JohnKleven

New member

I see more and more people using a Festool on here. How does the power of the Festool compare to a Flex? Any major benefits of either one?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

JohnKleven said:I see more and more people using a Festool on here. How does the power of the Festool compare to a Flex? Any major benefits of either one?

WhyteWizard said:I've run the Flex, Festool, Bosch, and Makita side by side.

I have three of the Makitas. I use them hard every day and I like spreading the stress around and being able to loan one out so people I talk to can try them and see if they can run it.

The Festool would be second choice, Bosch, third and Flex last. Just based on how effective each tool is, the amount of time it takes to get the finished result.

Robert

tdekany said:Which Makita is your first choice? So the festool is better at correcting than the flex3401?

WhyteWizard said:I've run the Flex, Festool, Bosch, and Makita side by side.

I have three of the Makitas. I use them hard every day and I like spreading the stress around and being able to loan one out so people I talk to can try them and see if they can run it.

The Festool would be second choice, Bosch, third and Flex last. Just based on how effective each tool is, the amount of time it takes to get the finished result.

Robert

WhyteWizard said:The Makita BO6040. In my opinion, from the amount of heat generated and because of the action of the various machines I rated them according to how well they'd work for correction. In my work, I use the rotary, at the moment one of my 9227 c Makitas, or the Hitachi - nosier but more powerful and slightly lighter - SP18VA for correction.

Because I work with my polish in the pad, not slurrying around on the surface, I can see through the polish residue and see when the scratches are gone and also when a scratch is too deep to remove.

There is an alternative opinion that heat is bad, for those people there's a dial on the Makita that goes up and down. Also, when running that machine, because it spins the opposite direction, counter clockwise instead of clockwise, to the rotary, I've found it's helpful to hold the machine with my hands reversed, that is, right hand on top, left hand on the handle, using my left index finger for the power tab.

Robert

tdekany said:Does the makita RO has more torque than the flex? How does it correct faster?

WhyteWizard said:The difference is in how the two machine get their forced rotation. The Flex is basically a random orbital that forces the pad to spin by interfacing the backing plate with the housing. So, the orbit goes one direction the pad spins the other.

The Makita has planetary gears that force the pad to spin the same direction as the orbit which creates more revolutions per minute and more movement between the pad and the paint.

The Festool's movement is similar to the Makita's but it's orbit is slightly smaller.

Robert

The Makita has planetary gears that force the pad to spin the same direction as the orbit which creates more revolutions per minute and more movement between the pad and the paint.

TH0001 said:I don’t know which is more powerful, the Makita or the Flex, because I have very limited experience with the Makita, and only moderate (compared to many others) experience with the Flex.

However there are a couple of points that I think are relevant to this discussion.

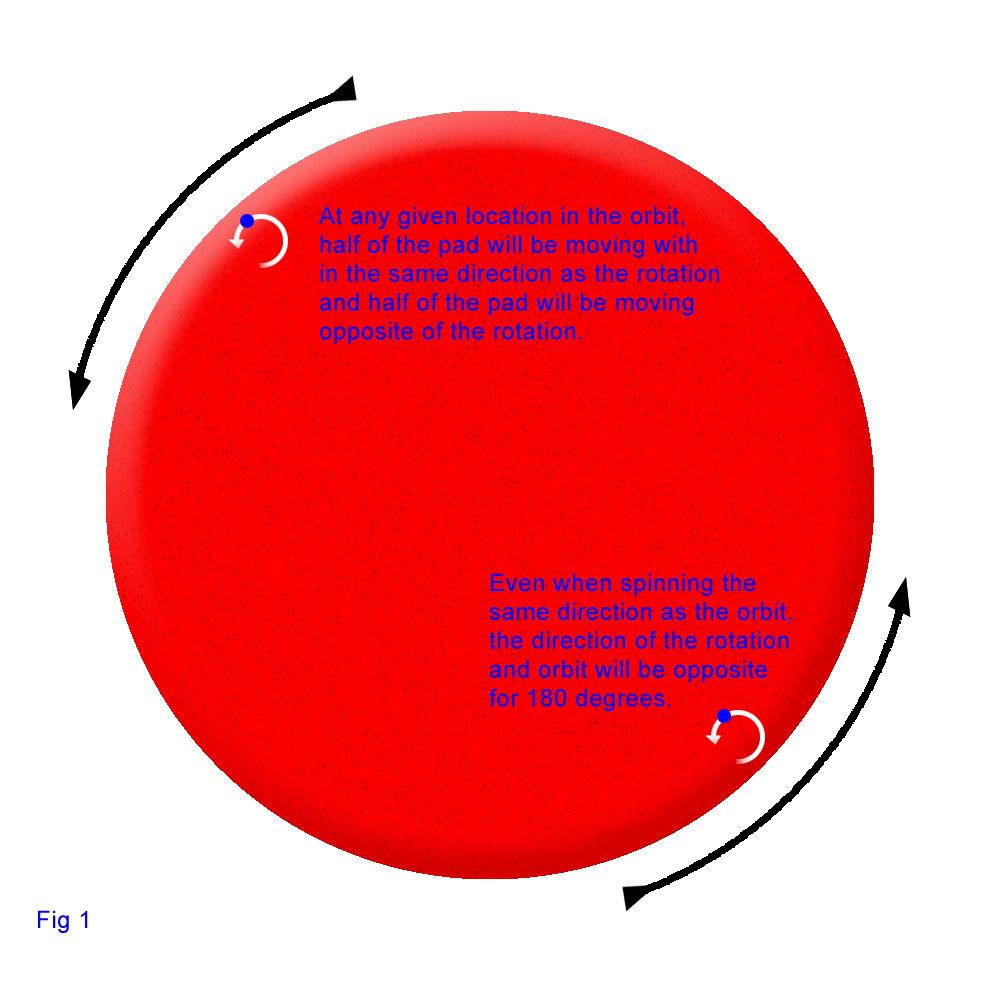

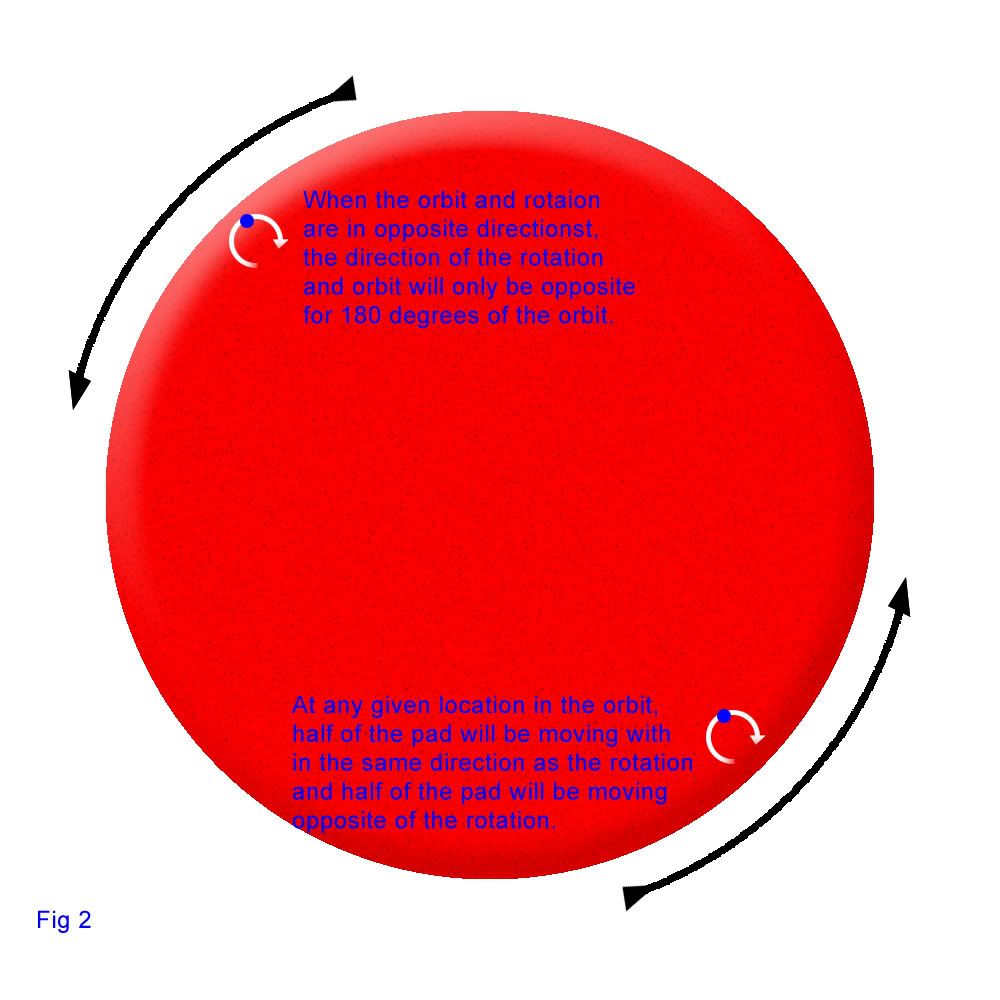

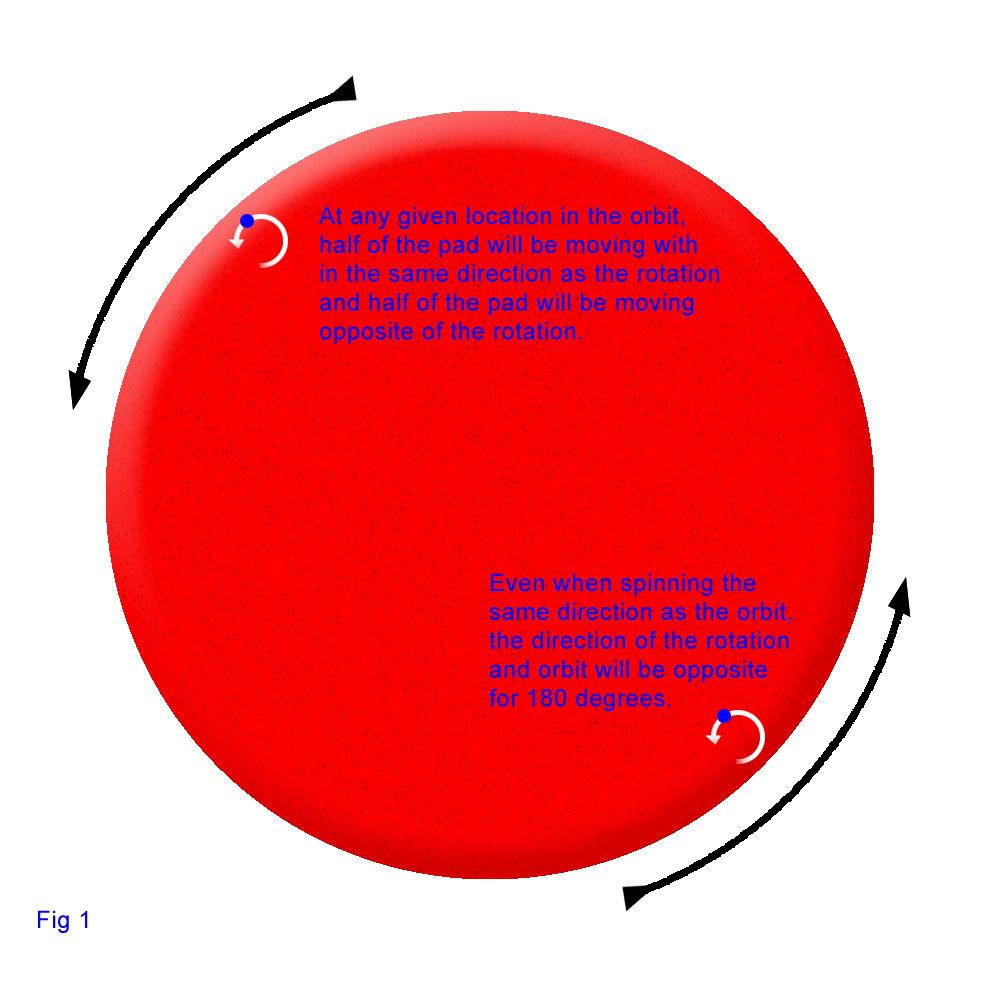

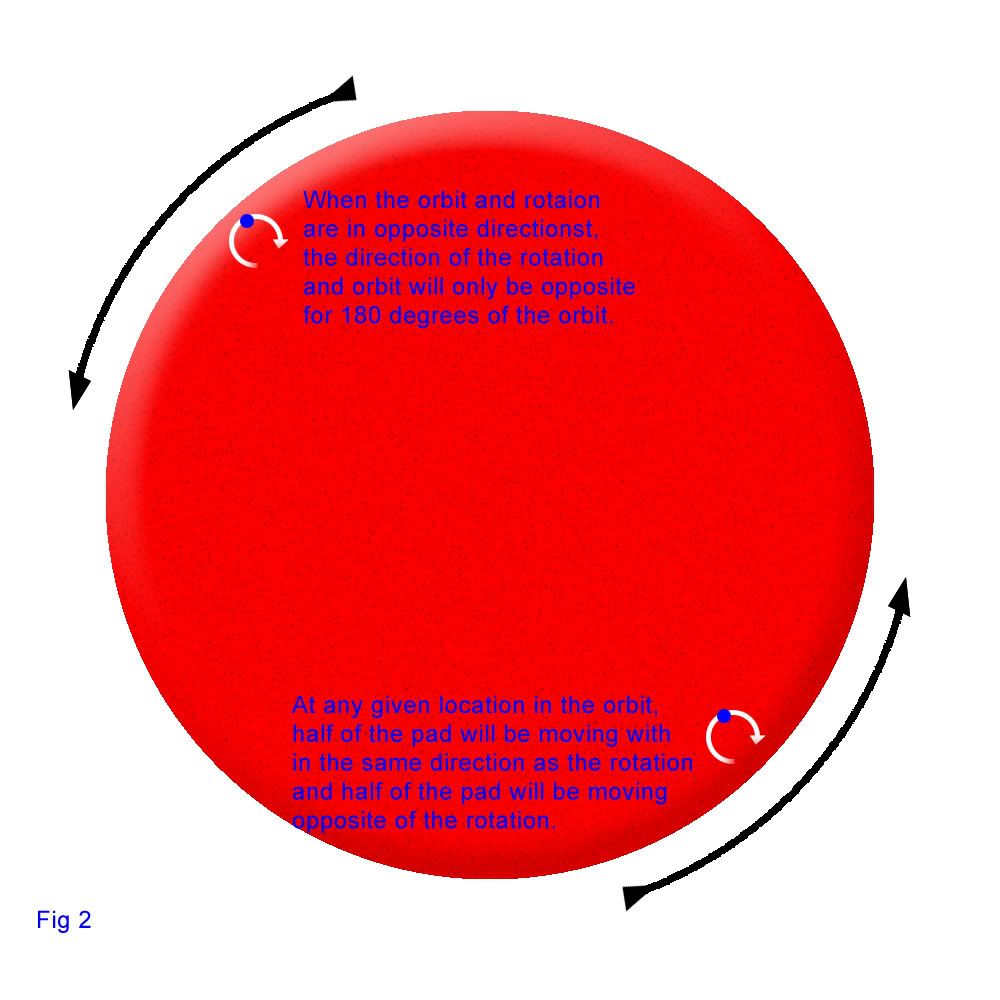

The direction of orbit vs. rotation is really a non-factor when it comes to corrective ability because we are dealing with objects that are moving in 360 degree motions. Even if the orbit and rotation are the same direction (counter clockwise for example) the orbit and rotation will still spin against each other for 180 degrees, depending on which part of the pad you are looking at.

Figure one shows a DA machine which the orbit and revolution are the same direction. Yet at the same point in the orbit (roughly 270 degrees) half of the pad is accelerating with the orbit BUT the opposite corner is moving against the orbit.

Fig two shows a DA machine in which the direction of the orbits and revolutions are opposite. Because we are dealing with 360 degrees of movement, once again we have half of the pad accelerating in the same direction of the pad and half the pad moving against the rotation.

The net effect on the total movement between the paint and the pad is ZERO. If we are measuring the total area the pad is moving (per a given time) across the paint, we will find that machines will similar directions will have more acceleration and de-acceleration in a given orbit, but only slight. The total distance covered will be identical. When the orbit and rotation are heading the same direction (on the outer edge) the pad will accelerate to a spot faster, but then will stall quickly and move backwards slightly, before whipping back out on an arc.

When the movements are opposite, the pad will accelerate more gently, but will slow less, make a less dramatic turn (loop) and resume accelerating smoother. The total distance covered will be identical. It is like driving 45 mph, then slowing to 15 mph, then smoothly accelerating back to 45 mph in a given time frame instead of starting at 50 mph, slowing to 5 mph, and accelerating back up to 50 mph in the same time frame.

My second point, in regards to the Flex vs. the Makita is that the Makita will deliver more RPM and OPM, thus has more cutting ability (potential) if the strokes are identical.

The Flex has a maximum RPM of 480, as verified independently. The Flex will always orbit at 10 orbits per RPM, this is easy to test. Simply spin the backing plate one full rotation and count the amount of times the machine orbits (snakes in and out). A small piece of tape may help. You will always get 10 orbits per RPM, and will a maximum of 480 RPM (verified by a strobe light) you are limited to 4800 OPM max. I am not sure how Flex comes up with a number of 9600 OPM, they must count the inside 180 degrees and the outside 180 degrees of each orbit as separate?

By Flex’s apparent rating the PC/Meguiar’s G110v2 would both have orbit ratings of 13,600 (!) and the Makita 2mode would have rating of 11,600 OPM.

So at least when it comes to the ringside numbers the Makita 2mode has an advantage in both RPM potential (670 vs. 480) and OPM (5800 vs. 4800). When they step into the ring and pressure (thus bog) is applied, I am not sure how they pan out. The Flex is able to maintain near maximum RPM (and OPM) with fairly heavy pressure (as verified by a timer and strobe light). I am unsure about the Makita, but on paper it certainly has higher potential.

TH0001 said:

By Flex’s apparent rating the PC/Meguiar’s G110v2 would both have orbit ratings of 13,600 (!) and the Makita 2mode would have rating of 11,600 OPM.

So at least when it comes to the ringside numbers the Makita 2mode has an advantage in both RPM potential (670 vs. 480) and OPM (5800 vs. 4800). When they step into the ring and pressure (thus bog) is applied, I am not sure how they pan out. The Flex is able to maintain near maximum RPM (and OPM) with fairly heavy pressure (as verified by a timer and strobe light). I am unsure about the Makita, but on paper it certainly has higher potential.