Greg Nichols

New member

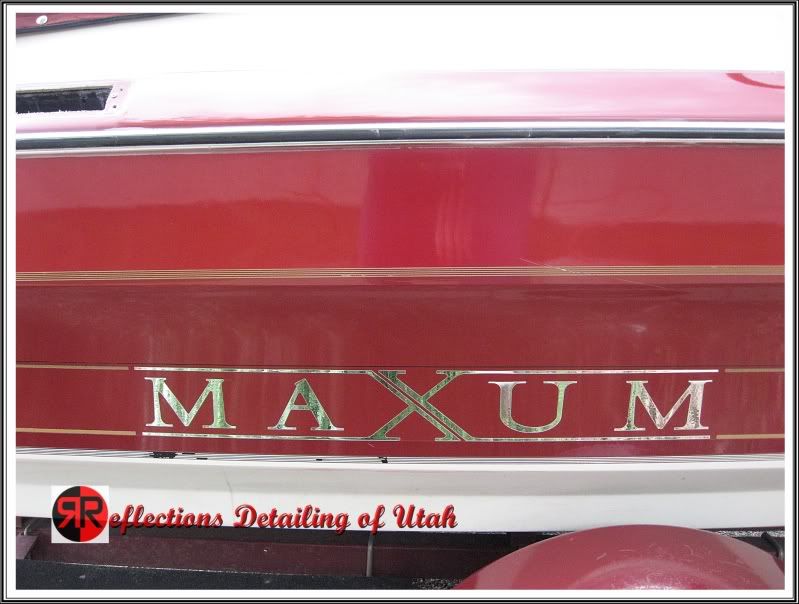

Okay gang! I've have become behind in my posting of work, been busy. Here is a boat I'm presently working on right now. The client wanted it in sellable shape, nothing like a mirror finish, a one hit polishing jobber. I had a little time on my hands with this so I did some testing.

I tested SurBuf pads, PC correction on a gel coat, and my patience. I also messed around with some different polishes. I still find 105 to be my friend for boats.

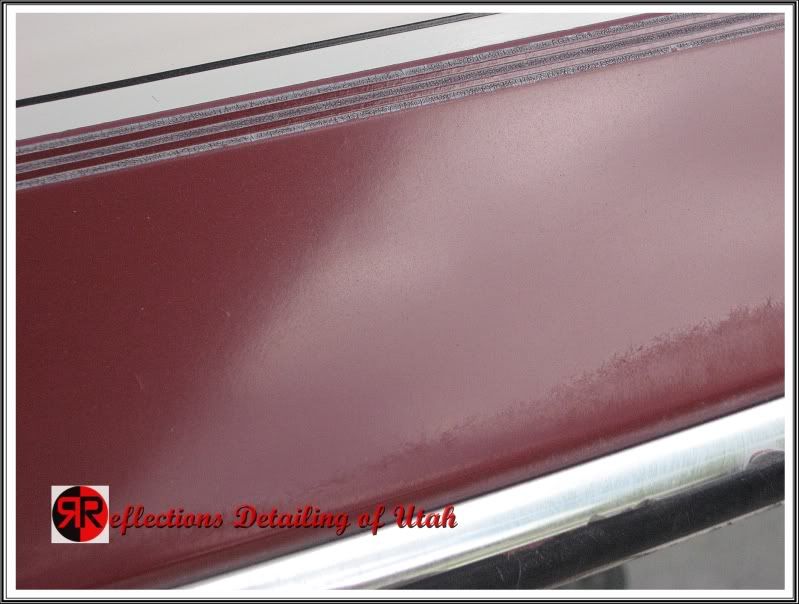

Here is the boat before: it wasn't chalky but headed in that direction, so I felt there is some hope of correction. When they get this bad, clients need to know that there is a good chance it will start fading faster than if they had just kept up on it. Boat gel coats are porous, and UV breaks them down fast. YEARLY maintenance is a MUST!

I did some test spots to see if the SurBuf or wool would be used. I decided to go with the SurBuf even though it was not as fast as the wool/rotary combo. I was using my KBM with both.

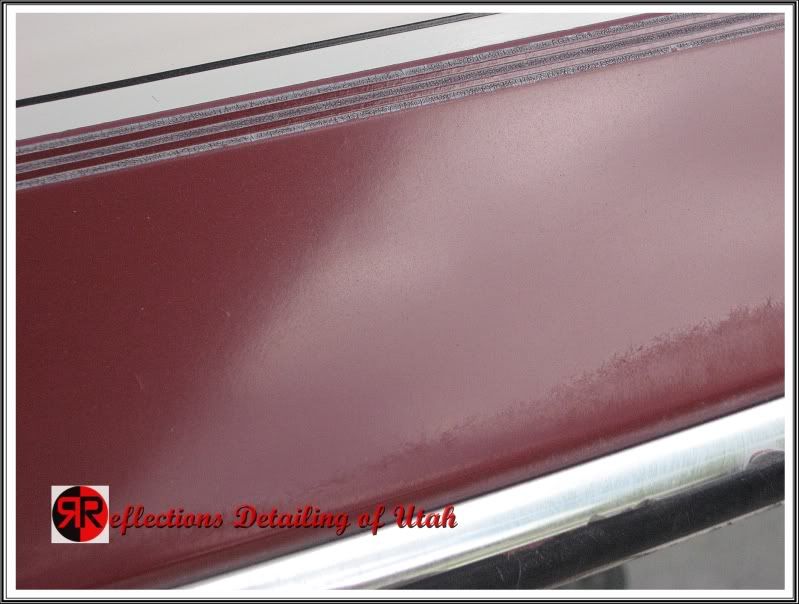

Pretty good clarity:

Same spot, but I wet sanded with 1500 and then re-polished, you can see the clarity even in this photo, but wow a huge diff in person.

Its coming along, and I'm getting a feel of this SurBuf and gel coat.

Okay, I decided to use a yellow 2.0 megs pad and 105 in an area to see how much correction I could get with that combo. I have used 105 the whole time too.

Now take a look at the SurBuf and 105. Both areas were not touched before hand, so this is diff. I have run across many threads saying they corrected the boat using only a PC and foam. the color dramatically improved, but the clarity is the difference. I also believe the gel coat is still oxidized and will fade in short order. Imagine what multi steps with sanding would do?!

The other side of the boat I switched back to my wool and rotary, why? Its faster, how much...took me about 1.5 hours less to do this other side to the same standard as the PC/SurBuf, this is minus the experimental processes. I think the PC/SurBuf on a boat is good, but not for heavy oxidation removals. The pads also take a huge beating, and need to be washed a lot. I can use one wool pad to three SurBufs.

While the clairty is greatly improved, its still has some marring (pad) left behind, but this is suppose to be a one hit polishing.

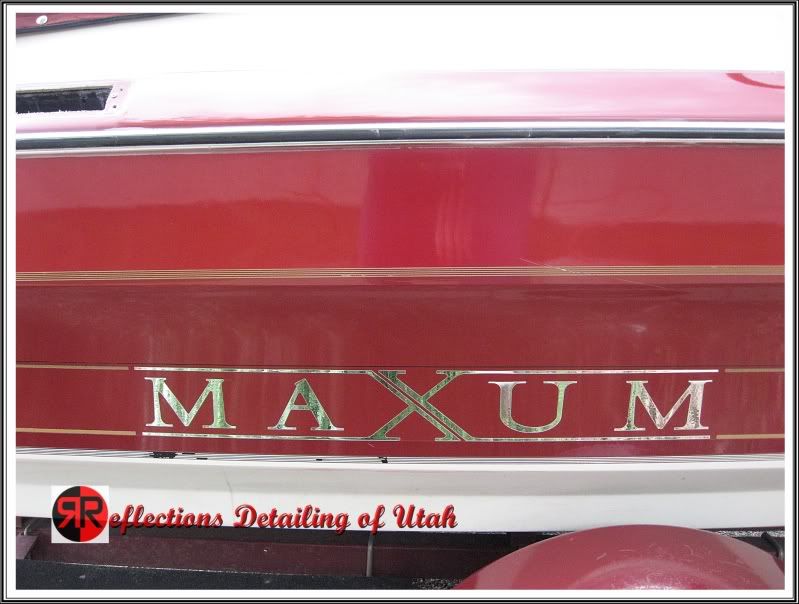

Just in case you forgot what the boat looked like:

Here is a summary:

I love SufBuf pads and they do a great job, but for serious corrective work on a boat......nothing beats wool and a rotary.

You can improve a boats appearance with a PC/foam but clarity is a stretch with oxidation.

I tired Meg 49 again, and it seemed to work great, but after a wash all the oils ran out showing areas I didn't work as well as others. With 105 I didn't have this problem. Yes I need to "feed" the gel coat, but why gum up a pad and get false results in the cutting stage? I will go over the whole boat with a PC/foam and feed oils back later, it will be faster then trying to do it all at once.

Boat are tough on your body, you need to charge accordingly, the time commitment is large. You use up wool pads, go through a lot of product, have tons of color transfer to pads.....charge properly don't sell your self short.

Cheers,

GREG

I tested SurBuf pads, PC correction on a gel coat, and my patience. I also messed around with some different polishes. I still find 105 to be my friend for boats.

Here is the boat before: it wasn't chalky but headed in that direction, so I felt there is some hope of correction. When they get this bad, clients need to know that there is a good chance it will start fading faster than if they had just kept up on it. Boat gel coats are porous, and UV breaks them down fast. YEARLY maintenance is a MUST!

I did some test spots to see if the SurBuf or wool would be used. I decided to go with the SurBuf even though it was not as fast as the wool/rotary combo. I was using my KBM with both.

Pretty good clarity:

Same spot, but I wet sanded with 1500 and then re-polished, you can see the clarity even in this photo, but wow a huge diff in person.

Its coming along, and I'm getting a feel of this SurBuf and gel coat.

Okay, I decided to use a yellow 2.0 megs pad and 105 in an area to see how much correction I could get with that combo. I have used 105 the whole time too.

Now take a look at the SurBuf and 105. Both areas were not touched before hand, so this is diff. I have run across many threads saying they corrected the boat using only a PC and foam. the color dramatically improved, but the clarity is the difference. I also believe the gel coat is still oxidized and will fade in short order. Imagine what multi steps with sanding would do?!

The other side of the boat I switched back to my wool and rotary, why? Its faster, how much...took me about 1.5 hours less to do this other side to the same standard as the PC/SurBuf, this is minus the experimental processes. I think the PC/SurBuf on a boat is good, but not for heavy oxidation removals. The pads also take a huge beating, and need to be washed a lot. I can use one wool pad to three SurBufs.

While the clairty is greatly improved, its still has some marring (pad) left behind, but this is suppose to be a one hit polishing.

Just in case you forgot what the boat looked like:

Here is a summary:

I love SufBuf pads and they do a great job, but for serious corrective work on a boat......nothing beats wool and a rotary.

You can improve a boats appearance with a PC/foam but clarity is a stretch with oxidation.

I tired Meg 49 again, and it seemed to work great, but after a wash all the oils ran out showing areas I didn't work as well as others. With 105 I didn't have this problem. Yes I need to "feed" the gel coat, but why gum up a pad and get false results in the cutting stage? I will go over the whole boat with a PC/foam and feed oils back later, it will be faster then trying to do it all at once.

Boat are tough on your body, you need to charge accordingly, the time commitment is large. You use up wool pads, go through a lot of product, have tons of color transfer to pads.....charge properly don't sell your self short.

Cheers,

GREG