coltagious

New member

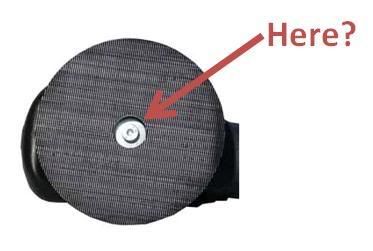

Guys, I have a prob here. On my second usage of the flex, i cranked it up to speed 6 when trying to minimise some watermarks on a horizontal panel. Pressure used is slight, definately not as much as I would use with a PC7424. Suddenly, i saw lots of small particles and smoke coming out between the small area between the metal housing of the flex and the backing plate.

I quickly stopped the flex and checked. I realised that the felt ring had been burned into the backing plate. Anyone had the same prob? What have i done wrong?

I quickly stopped the flex and checked. I realised that the felt ring had been burned into the backing plate. Anyone had the same prob? What have i done wrong?