imported_shine

New member

Here is one I did before the winter. A two-step correction was performed which removed a majority of the swirling but left some RIDS. Since this was a winter vehicle 476s was used for protection.

The truck was already washed so I started with removing wax residue around emblems and badges with a 50/50 mix of water and 91% Isopropyl Alcohol and a small brush, pointed q-tips, and microfiber towels while trying not to induce additional scratches.

After:

The truck was clayed using ONR at QD ratio and DP gray. Since this vehicle gets to venture into salty winter roads every year and has never been clayed these results weren't all that surprising:

After claying the car was wiped down with 50/50 mix of water and 91% Isopropyl Alcohol. The next step was to reduce or remove this scuff/scratches on one of the rear panels above the wheel well.

Before doing that I got thickness readings on all body panels, especially around where the scuff was. Overall everything was plently thick, with readings above 7 mils many places and sometimes exceeding 8. A few quick applications of M105 and a CCS 4" green pad was all that was needed to remove most of most of the scuff. The time I allowed M105 to work was very short and I did not apply much pressure. In other words, the more traditional method was used, not like the new KB method. RPMs were kept below 1000.

RPMs were kept below 1000.

After:

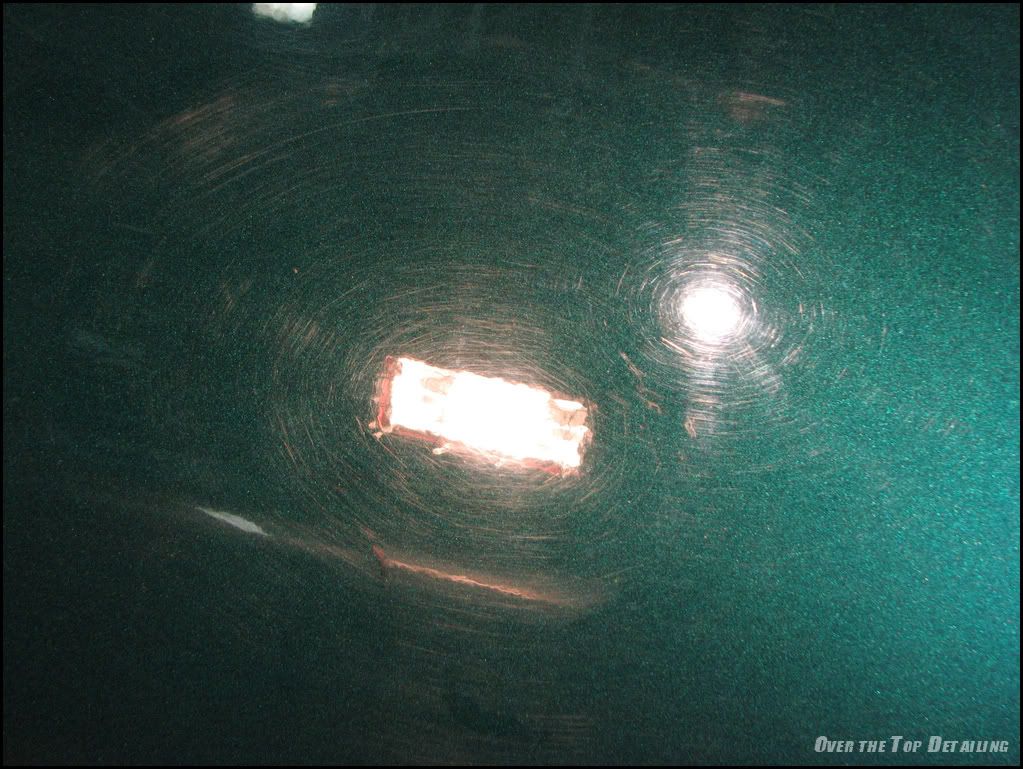

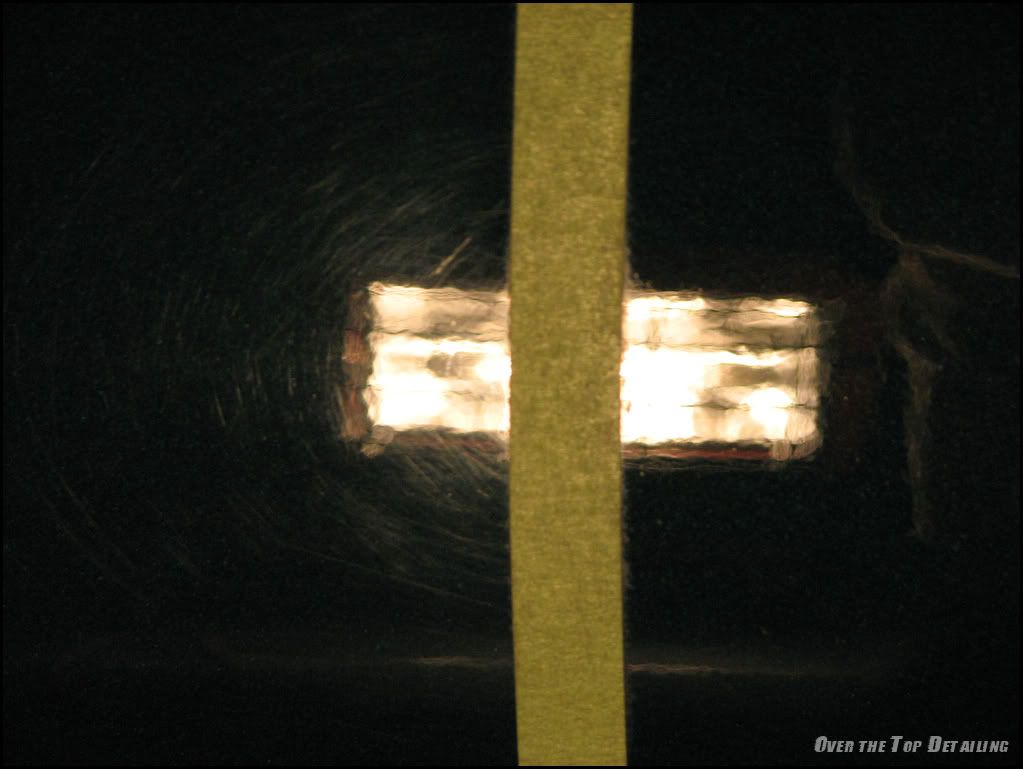

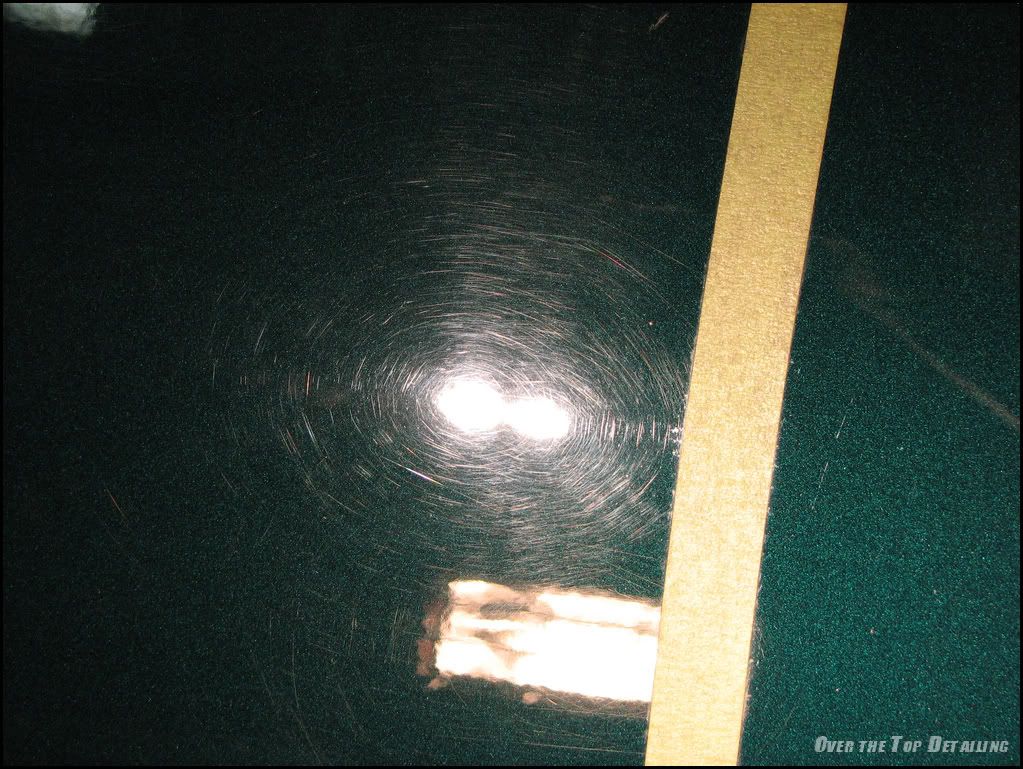

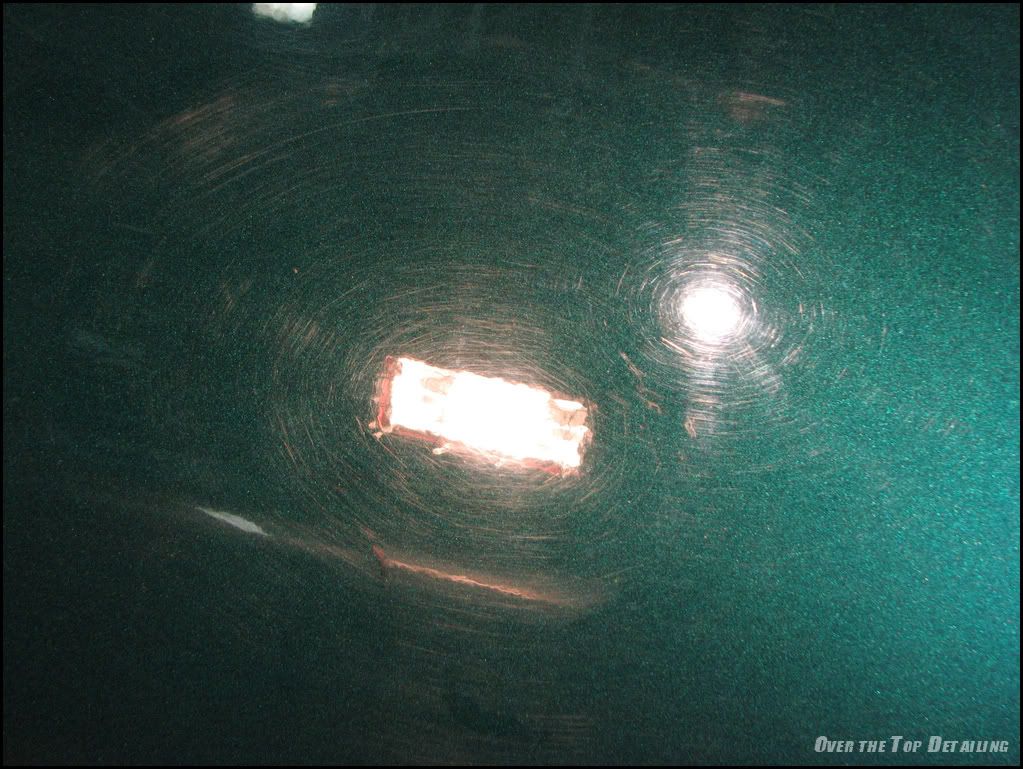

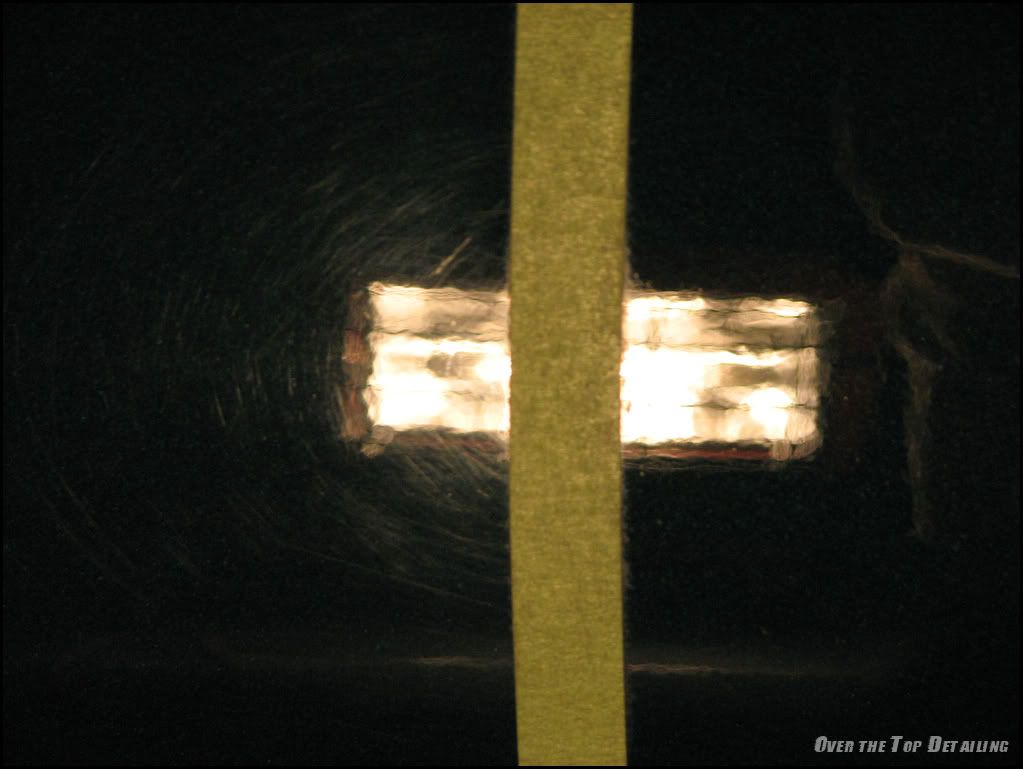

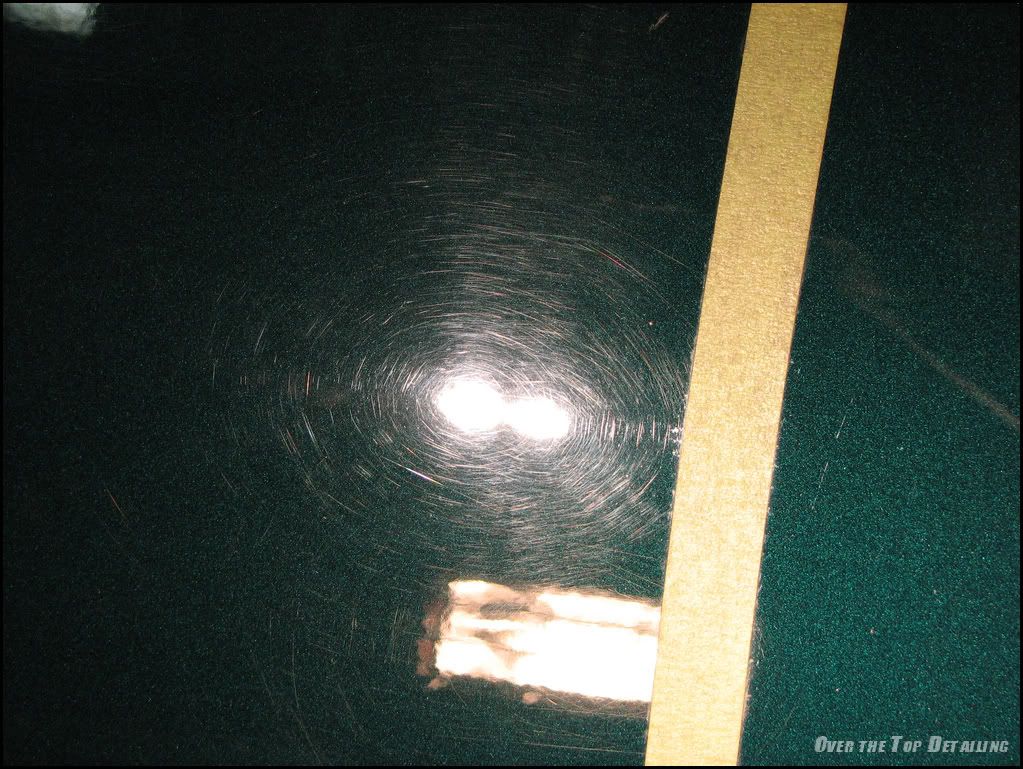

Next was to tape up all emblems and trim, closely inspect the paint, and test a few polishes. Here is what I saw with the Brinkmann Xenon and halogen lighting:

I decided to complete my 2-step with SIP on a 6.5" German green foam CCS pad followed by 3M UF on a 6.5" black CCS pad with the rotary. That day SIP decided to be a total pain by gumming up and spitting clumps of polish...but I fought it to the end. It also felt the need to cement itself to the paint at times. UF was worked at 1500 RPM at most and then slowed down to around 900 before finally removing. UF was so nice to work with after fighting SIP, but it did sling some.

UF was worked at 1500 RPM at most and then slowed down to around 900 before finally removing. UF was so nice to work with after fighting SIP, but it did sling some.

50/50 shot:

Before:

After: As you can see, there was some deeper RIDS or swirls left over but perfection wasn't the goal.

Camera flash and Brinkmann revealing defects:

After: (with some smearing below the light)

Before and after with the halogens:

More:

After isopropyl alcohol wipedown but prior to LSP:

And finally after Collinite 476S application:

Out in the sun:

Thanks for viewing!

The truck was already washed so I started with removing wax residue around emblems and badges with a 50/50 mix of water and 91% Isopropyl Alcohol and a small brush, pointed q-tips, and microfiber towels while trying not to induce additional scratches.

After:

The truck was clayed using ONR at QD ratio and DP gray. Since this vehicle gets to venture into salty winter roads every year and has never been clayed these results weren't all that surprising:

After claying the car was wiped down with 50/50 mix of water and 91% Isopropyl Alcohol. The next step was to reduce or remove this scuff/scratches on one of the rear panels above the wheel well.

Before doing that I got thickness readings on all body panels, especially around where the scuff was. Overall everything was plently thick, with readings above 7 mils many places and sometimes exceeding 8. A few quick applications of M105 and a CCS 4" green pad was all that was needed to remove most of most of the scuff. The time I allowed M105 to work was very short and I did not apply much pressure. In other words, the more traditional method was used, not like the new KB method.

After:

Next was to tape up all emblems and trim, closely inspect the paint, and test a few polishes. Here is what I saw with the Brinkmann Xenon and halogen lighting:

I decided to complete my 2-step with SIP on a 6.5" German green foam CCS pad followed by 3M UF on a 6.5" black CCS pad with the rotary. That day SIP decided to be a total pain by gumming up and spitting clumps of polish...but I fought it to the end. It also felt the need to cement itself to the paint at times.

50/50 shot:

Before:

After: As you can see, there was some deeper RIDS or swirls left over but perfection wasn't the goal.

Camera flash and Brinkmann revealing defects:

After: (with some smearing below the light)

Before and after with the halogens:

More:

After isopropyl alcohol wipedown but prior to LSP:

And finally after Collinite 476S application:

Out in the sun:

Thanks for viewing!