THE FLEX XC 3401 VRG POLISHER REVIEW by WK446

Version 1.01 Last Updated 07-10-03

Well, my Flex XC 3401 VRG finally arrived and thankfully with the black (vs. red) backing plate. Kudos go out to the board members that sourced the unit out and provided information to assist others. Even though I'm fairly new to Autopia, I have been detailing for 15+ years as a hobby. I have the following polishers that I can compare directly, namely the Makita 9227, Porter Cable 7424, and the Metabo PE12-175 (currently on hiatus).

First, some photos of the Flex:

DESCRIPTION

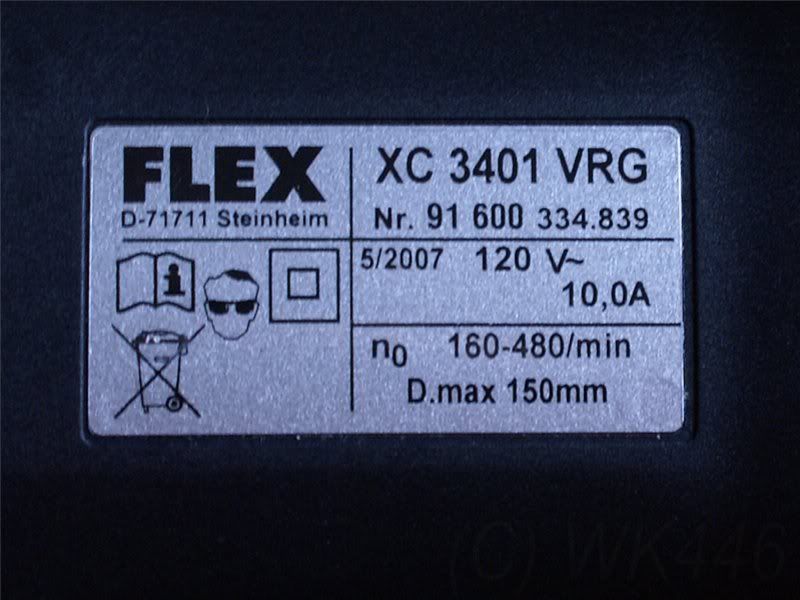

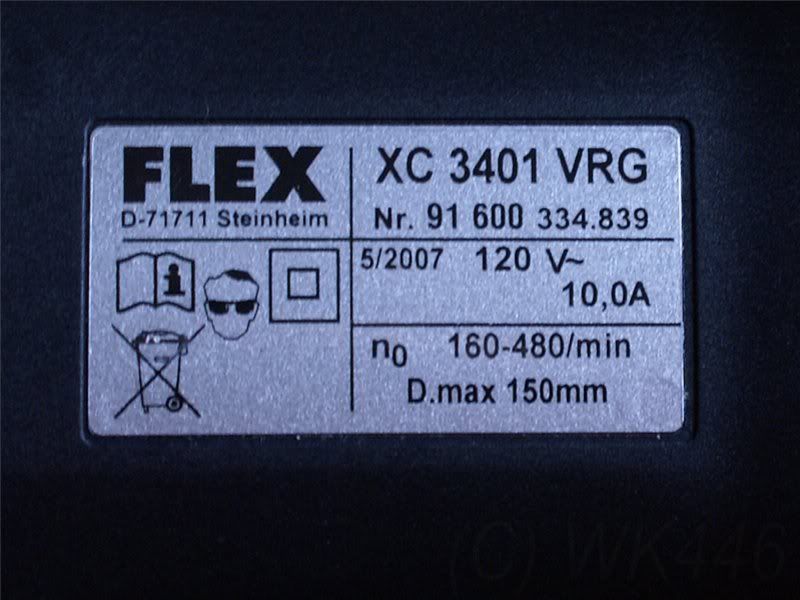

The Flex XC 3401 VRG is a dual action (DA) polisher but has an operating speed up to 480 RPM and a powerful motor. Dual action polishers are safer for use on automobile paint because they do not operate in the same fashion as a rotary polisher. The most popular DA polisher is the Porter Cable 7424. Due to the Flex's construction, it can correct more difficult paint imperfections which were the sole domain of the rotary polisher while at the same time, offer the "safety blanket" of DA polishers.

PACKAGING CONTENTS

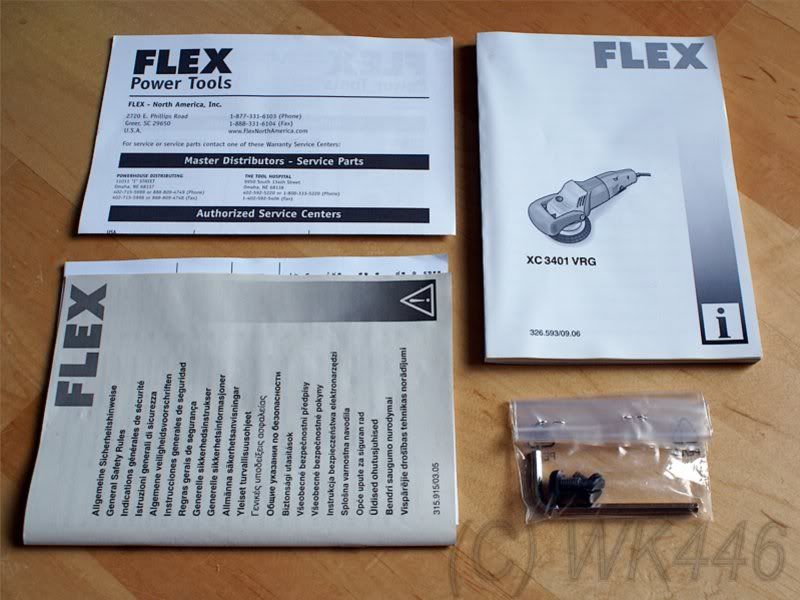

The Flex comes with the following items: manual, service documentation, general safety guide, hex wrench, 2 additional bolts.

BUILD QUALITY AND WEIGHT

The Flex is very well built and the quality of the construction materials is first rate. The Flex is made in Germany. In order of build quality, with the best quality to the right, I would rate them subjectively as:

Porter Cable -> Makita/Metabo (tie) -> Flex

The weight of the unit, somewhat surprised me. In order of lightest to the heaviest, the scale is as follows:

Porter Cable 7424 -> Metabo PE 12-175 -> Makita 9227 -> Flex XC 3401 VRG.

The weight is well balanced however, albeit, slightly forward biased. Without using a scale, the Flex is a hair heavier than the Makita. I have also used and owned the Dewalt 849 and the Flex is far lighter than it. None of the rotary units I have used can come close to the weight of the Metabo.

SIZE

The Flex is about 16" long, 6" wide, and 4.5" high. The size is very manageable and is relatively compact. On a scale from smallest to largest:

Porter Cable -> Metabo -> Flex -> Makita

A comparion of the Porter Cable, Flex, and Makita. The Metabo is on hiatus...

The Flex and the Porter Cable

The Flex and the Makita

ERGONOMICS

For right handed users, the Flex is very ergonomically-friendly, with the pistol grip handle, large trigger placed naturally and the speed dial easily accessible by thumb. There is also a useful trigger lock that also falls readily to one's thumb. If you have used the Makita, than you will adapt quickly to this unit. The trigger pull and feel of the Flex is slightly better than the Makita. I think this is largely due to the larger surface area of the trigger. For left handed users, the location of the speed dial and the trigger lock will bring the Flex slightly down on ergonomics. To increase speed with the speed dial, roll the dial clockwise. To reduce speed, roll the speed dial counter-clockwise.

On an ergonomics scale from worst to best (for right handed users):

Metabo -> Porter Cable -> Makita/Flex (tie)

The frontal holder/grip is particularly helpful and is similar to the one on the Metabo:

SAFETY

The Flex is equiped with carbon brushes in it's motor. When these brushes eventually wear down, the unit will stop for safety's sake. The top mounted spindle lock button is recessed and cannot be accidently pressed. The Flex has overheating protection - if it senses that the unit is getting too hot, it will dial down the speed automatically. The Flex is equipped with a power cable that has a two-prong plug end and has a very soft and flexible rubber jacket. It has UL and CSA certification.

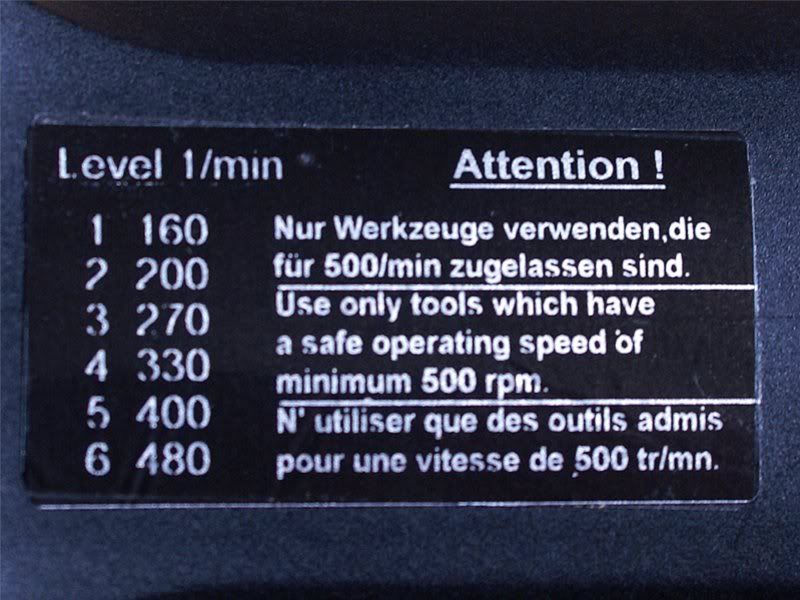

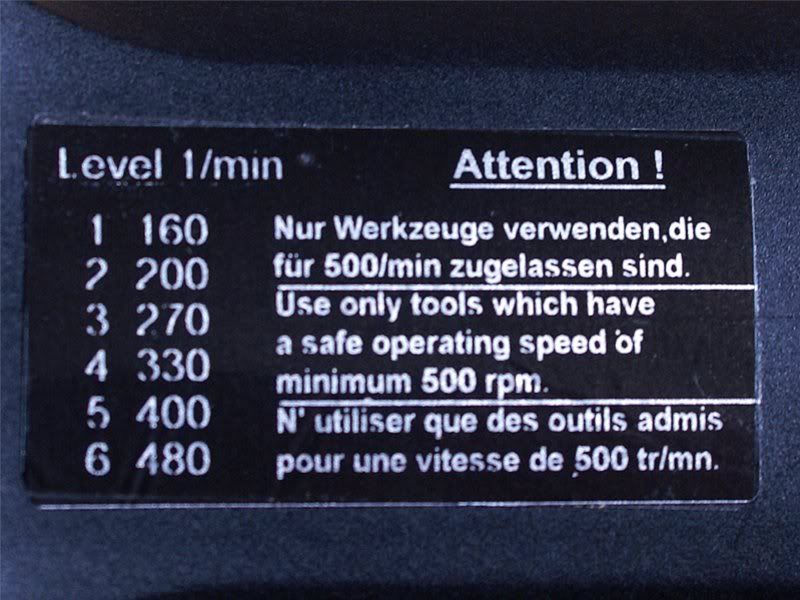

SPEED SETTINGS

There are 6 settings on the speed dial, labeled 1 (160 RPM) to 6 (480 RPM). The manual does not mention OPM (Orbits per Minute).

At speeds of 1 to 2, vibration is hardly noticeable, increasing slightly as the speed creeps towards 6. I don't find the vibration intrusive, but I have yet to conduct long term detailing with the Flex, so check back for an update at a later time. The front holder seems to dampen the vibration.

NOISE

In comparison to the Porter Cable, the Flex is perhaps 5% louder on lower speeds, increasing to 10-15% at higher speeds. I wear hearing protection when detailing so I only offer this information to those that do not.

BACKING PLATE AND PADS

The backing plate is designed by Flex to work with this particular unit. The backing plate is made of a hard ABS type of plastic, that is fluted on the rear. There is velcro that covers the front of the backing plate from edge to edge, save the center of the backing plate where a hex retaining bolt is present. Upon pressing the velcro firmly with my fingers, I can trace small circles in the central circumference of the backing plate - likely designed to save weight. My Flex came with the black backing plate. Some Flex owners have reported their units were shipped with a red backing plate. Apparently the red backing plate had problems with the adhesive that fastened the velcro to the backing plate failing. If you happen to have a unit with the red backing plate, contact Flex.

Caveat: Since the backing plate on the Flex is rigid, there is no "give" like those on urethane backing plates. This is especially evident when hitting a tight area/angle.

With respect to pad sizes, I use 4" pads, 6" Meguiar's pads, and 7.5" beveled edge type pads with my other polishers. The Flex is unable to use the 4" pads because it lacks specific backing plate for them. The 6" pads from Meguiar's are a favorite of mine because I have been using them with different polishers for such a long time. However, the Flex will not work properly with 6" pads as the backing plate is exactly the same size as the pad itself. The backing plate holds my 6.5" Lake Country CCS pads firmly, but leaves an edge of 1/8". As long as the user is cautious, I don't find this an issue, primarily because of the thickness of the CCS pads. 7.5" pads with the beveled edge fit very well on the backing plate and leave a good safety pocket. The Flex should have more than enough torque for this size of pad.

Meguiar's 6" (beige), 6.5" Lake Country CCS pad (black/white), 7.5" beveled edge (red/blue)

With a 6" Meguiar's Pad. **NOT RECOMMENDED**

With a 6.5" Lake Country CCS Pad:

With a 7.5" Beveled Edge Pad:

HEAT

The Flex seems well ventilated with 2 pairs of vents on either side of the unit: just forward of the trigger lock and just behind the handle on the front of the unit. During a 2 hours session, I did not notice the Flex becoming noticeably warm or uncomfortable. This is also true of the Makita and to a lesser extent, the Porter Cable. The Metabo is the opposite - the vents are in the general area where the user grips it, and as such, may not be getting enough air to cool it properly. My working extension cord is 12 gauge and no other auxilary devices or plugged into my extension. It has been suggested by some that the Metabo is picky about power, due to it's high current draw and the most powerful motor of this lot. I believe in using high quality extension cords, by 12 guage should be more than adequate for these type of tools

On a scale from coolest running to hottest running:

Makita/Flex (tie) -> Porter Cable -> Metabo

More to come...

Version 1.01 Last Updated 07-10-03

Well, my Flex XC 3401 VRG finally arrived and thankfully with the black (vs. red) backing plate. Kudos go out to the board members that sourced the unit out and provided information to assist others. Even though I'm fairly new to Autopia, I have been detailing for 15+ years as a hobby. I have the following polishers that I can compare directly, namely the Makita 9227, Porter Cable 7424, and the Metabo PE12-175 (currently on hiatus).

First, some photos of the Flex:

DESCRIPTION

The Flex XC 3401 VRG is a dual action (DA) polisher but has an operating speed up to 480 RPM and a powerful motor. Dual action polishers are safer for use on automobile paint because they do not operate in the same fashion as a rotary polisher. The most popular DA polisher is the Porter Cable 7424. Due to the Flex's construction, it can correct more difficult paint imperfections which were the sole domain of the rotary polisher while at the same time, offer the "safety blanket" of DA polishers.

PACKAGING CONTENTS

The Flex comes with the following items: manual, service documentation, general safety guide, hex wrench, 2 additional bolts.

BUILD QUALITY AND WEIGHT

The Flex is very well built and the quality of the construction materials is first rate. The Flex is made in Germany. In order of build quality, with the best quality to the right, I would rate them subjectively as:

Porter Cable -> Makita/Metabo (tie) -> Flex

The weight of the unit, somewhat surprised me. In order of lightest to the heaviest, the scale is as follows:

Porter Cable 7424 -> Metabo PE 12-175 -> Makita 9227 -> Flex XC 3401 VRG.

The weight is well balanced however, albeit, slightly forward biased. Without using a scale, the Flex is a hair heavier than the Makita. I have also used and owned the Dewalt 849 and the Flex is far lighter than it. None of the rotary units I have used can come close to the weight of the Metabo.

SIZE

The Flex is about 16" long, 6" wide, and 4.5" high. The size is very manageable and is relatively compact. On a scale from smallest to largest:

Porter Cable -> Metabo -> Flex -> Makita

A comparion of the Porter Cable, Flex, and Makita. The Metabo is on hiatus...

The Flex and the Porter Cable

The Flex and the Makita

ERGONOMICS

For right handed users, the Flex is very ergonomically-friendly, with the pistol grip handle, large trigger placed naturally and the speed dial easily accessible by thumb. There is also a useful trigger lock that also falls readily to one's thumb. If you have used the Makita, than you will adapt quickly to this unit. The trigger pull and feel of the Flex is slightly better than the Makita. I think this is largely due to the larger surface area of the trigger. For left handed users, the location of the speed dial and the trigger lock will bring the Flex slightly down on ergonomics. To increase speed with the speed dial, roll the dial clockwise. To reduce speed, roll the speed dial counter-clockwise.

On an ergonomics scale from worst to best (for right handed users):

Metabo -> Porter Cable -> Makita/Flex (tie)

The frontal holder/grip is particularly helpful and is similar to the one on the Metabo:

SAFETY

The Flex is equiped with carbon brushes in it's motor. When these brushes eventually wear down, the unit will stop for safety's sake. The top mounted spindle lock button is recessed and cannot be accidently pressed. The Flex has overheating protection - if it senses that the unit is getting too hot, it will dial down the speed automatically. The Flex is equipped with a power cable that has a two-prong plug end and has a very soft and flexible rubber jacket. It has UL and CSA certification.

SPEED SETTINGS

There are 6 settings on the speed dial, labeled 1 (160 RPM) to 6 (480 RPM). The manual does not mention OPM (Orbits per Minute).

At speeds of 1 to 2, vibration is hardly noticeable, increasing slightly as the speed creeps towards 6. I don't find the vibration intrusive, but I have yet to conduct long term detailing with the Flex, so check back for an update at a later time. The front holder seems to dampen the vibration.

NOISE

In comparison to the Porter Cable, the Flex is perhaps 5% louder on lower speeds, increasing to 10-15% at higher speeds. I wear hearing protection when detailing so I only offer this information to those that do not.

BACKING PLATE AND PADS

The backing plate is designed by Flex to work with this particular unit. The backing plate is made of a hard ABS type of plastic, that is fluted on the rear. There is velcro that covers the front of the backing plate from edge to edge, save the center of the backing plate where a hex retaining bolt is present. Upon pressing the velcro firmly with my fingers, I can trace small circles in the central circumference of the backing plate - likely designed to save weight. My Flex came with the black backing plate. Some Flex owners have reported their units were shipped with a red backing plate. Apparently the red backing plate had problems with the adhesive that fastened the velcro to the backing plate failing. If you happen to have a unit with the red backing plate, contact Flex.

Caveat: Since the backing plate on the Flex is rigid, there is no "give" like those on urethane backing plates. This is especially evident when hitting a tight area/angle.

With respect to pad sizes, I use 4" pads, 6" Meguiar's pads, and 7.5" beveled edge type pads with my other polishers. The Flex is unable to use the 4" pads because it lacks specific backing plate for them. The 6" pads from Meguiar's are a favorite of mine because I have been using them with different polishers for such a long time. However, the Flex will not work properly with 6" pads as the backing plate is exactly the same size as the pad itself. The backing plate holds my 6.5" Lake Country CCS pads firmly, but leaves an edge of 1/8". As long as the user is cautious, I don't find this an issue, primarily because of the thickness of the CCS pads. 7.5" pads with the beveled edge fit very well on the backing plate and leave a good safety pocket. The Flex should have more than enough torque for this size of pad.

Meguiar's 6" (beige), 6.5" Lake Country CCS pad (black/white), 7.5" beveled edge (red/blue)

With a 6" Meguiar's Pad. **NOT RECOMMENDED**

With a 6.5" Lake Country CCS Pad:

With a 7.5" Beveled Edge Pad:

HEAT

The Flex seems well ventilated with 2 pairs of vents on either side of the unit: just forward of the trigger lock and just behind the handle on the front of the unit. During a 2 hours session, I did not notice the Flex becoming noticeably warm or uncomfortable. This is also true of the Makita and to a lesser extent, the Porter Cable. The Metabo is the opposite - the vents are in the general area where the user grips it, and as such, may not be getting enough air to cool it properly. My working extension cord is 12 gauge and no other auxilary devices or plugged into my extension. It has been suggested by some that the Metabo is picky about power, due to it's high current draw and the most powerful motor of this lot. I believe in using high quality extension cords, by 12 guage should be more than adequate for these type of tools

On a scale from coolest running to hottest running:

Makita/Flex (tie) -> Porter Cable -> Metabo

More to come...