KenAllwine

New member

I had a customer call me back in June about bringing in an MG for me to freshen up for a sale he wanted to take it to. Now, we all know the iconic MG and it's British Racing Green motif. Those wonderful rubber front bumpers and that wonderful convertible top and the quality of the seats.... So, I had a certain expectation of what I was going to be working on.

I couldn't have been more wrong! What arrived was a 1968 MGC GT with only 30,000 original miles. I had to take a "double-take" on this car. When he pulled in I saw this cool little ride.

I just had to do a bit of research on this (my inner car nerd was prevailing). I come to find out that this is a rather rare vehicle. Between 1967 and 1969, only 9,002 vehicle were built for global consumption. What was interesting as this has an Austin-Healey straight 6 engine. With this arrangement, they had to bump out the hood to fit the air cleaners. Unfortunately, this cool little hatchback didn't do as well as MG Hoped and production ended in 1969.

Now, back to the matter at hand. Once my customer arrived and I finished admiring the car, we got down to business. After talking with the customer and doing a walk around, it was evident that parts of the the car were repainted. He also pointed out some places where there was paint that he would like removed from the painter's oversight in some areas.

With the the inspection done and poor weather setting in, it was time to get the car into the studio. As I do most of my work during evenings and weekends, starting this project would have to wait until the next evening.

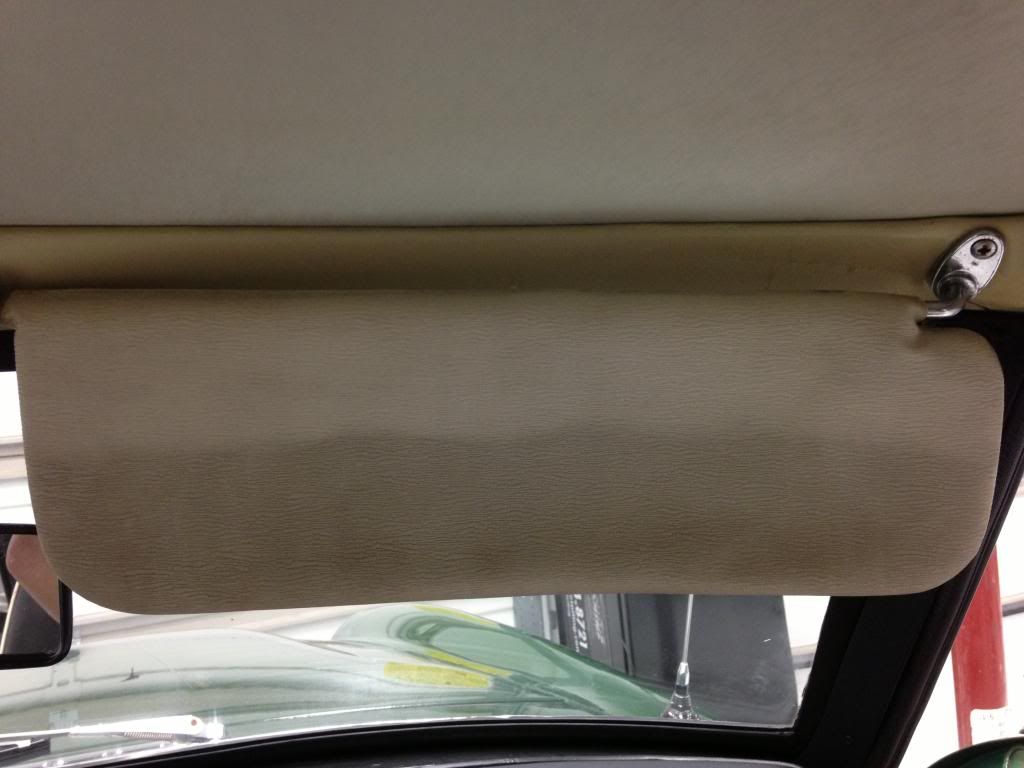

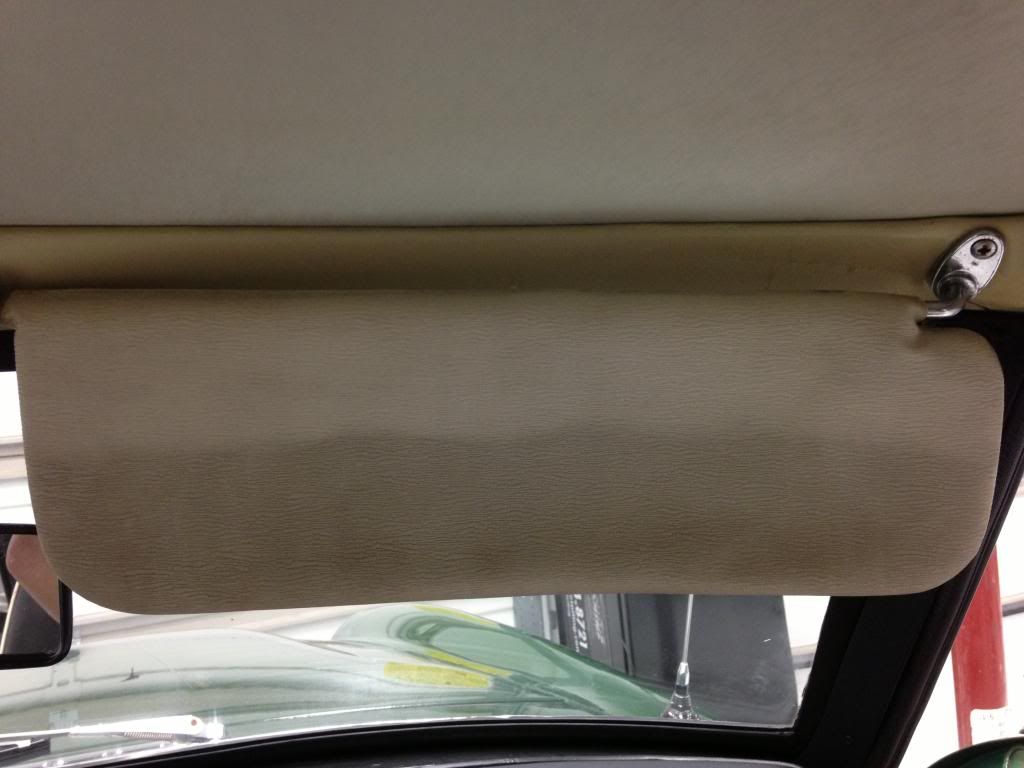

To get started with this project, I tackled the interior first. Overall, for the vehicle's age, it was in quite good condition. A bit of surface dirt but no heavy staining. Using 10:1 APC, I went about cleaning the dash, door panels and the other hard surfaces. For the carpeted surfaces, I used my VX5000 steamer with a few light mists of APC worked in.

Were I ended up spending more time than expected was cleaning the white piping around the front and rear seats. Again using 10:1 APC, I used a toothbrush to clean the piping. I gently pulled back on the piping to clean all the way down to the stitching.

Next, I turned to the engine. The engine as with the interior was only lightly dirty. Using ONR, I cleaned up all the dirty spots and surface dust. I also cleaned up the chrome bits using Chemical Guys Metal Shine.

Before:

After:

Then it was at time to move onto the paint. The customer wasn't looking for ultimate perfection in the paint but rather an improvement. This was actually and ideal situation to use Sonax Pefect Finish. It provides a light amount of cut and some hiding ability. Using LC blue pads in various sizes and a Rupes 21 and a Griots D/A, I went to work on the finish. This is where I quickly learned that the repaint was a single stage finish. I paused my polishing efforts to add additional tape to edges and high points.

Video if it works:

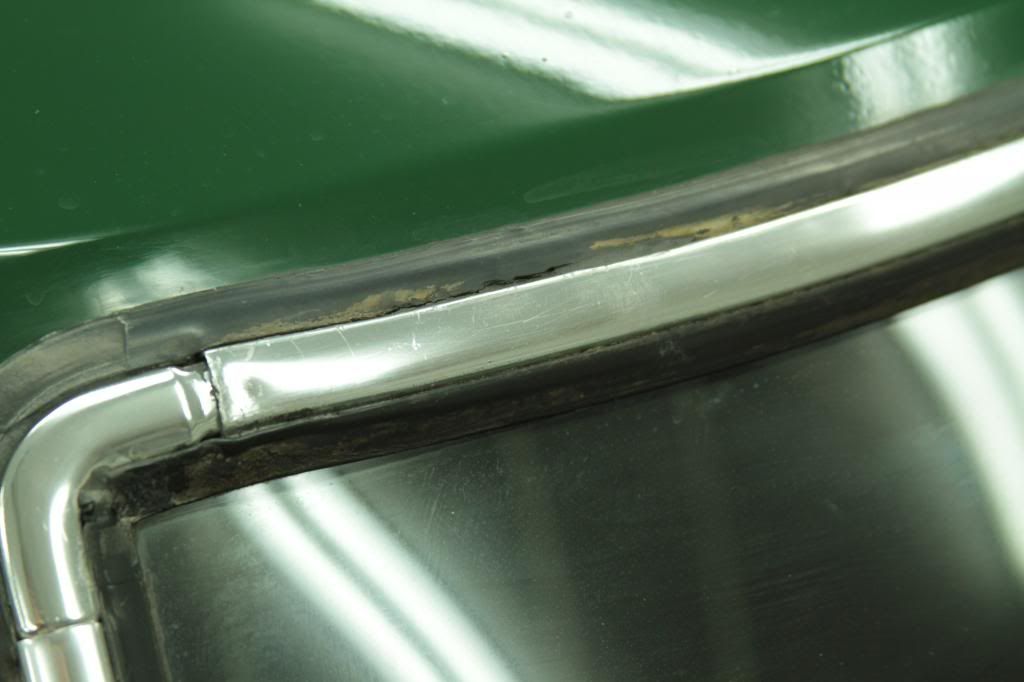

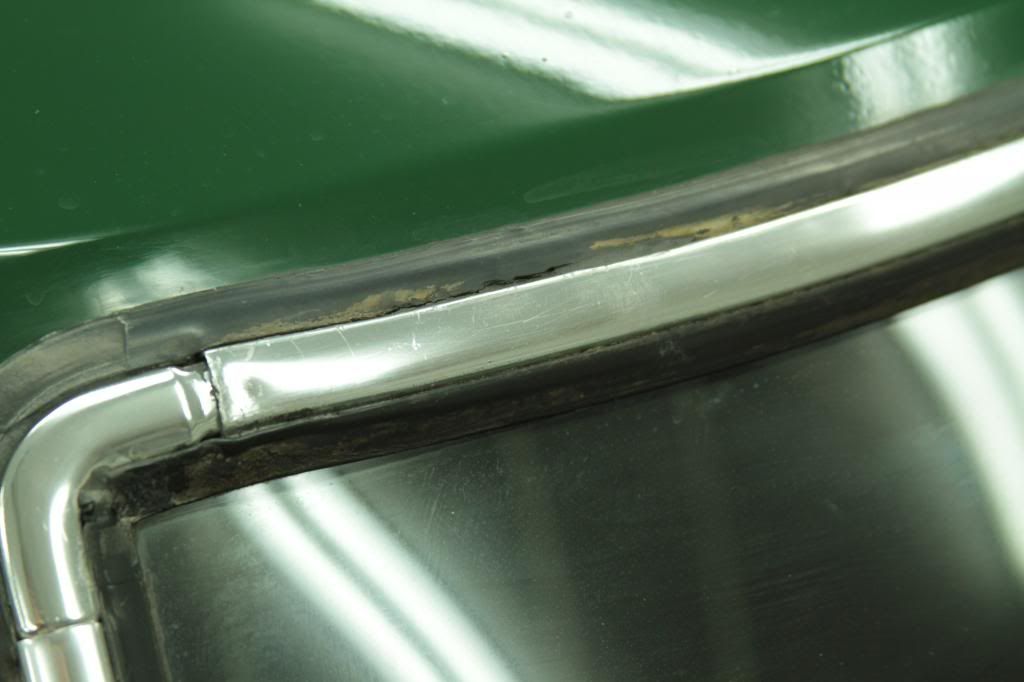

Next on the list was the handling of the overspray on the door strikers, bright work and windows. Being that this was single stage paint and to the suggestion of others on the boards here, I used lacquer thinner and cotton swabs to remove paint for where it shouldn't be.

Overspray on windows

The last bit to handle was the wheels. The chrome knock offs had a good bid of corrosion and spent a good amount of time hand polishing the chrome. Because this was my first car with true knock offs, I decided it was best to lift the vehicle off the ground and clean the wheels with them still on the car. I did not want to risk damaging the chrome finish of the center knock off bolts. Finishing them off I applied Meguiars Hyper Shine to the tires.

All done, I brought it out in to the sun for final inspection and pictures.

The project took a total of 18 hours to complete over 4 evenings. Which I was about to learn a business lesson first hand...

The customer was very please with the results. However, I thought he was going to have a heart attack when I handed him the invoice. Needless to say he was shocked. We had a bit of a discussion and unfortunately, did not we did not have the same expectations for the vehicle.

This is where I learned a very valuable business lesson. You should never forget to discuss price before the customer leaves (unless they don't care). I was used to working on direct customer vehicles (retail business model) and having relatively set prices for services. This customer was flipping this car and does quite a few per year (wholesale) as I learned in our discussions after he paid the bill. He was expecting a much lower price as to not impact his bottom line. He gave me a second car to work on at the time of pick up on the MGC. However, I believe I may have chased him off with the price of this project. Being early in my business this was a rough mistake to make. Lesson learned...

I will share my experience on the second car in a future write up (1984 Black Porsche Targa).

I couldn't have been more wrong! What arrived was a 1968 MGC GT with only 30,000 original miles. I had to take a "double-take" on this car. When he pulled in I saw this cool little ride.

I just had to do a bit of research on this (my inner car nerd was prevailing). I come to find out that this is a rather rare vehicle. Between 1967 and 1969, only 9,002 vehicle were built for global consumption. What was interesting as this has an Austin-Healey straight 6 engine. With this arrangement, they had to bump out the hood to fit the air cleaners. Unfortunately, this cool little hatchback didn't do as well as MG Hoped and production ended in 1969.

Now, back to the matter at hand. Once my customer arrived and I finished admiring the car, we got down to business. After talking with the customer and doing a walk around, it was evident that parts of the the car were repainted. He also pointed out some places where there was paint that he would like removed from the painter's oversight in some areas.

With the the inspection done and poor weather setting in, it was time to get the car into the studio. As I do most of my work during evenings and weekends, starting this project would have to wait until the next evening.

To get started with this project, I tackled the interior first. Overall, for the vehicle's age, it was in quite good condition. A bit of surface dirt but no heavy staining. Using 10:1 APC, I went about cleaning the dash, door panels and the other hard surfaces. For the carpeted surfaces, I used my VX5000 steamer with a few light mists of APC worked in.

Were I ended up spending more time than expected was cleaning the white piping around the front and rear seats. Again using 10:1 APC, I used a toothbrush to clean the piping. I gently pulled back on the piping to clean all the way down to the stitching.

Next, I turned to the engine. The engine as with the interior was only lightly dirty. Using ONR, I cleaned up all the dirty spots and surface dust. I also cleaned up the chrome bits using Chemical Guys Metal Shine.

Before:

After:

Then it was at time to move onto the paint. The customer wasn't looking for ultimate perfection in the paint but rather an improvement. This was actually and ideal situation to use Sonax Pefect Finish. It provides a light amount of cut and some hiding ability. Using LC blue pads in various sizes and a Rupes 21 and a Griots D/A, I went to work on the finish. This is where I quickly learned that the repaint was a single stage finish. I paused my polishing efforts to add additional tape to edges and high points.

Video if it works:

Next on the list was the handling of the overspray on the door strikers, bright work and windows. Being that this was single stage paint and to the suggestion of others on the boards here, I used lacquer thinner and cotton swabs to remove paint for where it shouldn't be.

Overspray on windows

The last bit to handle was the wheels. The chrome knock offs had a good bid of corrosion and spent a good amount of time hand polishing the chrome. Because this was my first car with true knock offs, I decided it was best to lift the vehicle off the ground and clean the wheels with them still on the car. I did not want to risk damaging the chrome finish of the center knock off bolts. Finishing them off I applied Meguiars Hyper Shine to the tires.

All done, I brought it out in to the sun for final inspection and pictures.

The project took a total of 18 hours to complete over 4 evenings. Which I was about to learn a business lesson first hand...

The customer was very please with the results. However, I thought he was going to have a heart attack when I handed him the invoice. Needless to say he was shocked. We had a bit of a discussion and unfortunately, did not we did not have the same expectations for the vehicle.

This is where I learned a very valuable business lesson. You should never forget to discuss price before the customer leaves (unless they don't care). I was used to working on direct customer vehicles (retail business model) and having relatively set prices for services. This customer was flipping this car and does quite a few per year (wholesale) as I learned in our discussions after he paid the bill. He was expecting a much lower price as to not impact his bottom line. He gave me a second car to work on at the time of pick up on the MGC. However, I believe I may have chased him off with the price of this project. Being early in my business this was a rough mistake to make. Lesson learned...

I will share my experience on the second car in a future write up (1984 Black Porsche Targa).