Alex Boyce

New member

I was contacted by this client due to his interest in 22PLE, and after some discussion of services needed/desired, a date was set. I knew I wouldn't be able to complete both cars in one day and I would need some help. I had previously talked with Charlie Hahn about "teaming up" for a detail when the opportunity arose, and this detail taking place in the Detroit area was the perfect opportunity.

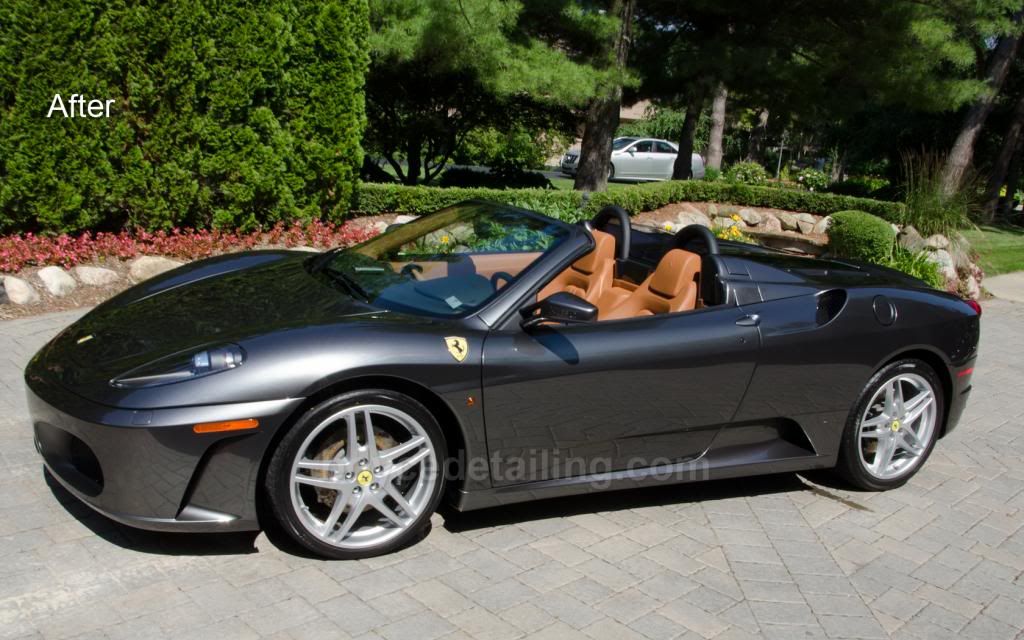

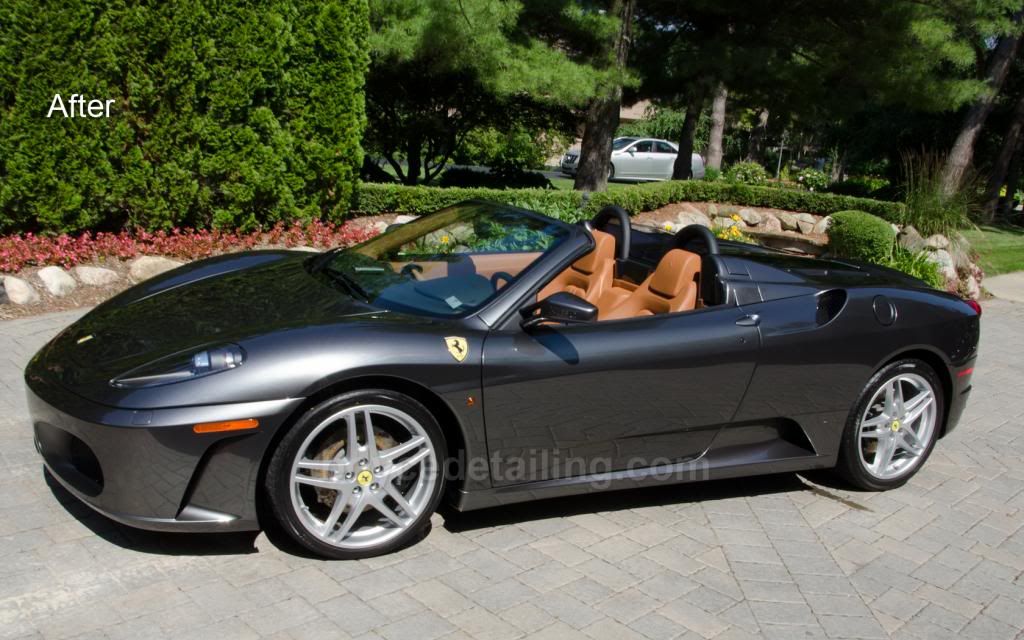

Charlie and I arrived early in the morning to meet with the customer and evaluate the finishes of the vehicles, which had both been detailed a year prior by Todd Cooperider at his facility in Ohio. The Ferrari was still in outstanding condition; there was some light marring here and there, but nothing serious. The Mercedes on the other hand was a daily driver, and saw the automatic car wash often... and it showed. The owner made the day even better, a great person with a great appreciation for the work required to maintain his cars properly.

Process for Ferrari F430:

- 1Z ColourTec for wheels

- OPC for tires

- Foamed with Meguiar's Hyper Wash/OPC mix

- Exhaust cleaned with P21S TAW and various brushes

- Dried with leaf blower and WW towels

- Muffler polished with Optimum metal polish/black foam via Rupes LHR75

- HD Polish on black foam to remove any marring/haze via Rupes LHR21ES and LHR75

- Paintwork was wiped down with CarPro Eraser

- 22PLE VX1 Pro applied to all paintwork

- 22PLE VM1 applied to wheel faces/exhaust tips

- Full interior detail, including leather cleaning and conditioning with Ferrari factory-sourced products

- Opti-glass Pro applied to windshield

- HD Fabric Protector applied to convertible top

- Engine cleaned with steamer/HD Touch

- Tires and wheel wells dressed with Garry Dean's Infinite Performance Tire and Trim Gel

Process for Mercedes-Benz SL55 AMG:

- 1Z ColourTec for wheels

- OPC for tires

- Foamed with Meguiar's Hyper Wash/OPC mix

- Exhaust cleaned with P21S TAW and various brushes

- Dried with leaf blower and WW towels

- Polished with Meguiar's D300/Rupes Yellow polishing pad, via Rupes LHR21ES and Rupes LHR75

- Car wiped down with CarPro Eraser

- 22PLE VX1 applied to all paintwork

- 22PLE VM1 applied to exhaust tips

- Opti-Glass Pro applied to windshield

- Tires dressed with CG VRP

- Wheel wells dressed with Garry Dean's Infinite Performance Tire and Trim Gel

- Interior vacuumed/wiped down with Garry Dean's IUDJ

- Engine detailed with OPC and steam

Due to time only after shots were taken of the Mercedes, but here are pictures of both, starting with the Ferrari:

Mercedes:

Thanks for looking!

Charlie and I arrived early in the morning to meet with the customer and evaluate the finishes of the vehicles, which had both been detailed a year prior by Todd Cooperider at his facility in Ohio. The Ferrari was still in outstanding condition; there was some light marring here and there, but nothing serious. The Mercedes on the other hand was a daily driver, and saw the automatic car wash often... and it showed. The owner made the day even better, a great person with a great appreciation for the work required to maintain his cars properly.

Process for Ferrari F430:

- 1Z ColourTec for wheels

- OPC for tires

- Foamed with Meguiar's Hyper Wash/OPC mix

- Exhaust cleaned with P21S TAW and various brushes

- Dried with leaf blower and WW towels

- Muffler polished with Optimum metal polish/black foam via Rupes LHR75

- HD Polish on black foam to remove any marring/haze via Rupes LHR21ES and LHR75

- Paintwork was wiped down with CarPro Eraser

- 22PLE VX1 Pro applied to all paintwork

- 22PLE VM1 applied to wheel faces/exhaust tips

- Full interior detail, including leather cleaning and conditioning with Ferrari factory-sourced products

- Opti-glass Pro applied to windshield

- HD Fabric Protector applied to convertible top

- Engine cleaned with steamer/HD Touch

- Tires and wheel wells dressed with Garry Dean's Infinite Performance Tire and Trim Gel

Process for Mercedes-Benz SL55 AMG:

- 1Z ColourTec for wheels

- OPC for tires

- Foamed with Meguiar's Hyper Wash/OPC mix

- Exhaust cleaned with P21S TAW and various brushes

- Dried with leaf blower and WW towels

- Polished with Meguiar's D300/Rupes Yellow polishing pad, via Rupes LHR21ES and Rupes LHR75

- Car wiped down with CarPro Eraser

- 22PLE VX1 applied to all paintwork

- 22PLE VM1 applied to exhaust tips

- Opti-Glass Pro applied to windshield

- Tires dressed with CG VRP

- Wheel wells dressed with Garry Dean's Infinite Performance Tire and Trim Gel

- Interior vacuumed/wiped down with Garry Dean's IUDJ

- Engine detailed with OPC and steam

Due to time only after shots were taken of the Mercedes, but here are pictures of both, starting with the Ferrari:

Mercedes:

Thanks for looking!