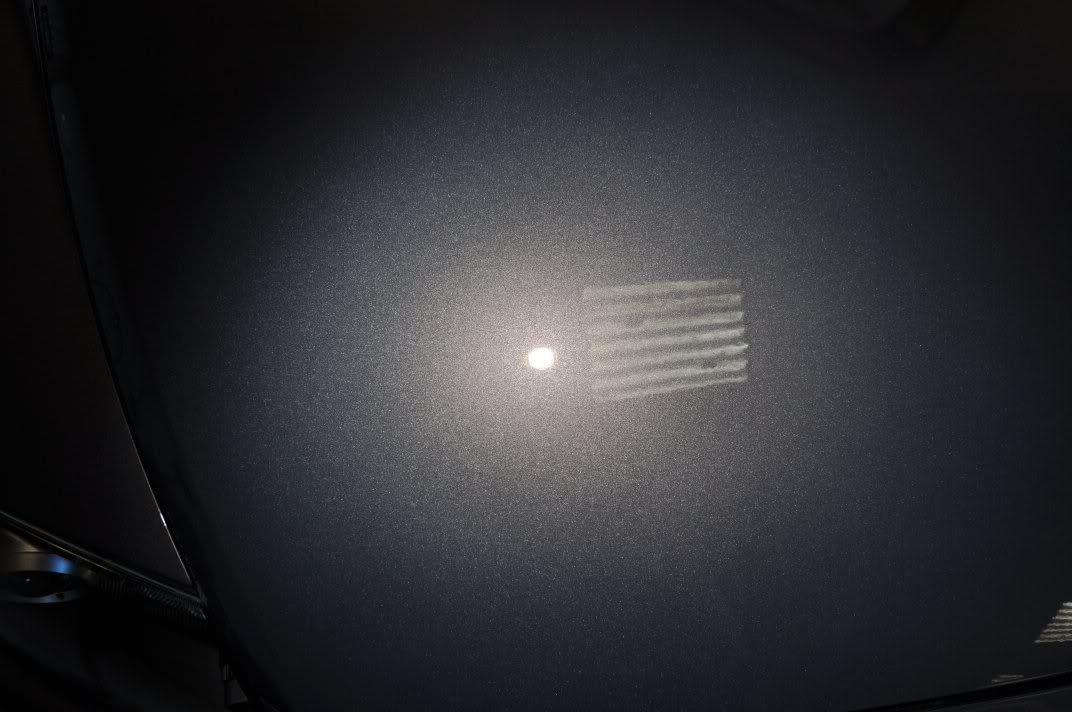

Easily removed using same process with #205 as rest of the car:

The RX-8 as it arrived...

Once the wheels were cleaned with Bilberry and the arches with Meguiars All Purpose Cleaner, the car was foamed using Supa Snow Foam...

Rinsed, washed with two bucket method and Meguiars Shampoo Plus. Rinsed and then clayed.

The claying stage is where the transformation of this car began... the paint at the start, although looking swirl free, felt like sandpaper. Bilt Hamber Soft Clay effectively smoothed the paint...

The clay after just quarter of the bonnet, giving an idea of the level of contamination on the paint!

Once fully clayed it was time to assess the paintwork. It was clear at this stage how well looked after the car was - swirl free, the only issue was a slight lack of clarity and gloss to the finish:

Paint depth readings on this car were very typical of an RX-8: all under 100um, most around 80um:

Consistent paint though indicating that the car had not seen repair work or previous aggressive polishing.

No aggressive polishes were to be used today - with no swirls, only a refinement of the finish was required to bring out the gloss, enhance the clarity and allow the paint to ping a little more. Meguiars #205 Ultra Finishing Polish on a 3M Blue finishing pad fitted the bill ideally for this, applied as follows:

- Spread at 600rpm

- Begin polishing at 1200rpm, increasing the pressure and ensuring the polish well spread

- Increased speed to 1500rpm, moderate pressure over the head, lightening off after a couple of minutes

- Refine at 1200rpm, light pressure, slow machine movements

- Burnish at 900rpm, supporting the weight of the Makita for lightest possible pressure and slow machine movements for three or four passes

Here I focussed on the end passes on the soft Mazda paint, where the refining stage would be most important. Work time at 1500rpm was varied according to what the paint required, regions slightly hazy got a few extra passes to remove the haze before stepping down the speeds to refining.

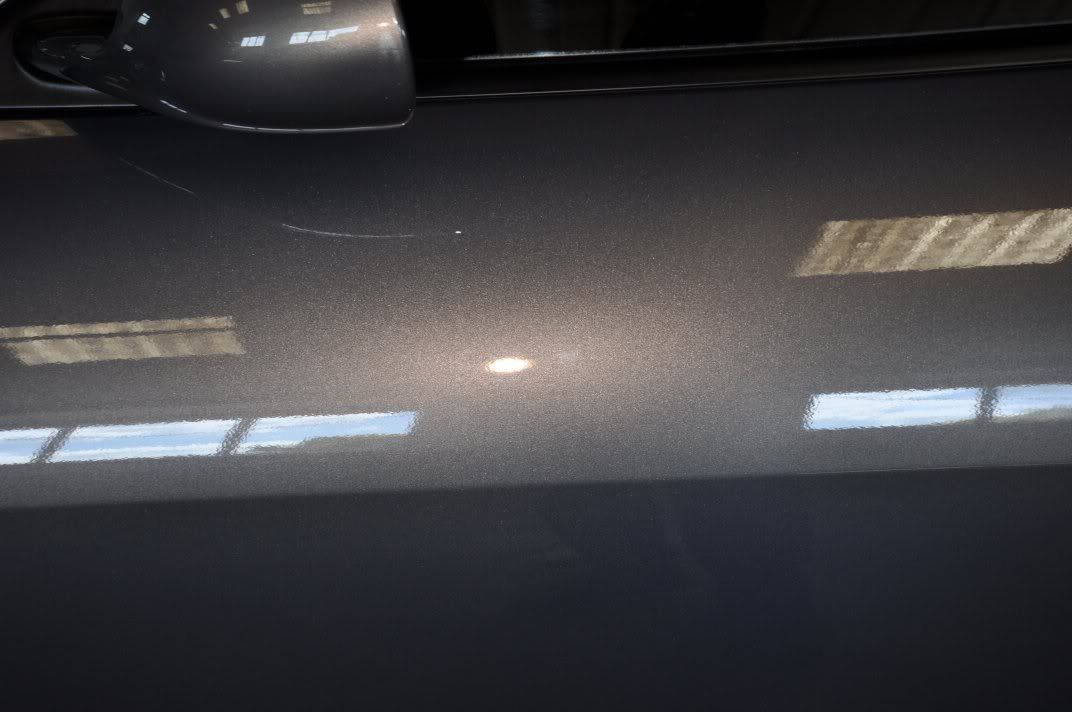

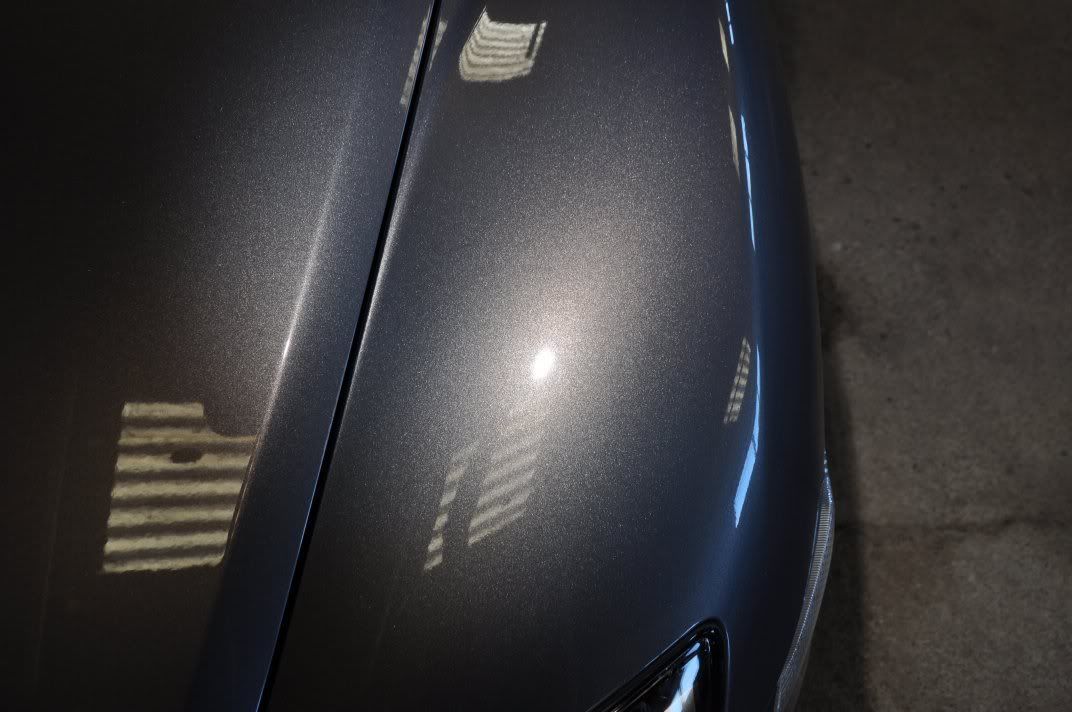

This resulted in an increase in clarity on the paint, allowing the paint flake to ping through a bit more clearly - there was now a yellow edge to the paint that could be seen...

Lovely gloss being brought up on the finish...

Driver's side, again only very minor hazing to be removed...

Paint thicknesses on the upper regions as normal...

But on the lower regions of the rear doors (aluminium) the readings raised a lot more concern!

34um?!! This was consistent as well, and very very thin paint. For this reason, I opted on this specific lower region only to cleanse the paint with Jeffs Prime Acyllic to ensure no mechanical abrasives removing any paint.

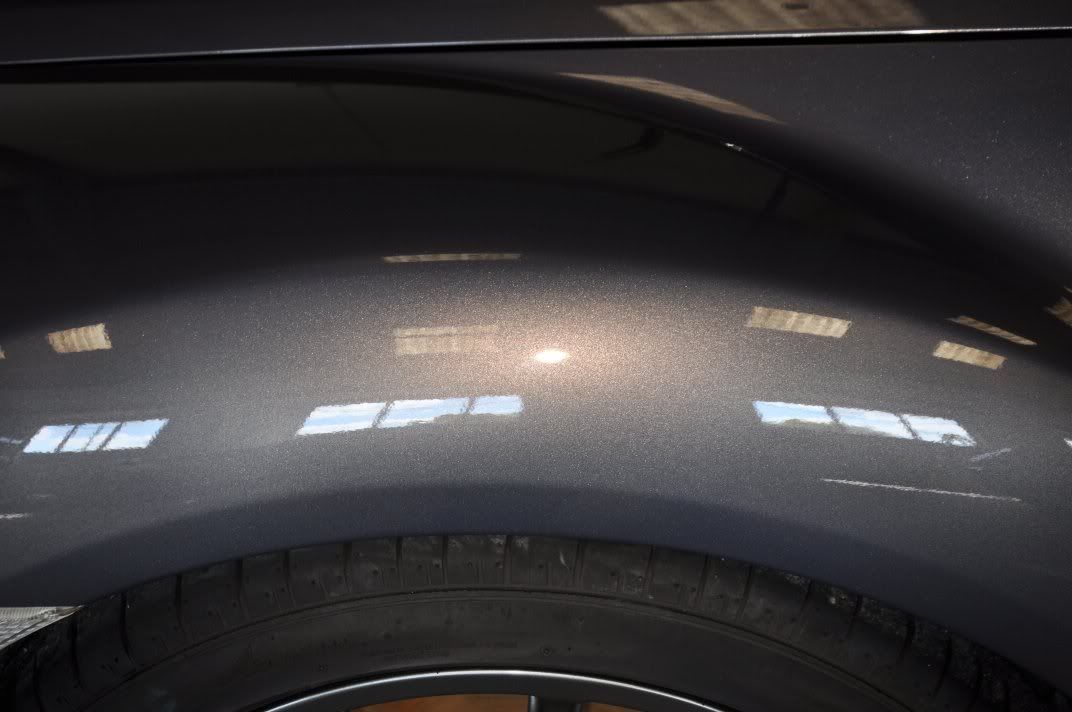

The thicker regions machine polished as the side of the car, giving the following:

I was enjoying the look the paint was taking on - the improvements, though subtle, were allowing the flake features of the paint to come through at their best:

Only region on the paint that wasn't swirl free on arrival, the rear 3/4...

Yup, there are light machine tails there...

Easily removed using same process with #205 as rest of the car: