imported_Dave KG

New member

The car is owned by an elderly couple who wanted their car to "shine again", so a paintwork correction and protection detail was carried out. This detail was carried out in three "shifts" by Bryan and myself: pre-correction prep; correction; protection.

Dropped off with us late afternoon on Monday, Bryan set to work preparing the car for the polishing process: wash (wheels, arches, bodywork...), and clay.

At 8pm, it was time for my "shift" - the machine polishing! Those who know me well know I'm a bit of a night owl, so a night shift of machine polishing is not unknown A 50/50 on the roof of the car certainly showed why the car was lacking in shine, and what was going to be possible:

A 50/50 on the roof of the car certainly showed why the car was lacking in shine, and what was going to be possible:

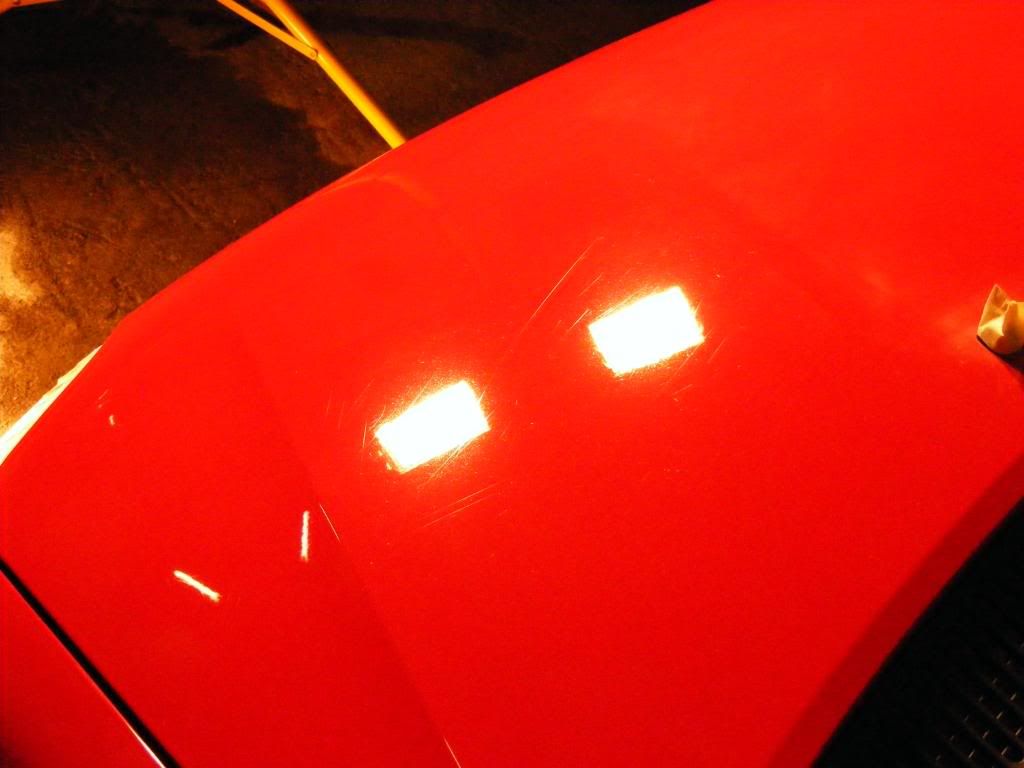

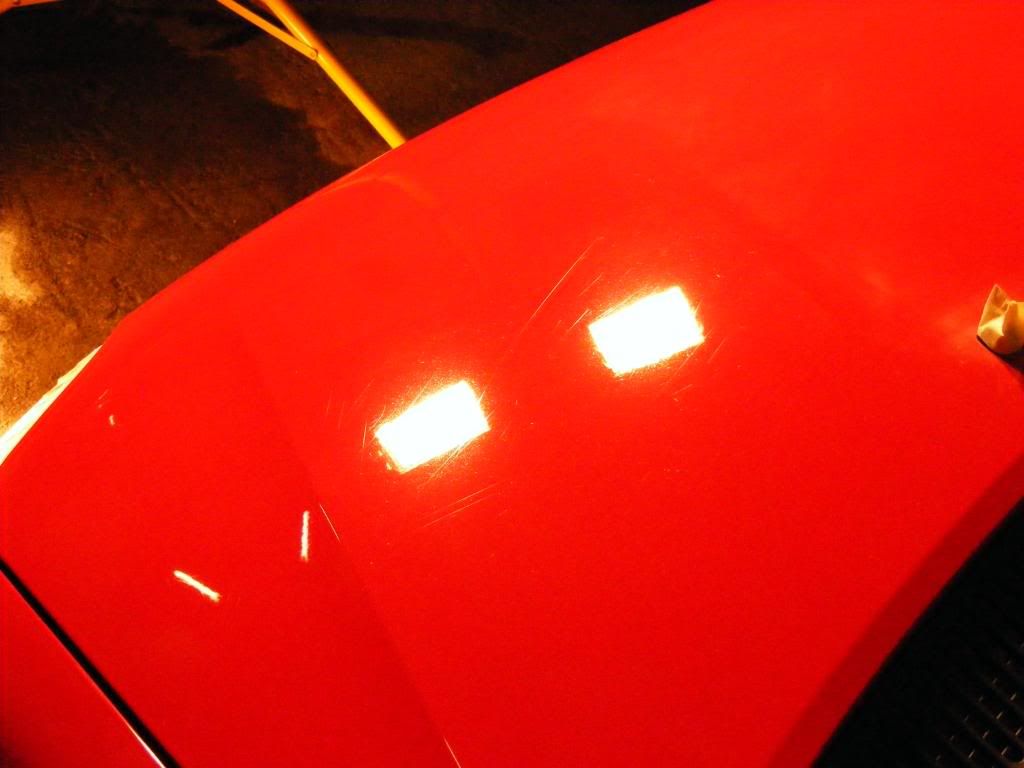

I kicked off on the bonnet as a test section.. light fading here, some nasty swirls and a lot of deeper scratches to contend with:

My trial here was Menzerna PO85RD3.02 Intensive Polish, worked at 1800rpm until clear using the Makita rotary and a Meguiars W8006 polishing pad. Work area of around 1' square. This delivered a vast improvement but for me at this stage, the sheer amount of RDS left was too much:

More was needed, and after a check of the paint thicknesses and the removal rates, I decided to go with 3M Fast Cut Plus on a Meguiars W7006 Cutting Pad. Worked at 2000 - 2500rpm until defects removed. A little drop of Ultrafina SE (the only use I have for this, as I find it bettered by other products in every other aspect) was used to help keep temps lower and working time up. Refinement of the finish was done using Menzerna PO106FA Final Finish, the heavier cutting of the two finishing polishes to give a little more softening of any remaining RDS (very few). Clarity of finish was, on this paint, a match for 85RD.

Results of the more aggressive correction technique and refining:

Much better. As the car's condition was consistent, this was going to be the chosen technique for correction - two stage of Fast Cut to correct, 106FA Final Finish to refine. So, on with the heaters and I settled in for a night of polishing!

The passenger's driver's side before:

As a quick aside to the detail, a very important lesson here in the use of light sources for examining the finish... How good does the finish look in the picture below?

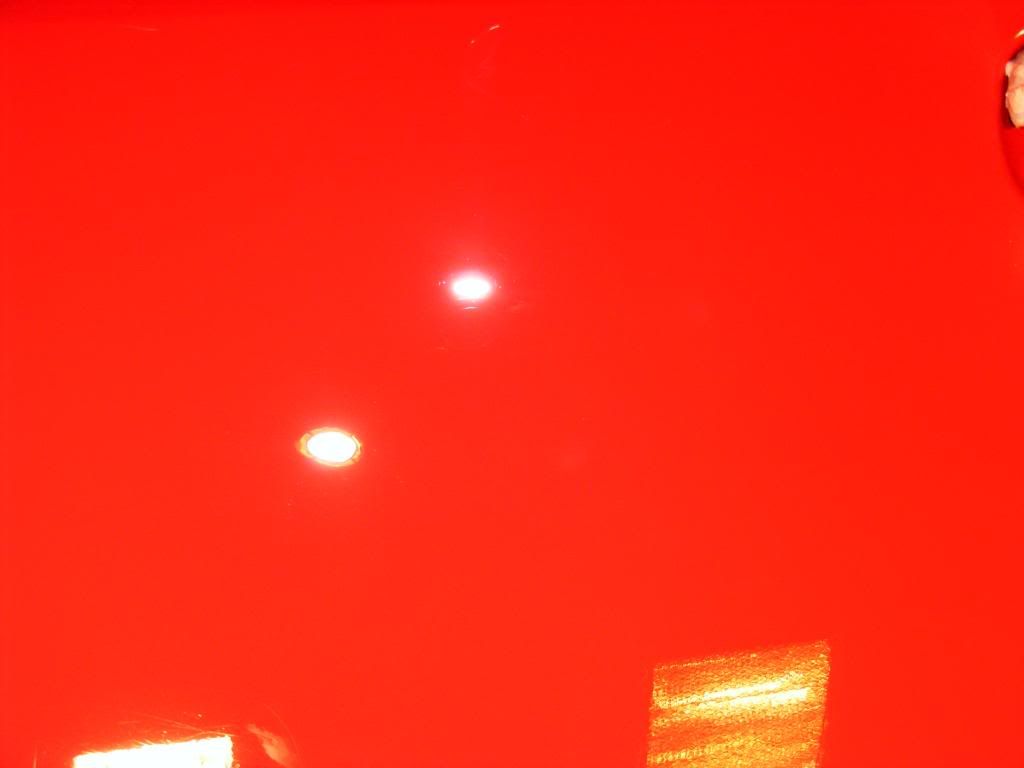

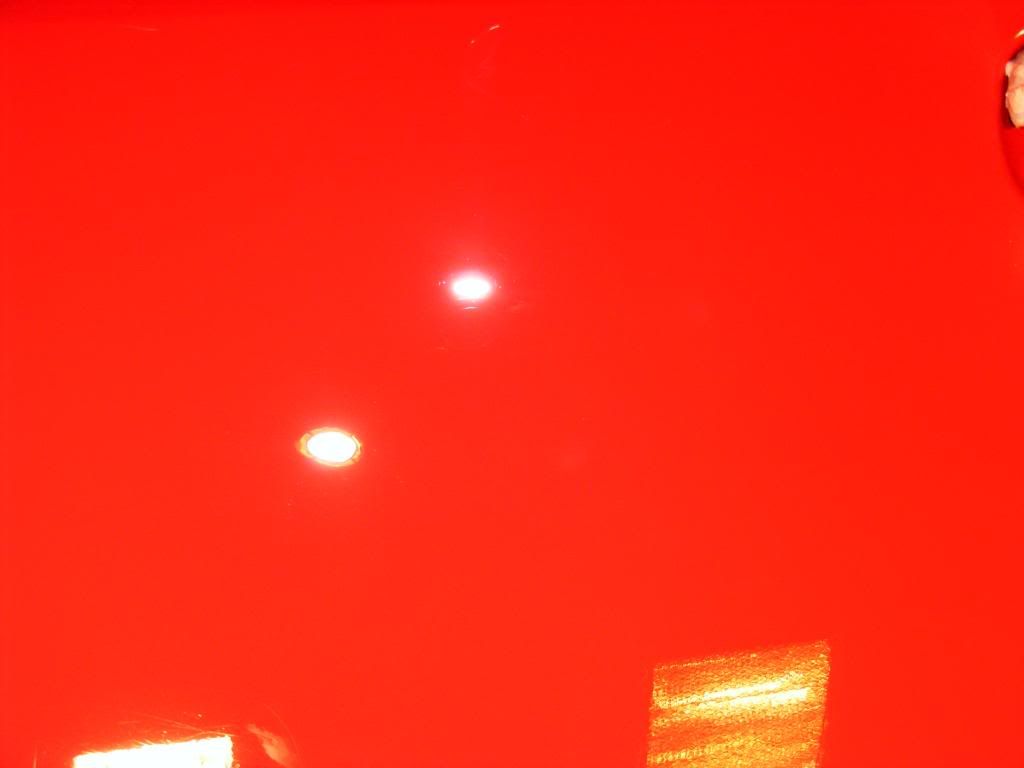

Pretty damn good I'd say under the 500W halogens. Here's the truth of that finish...

This is the finish (in both pics) after the Fast Cut stage and you can see clear hologramming in the latter of the two, an important demonstration of how wrong use of light sources, especially 500W halogens, can mask a lot of nasties in a finish. Brinkmann, Sun Gun or similar is in my eyes essential to really assess the finish quality carefully.

Back to the detail, the holograms now sorted out:

Honest! Under the Sun Gun as well, you can now see the finish is how it should be, as you would expect after the refining stage:

Under the Sun Gun as well, you can now see the finish is how it should be, as you would expect after the refining stage:

Clarity... Good I'd say

All corrected, under the styling line may be out of the way but it receives the same care and attention...

Some more afters of the passenger side:

Dropped off with us late afternoon on Monday, Bryan set to work preparing the car for the polishing process: wash (wheels, arches, bodywork...), and clay.

At 8pm, it was time for my "shift" - the machine polishing! Those who know me well know I'm a bit of a night owl, so a night shift of machine polishing is not unknown

I kicked off on the bonnet as a test section.. light fading here, some nasty swirls and a lot of deeper scratches to contend with:

My trial here was Menzerna PO85RD3.02 Intensive Polish, worked at 1800rpm until clear using the Makita rotary and a Meguiars W8006 polishing pad. Work area of around 1' square. This delivered a vast improvement but for me at this stage, the sheer amount of RDS left was too much:

More was needed, and after a check of the paint thicknesses and the removal rates, I decided to go with 3M Fast Cut Plus on a Meguiars W7006 Cutting Pad. Worked at 2000 - 2500rpm until defects removed. A little drop of Ultrafina SE (the only use I have for this, as I find it bettered by other products in every other aspect) was used to help keep temps lower and working time up. Refinement of the finish was done using Menzerna PO106FA Final Finish, the heavier cutting of the two finishing polishes to give a little more softening of any remaining RDS (very few). Clarity of finish was, on this paint, a match for 85RD.

Results of the more aggressive correction technique and refining:

Much better. As the car's condition was consistent, this was going to be the chosen technique for correction - two stage of Fast Cut to correct, 106FA Final Finish to refine. So, on with the heaters and I settled in for a night of polishing!

The passenger's driver's side before:

As a quick aside to the detail, a very important lesson here in the use of light sources for examining the finish... How good does the finish look in the picture below?

Pretty damn good I'd say under the 500W halogens. Here's the truth of that finish...

This is the finish (in both pics) after the Fast Cut stage and you can see clear hologramming in the latter of the two, an important demonstration of how wrong use of light sources, especially 500W halogens, can mask a lot of nasties in a finish. Brinkmann, Sun Gun or similar is in my eyes essential to really assess the finish quality carefully.

Back to the detail, the holograms now sorted out:

Honest!

Clarity... Good I'd say

All corrected, under the styling line may be out of the way but it receives the same care and attention...

Some more afters of the passenger side: