I know how we can be...we want to get 100% correction, or we're unhappy with our work. We also know the potential danger that lurks when you go for that last couple of percent of correction.

Here's a great example of simply going for "better" instead of "perfect".

My neighbor keeps his kayak stored on the ceiling of his garage, and one day the lines came loose and the kayak landed on the hood of his Impala. It dented the hood, and put a tremendous amount of deep scratches in it. He was able to pop out most of the dents, but it left a lot of uneven surfaces, and he figured that there was nothing he could do with the scratches other than have it repaired at a body shop. I took a look at it and said: "let's see if we can make it better".

Some of the scratches were very big and deep, and I knew there would be limited amount of correction that could be done. to make matters worse, there were uneven spots in the finish where it had been dented, which created a serious risk of burning through the high spots if we went too far.

I started the process with 2000 grit wet sanding, then went to M105 on PFW (which did a great job of correction!), then to SIP on LC white, then to UF on 3M blue waffle pad. While I was at it I did a full correction on the entire hood (badly swirled) to blend it all in.

When I was finished, my neighbor was absolutely blown away. This was despite the fact that some of the deep scratches still remained. Depending on the light and the angle, you really had to look hard to see them.

When all was said and done, I thought it turned out to be a prime example of "better" being perfect.

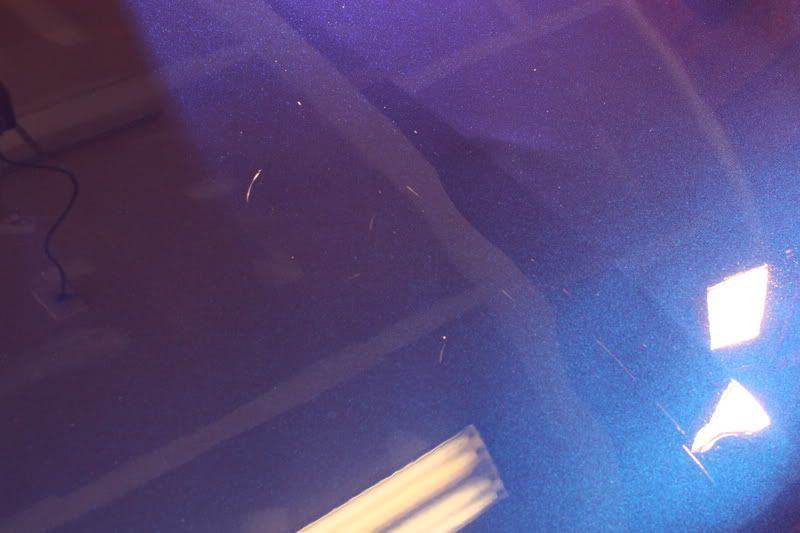

Before:

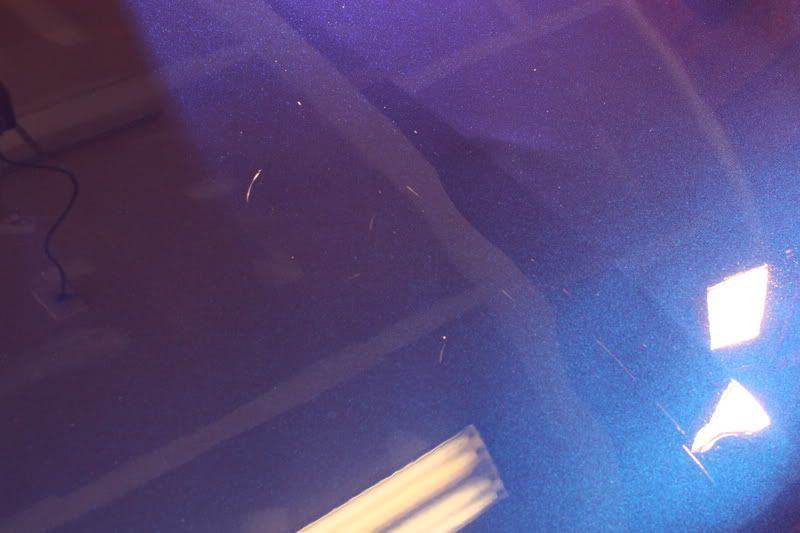

After:

Before:

After:

Here's a great example of simply going for "better" instead of "perfect".

My neighbor keeps his kayak stored on the ceiling of his garage, and one day the lines came loose and the kayak landed on the hood of his Impala. It dented the hood, and put a tremendous amount of deep scratches in it. He was able to pop out most of the dents, but it left a lot of uneven surfaces, and he figured that there was nothing he could do with the scratches other than have it repaired at a body shop. I took a look at it and said: "let's see if we can make it better".

Some of the scratches were very big and deep, and I knew there would be limited amount of correction that could be done. to make matters worse, there were uneven spots in the finish where it had been dented, which created a serious risk of burning through the high spots if we went too far.

I started the process with 2000 grit wet sanding, then went to M105 on PFW (which did a great job of correction!), then to SIP on LC white, then to UF on 3M blue waffle pad. While I was at it I did a full correction on the entire hood (badly swirled) to blend it all in.

When I was finished, my neighbor was absolutely blown away. This was despite the fact that some of the deep scratches still remained. Depending on the light and the angle, you really had to look hard to see them.

When all was said and done, I thought it turned out to be a prime example of "better" being perfect.

Before:

After:

Before:

After: