imported_Dave KG

New member

Today was the first of the Rotary Polishing training days of 2009 ("Beginners"), a day for folks to learn or enhance their rotary polishing skills by examining machine control and polish behaviour on various paints and their own cars.

First off, the "class photo"! :thumb:

The morning was, as always with these training days, spent on the test cars. First focussing on machine control on various panels to get a feeling for the best way to hold and guide the polisher - both on horizontal and vertical panels. The option to try two different "styles" of rotary offered folks the chance to see what suited them best and as expected, some liked the light weight Milwaukee while others preferred the old-school Makita.

Correction techniques were also examined, using a variety of polishes for the general correction, and also for more severe defect correction using compounds. It was the first outing for everyone for the new Menzerna 203S Power Finish which largely impressed those who used it (including me, and while it offers nothing "extra" in terms of cutting or finishing ability to the Menz range it offers an ideal polish for "enhancement" style single stage details where good correction and sharp finshing are required - you can now carry out with one polish what previously took two, but only on certain paints as I found good though 203S was, I could finish Intensive Polish down to match it to the naked eye on all but my softest paint panel).

We also looked at plastics and safe methods for polishing plastics panels by rotary, as well as a demonstration for what happens when plastic gets a bit too hot ... Save to say that you can get metal panels that bit hotter! A good demonstration of the extra care required.

... Save to say that you can get metal panels that bit hotter! A good demonstration of the extra care required.

After a break for lunch to consolidate what the morning session contained, and enjoy sandwiches and choc chip cookies made by Diane, we moved onto the afternoon session which is an open workshop for folks to try what they learned with any product they liked on their own cars

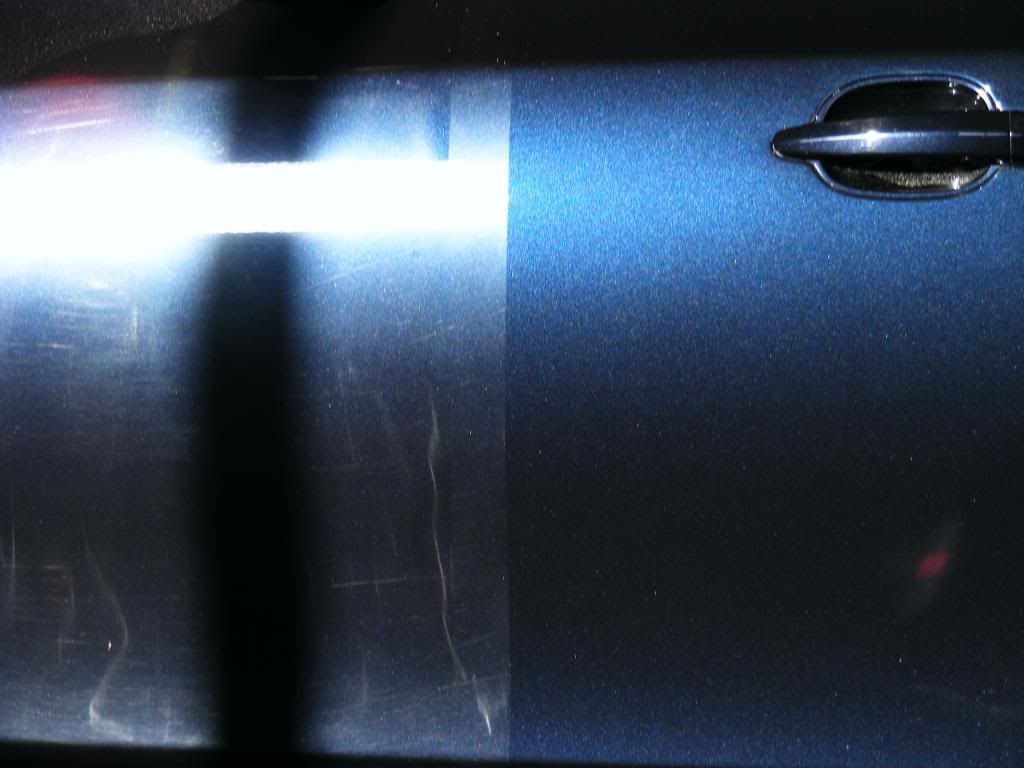

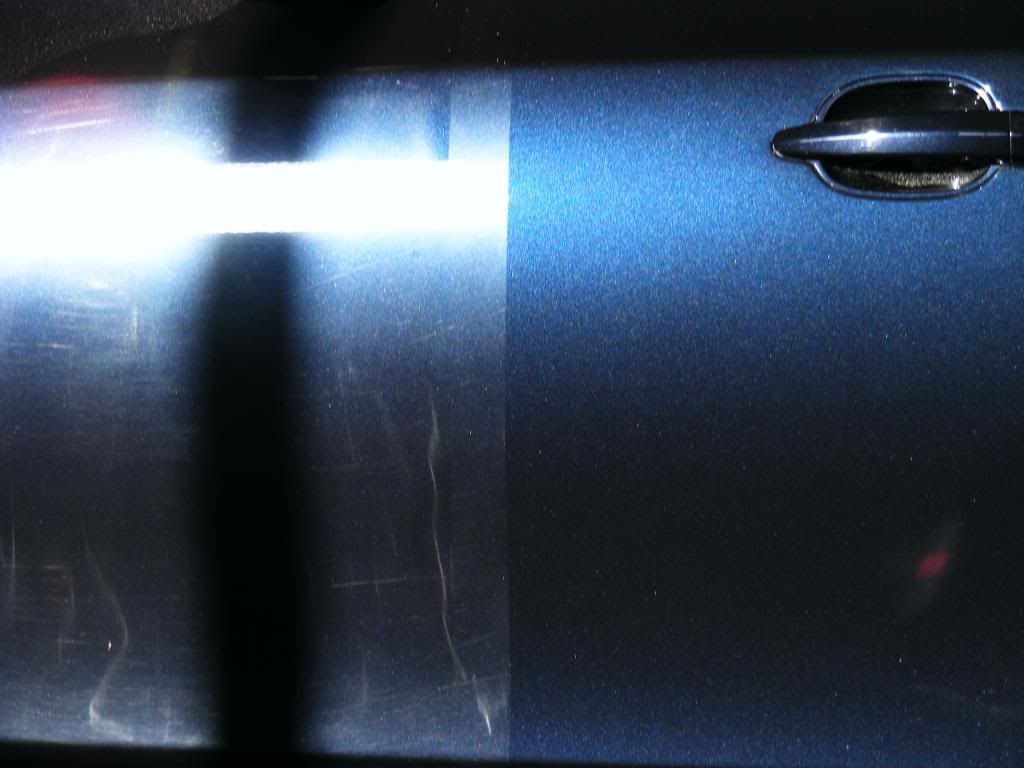

Kicking off with the Mini, and a couple of deeper scratches on the door...

Perfect for practising some localised compounding with a 4" pad,

All gone!

Whole door then polished with 203S, followed with 85RD,

Proud of his mum's work!

The day was too much for some :lol:

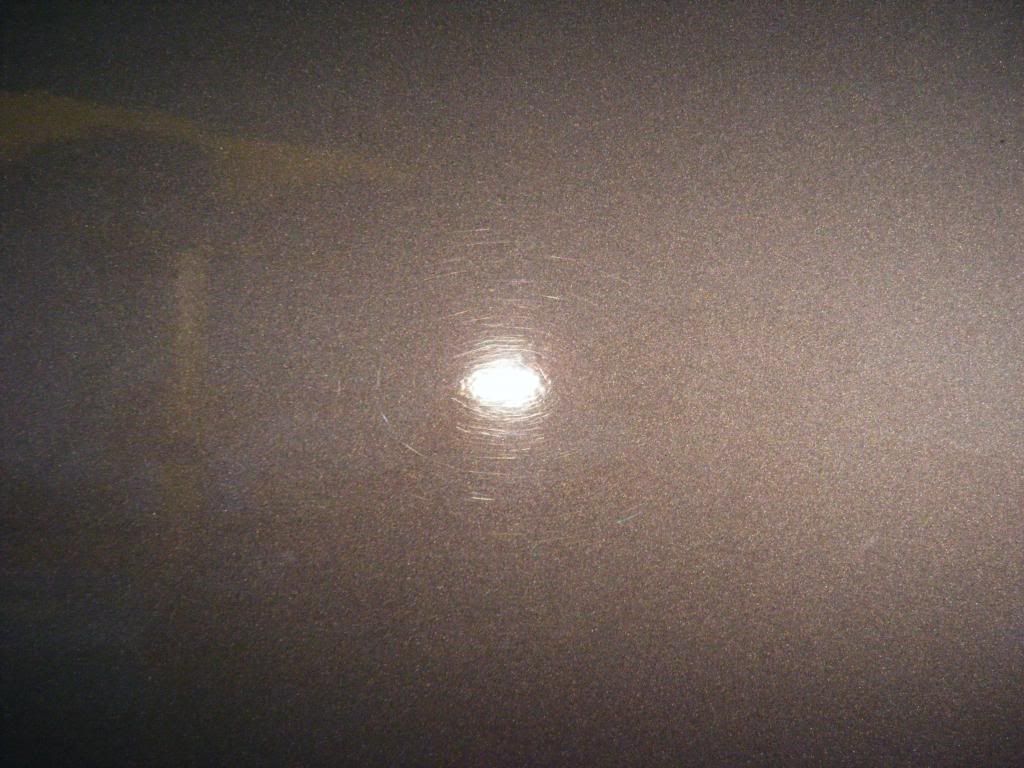

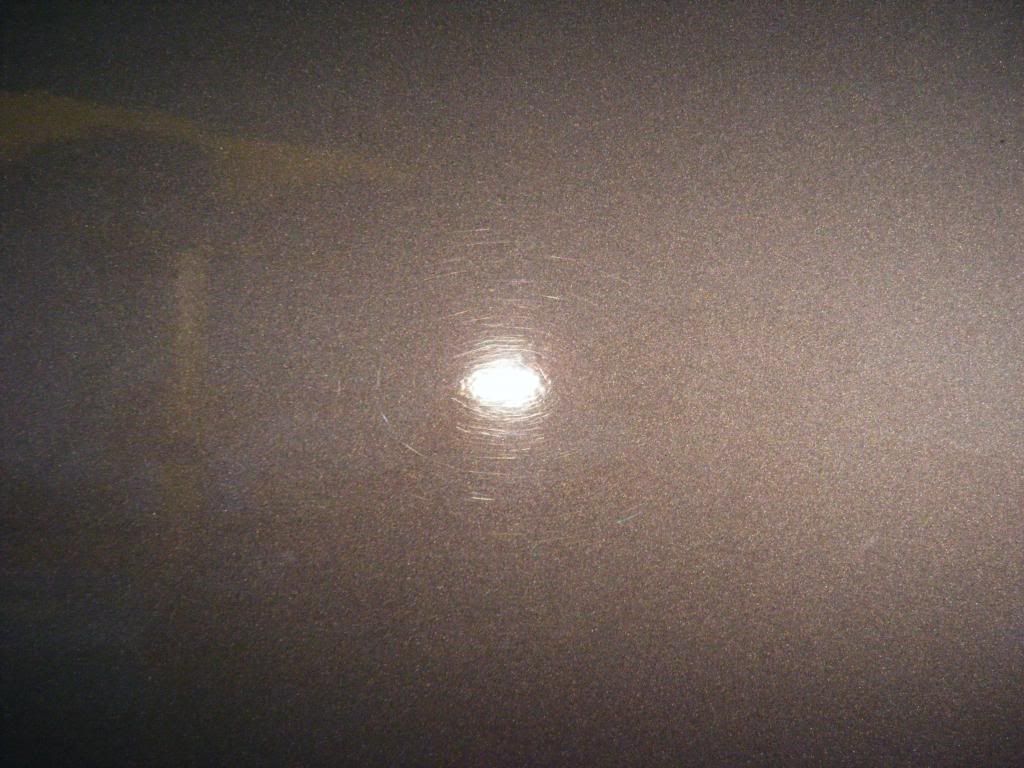

Another car showed the excellent preparation available from car dealerships - free hologramming!

Hows this for a 50/50?!!

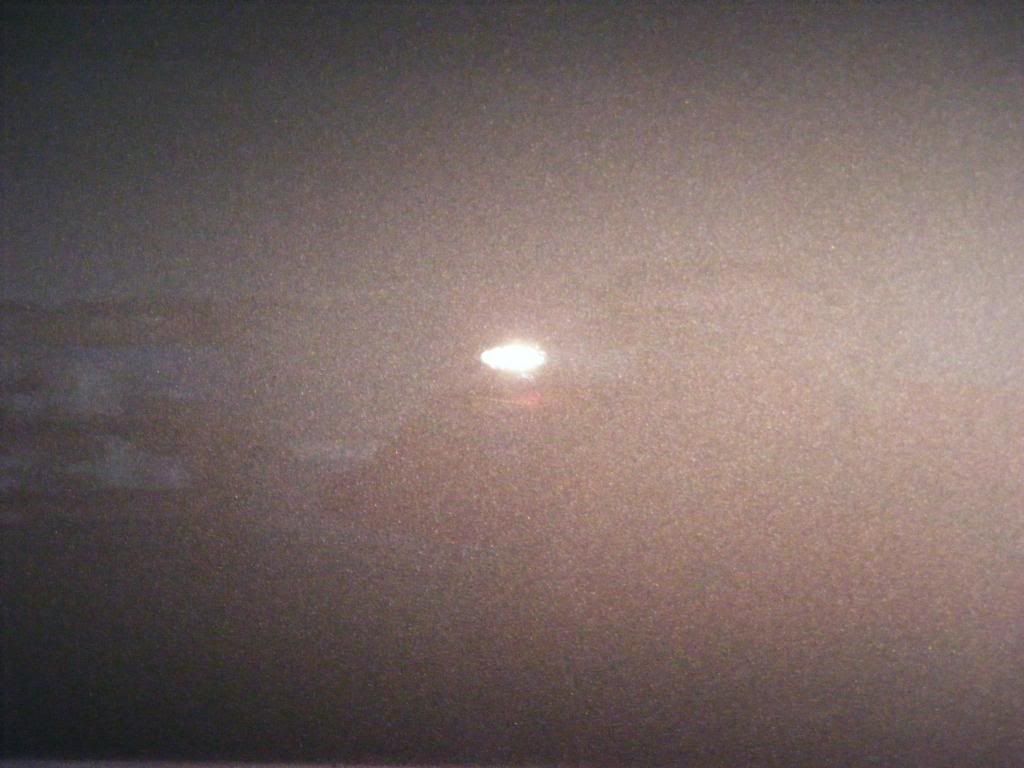

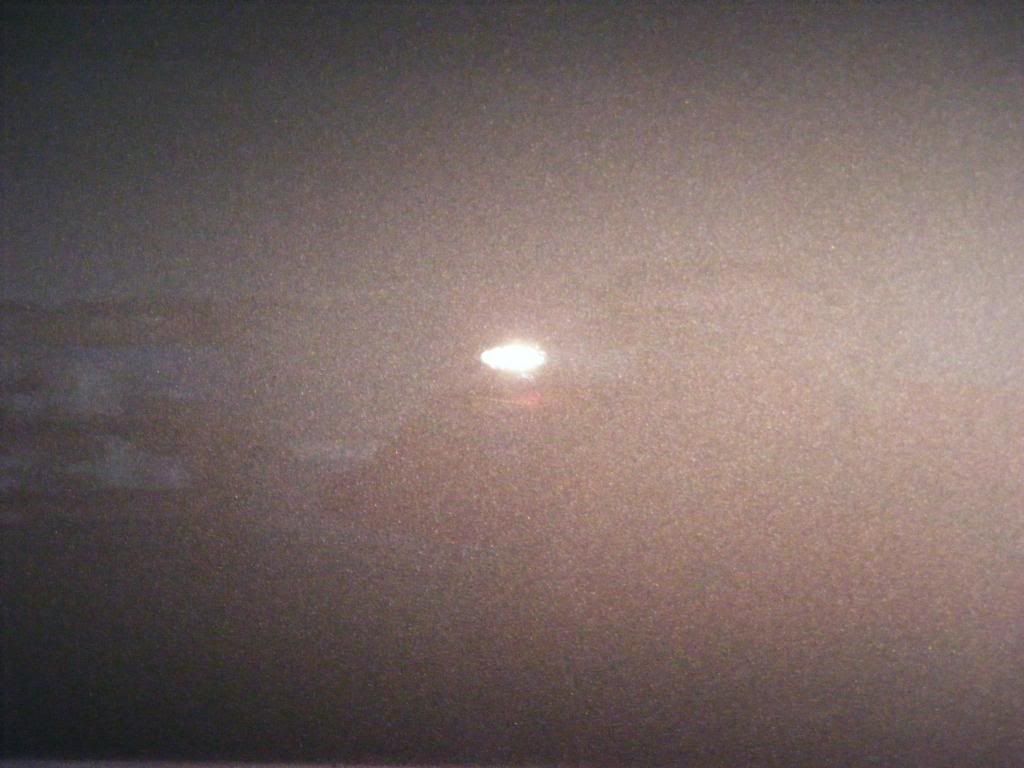

Deeper scratches were compounded with Fast Cut Plus, then 85RD to refine the finish, and a cracking piece of work achieved by the owner (FlyingfocRS) there!!

Best correct the rest now!

Gordon returned for more punishment! :lol: ...

Before:

During:

After:

A white Laguna was Eazy's challenge:

In action using Fast Cut then Ultrafine from 3M:

Excellent clarity and finish on the solid white in the afters...

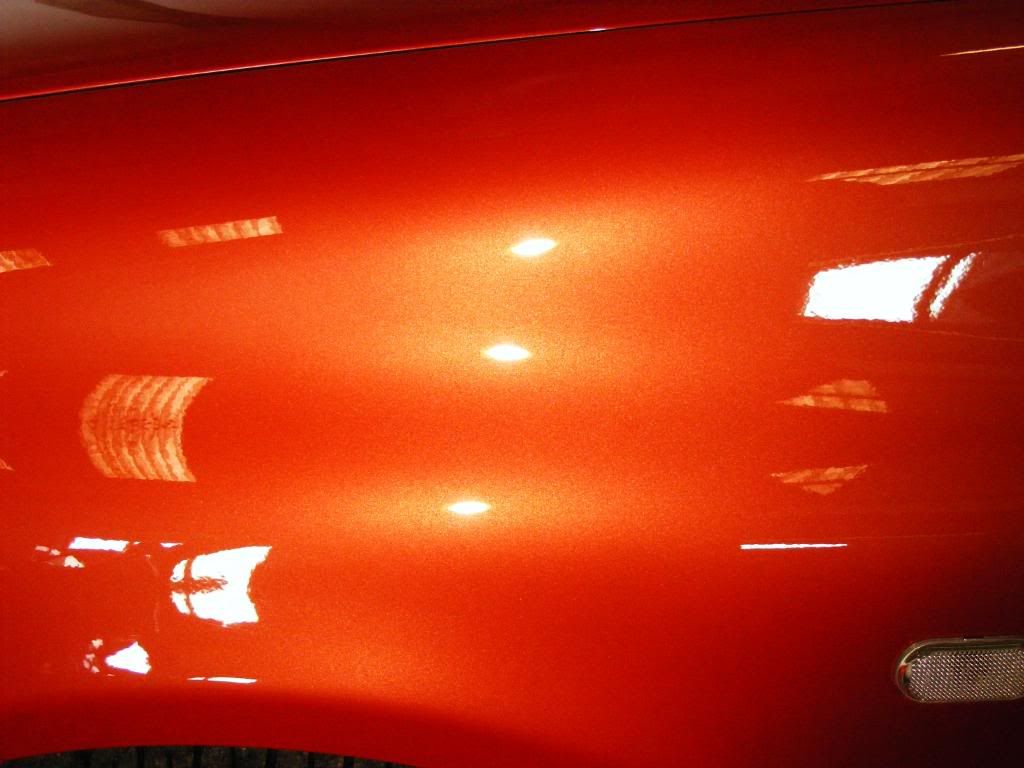

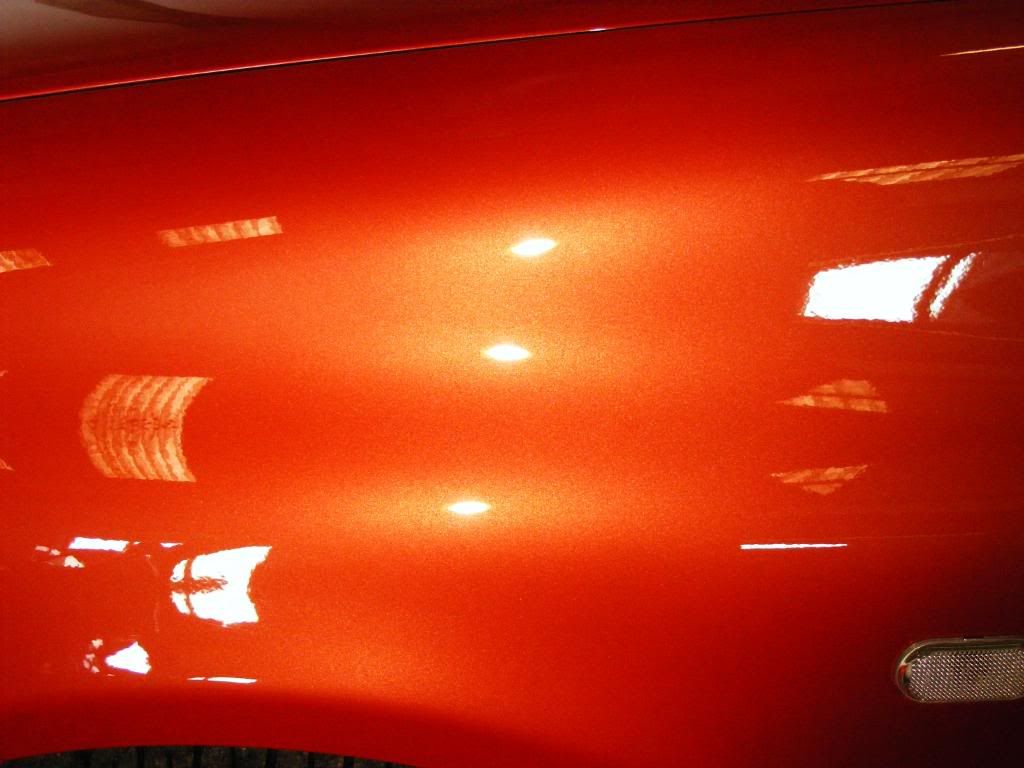

Sandro didn't have much in the way of marring or swirls on his cracking Clio 182, superb colour as well, but still got a nice burnish and refine with 106FF:

Cracking colour, and clarity...

Following the machine polishing workshop there was the opportunity to try out a few products - waxes and glazes and also the chance for folks to try out the Nanolex Glass Sealant that has impressed me of late, and also some of the new Meguiars #205 Ultra Finishing Polish.

All in all, another very enjoyable day and I look forward to meeting folks again either at the master class or at meets later in the year! :thumb:

First off, the "class photo"! :thumb:

The morning was, as always with these training days, spent on the test cars. First focussing on machine control on various panels to get a feeling for the best way to hold and guide the polisher - both on horizontal and vertical panels. The option to try two different "styles" of rotary offered folks the chance to see what suited them best and as expected, some liked the light weight Milwaukee while others preferred the old-school Makita.

Correction techniques were also examined, using a variety of polishes for the general correction, and also for more severe defect correction using compounds. It was the first outing for everyone for the new Menzerna 203S Power Finish which largely impressed those who used it (including me, and while it offers nothing "extra" in terms of cutting or finishing ability to the Menz range it offers an ideal polish for "enhancement" style single stage details where good correction and sharp finshing are required - you can now carry out with one polish what previously took two, but only on certain paints as I found good though 203S was, I could finish Intensive Polish down to match it to the naked eye on all but my softest paint panel).

We also looked at plastics and safe methods for polishing plastics panels by rotary, as well as a demonstration for what happens when plastic gets a bit too hot

After a break for lunch to consolidate what the morning session contained, and enjoy sandwiches and choc chip cookies made by Diane, we moved onto the afternoon session which is an open workshop for folks to try what they learned with any product they liked on their own cars

Kicking off with the Mini, and a couple of deeper scratches on the door...

Perfect for practising some localised compounding with a 4" pad,

All gone!

Whole door then polished with 203S, followed with 85RD,

Proud of his mum's work!

The day was too much for some :lol:

Another car showed the excellent preparation available from car dealerships - free hologramming!

Hows this for a 50/50?!!

Deeper scratches were compounded with Fast Cut Plus, then 85RD to refine the finish, and a cracking piece of work achieved by the owner (FlyingfocRS) there!!

Best correct the rest now!

Gordon returned for more punishment! :lol: ...

Before:

During:

After:

A white Laguna was Eazy's challenge:

In action using Fast Cut then Ultrafine from 3M:

Excellent clarity and finish on the solid white in the afters...

Sandro didn't have much in the way of marring or swirls on his cracking Clio 182, superb colour as well, but still got a nice burnish and refine with 106FF:

Cracking colour, and clarity...

Following the machine polishing workshop there was the opportunity to try out a few products - waxes and glazes and also the chance for folks to try out the Nanolex Glass Sealant that has impressed me of late, and also some of the new Meguiars #205 Ultra Finishing Polish.

All in all, another very enjoyable day and I look forward to meeting folks again either at the master class or at meets later in the year! :thumb: