imported_ChrisNJ

New member

First. I suck at taking pictures. I mean, really. I only did the hood and 2 front quarter panels yet managed a couple of good pics. Somehow managed to make my white truck look yellow in most of the pics too.

Next thing I learned,... I love using a rotary. I'm no pro at it yet obviously, but damn, what a nice difference. Its not as scary as I thought either really. Its quiet, smooth, effective... I'm in love :heelclick lol

Now, this was on a white truck, which I think makes things a little easier, but I cant find any holograms or buffer trails. I did follow up w/ the udm to finish it off which is probably why though.

First let me note what I used.

Makita 9227

Purple Foamed Wool 6.5" pad w/ OP (2 passes)

(finished w/ udm and OP on wht pad)

Heres some things I noted and my technique, so hopefully people can comment on them. I read a lot about guys laying down a line of product on the panel itself. I chose to apply it to the pad and start how I would w/ the udm. place it on the panel and start at probably 600 just to spread it real quick, over the section, then bump it up to ~1400rpm. I did mostly east/west passes w/ just one or two north/south passes thrown in. Towards the end, I did notice the pad/machine want to jump every once in a while. Too much product building up? The other things I noticed is that it does want to "grab" and do its own thing here and there. Otherwise, it seemed pretty straight forward.

Heres a few pics of the job. Again, sorry about the quality. My main light source was the halogens w/ some poor overhead lights for general lighting. Tell me how I did for my first time. I was certainly a little reluctant to go too aggressive. I'm sure I could've removed a little more of the remaining heavy scratches, but was nervous on how much to go.

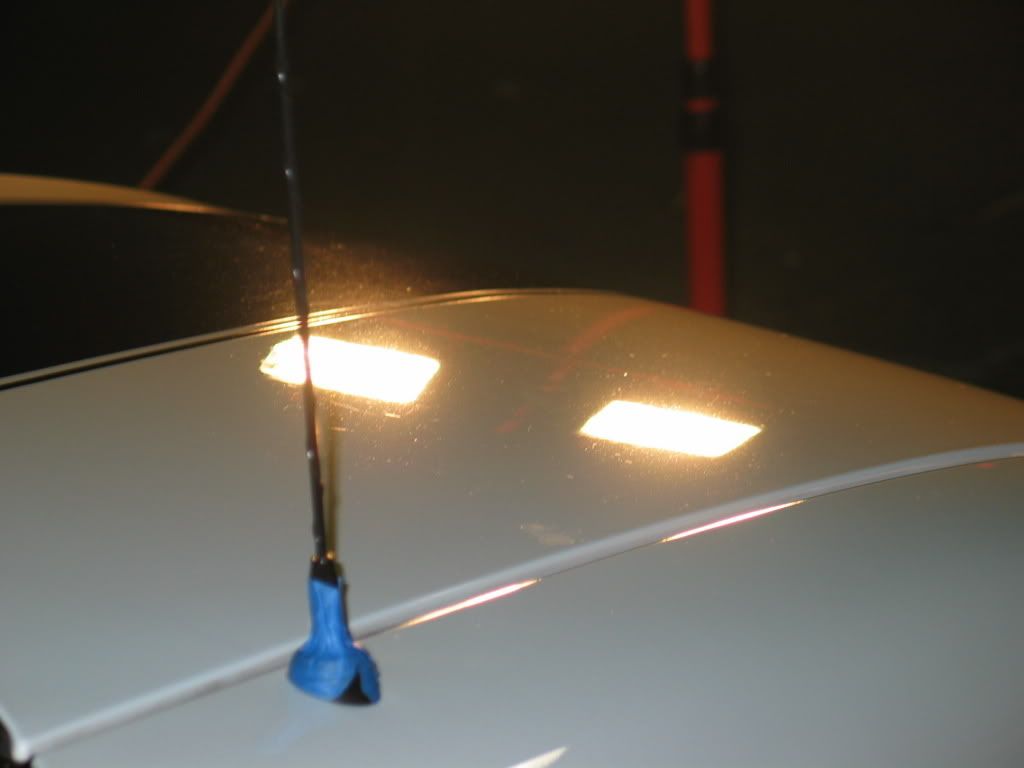

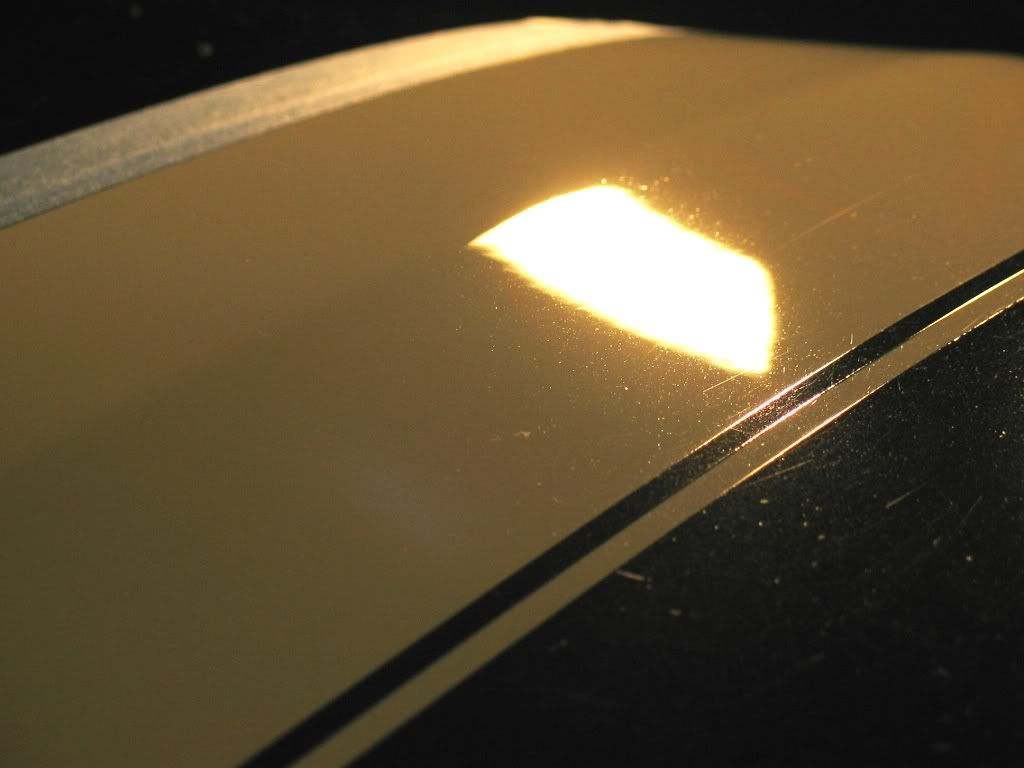

Before: Whole hood looked like this. Actually, who am I kidding, the whole truck looks like this, lol.

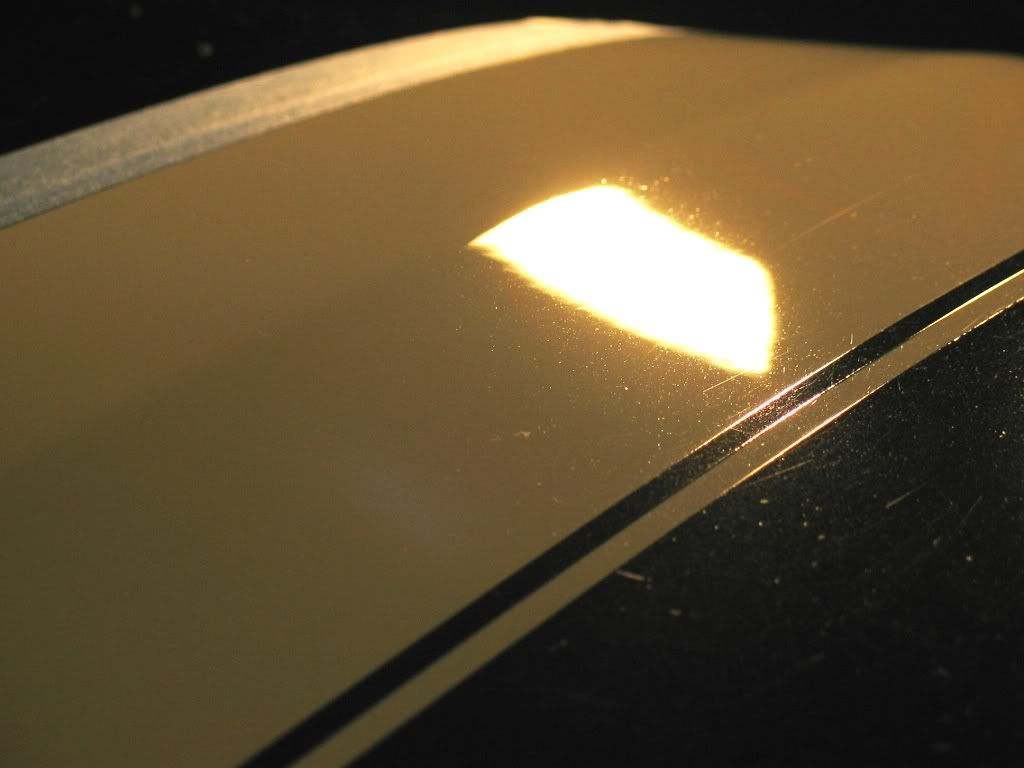

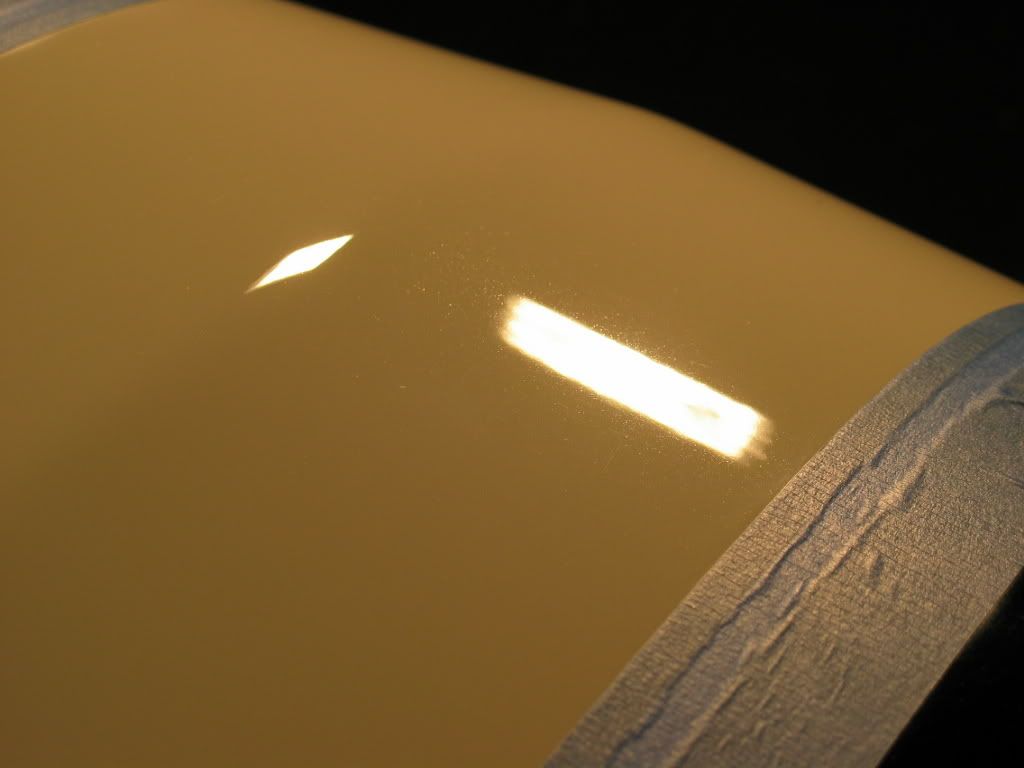

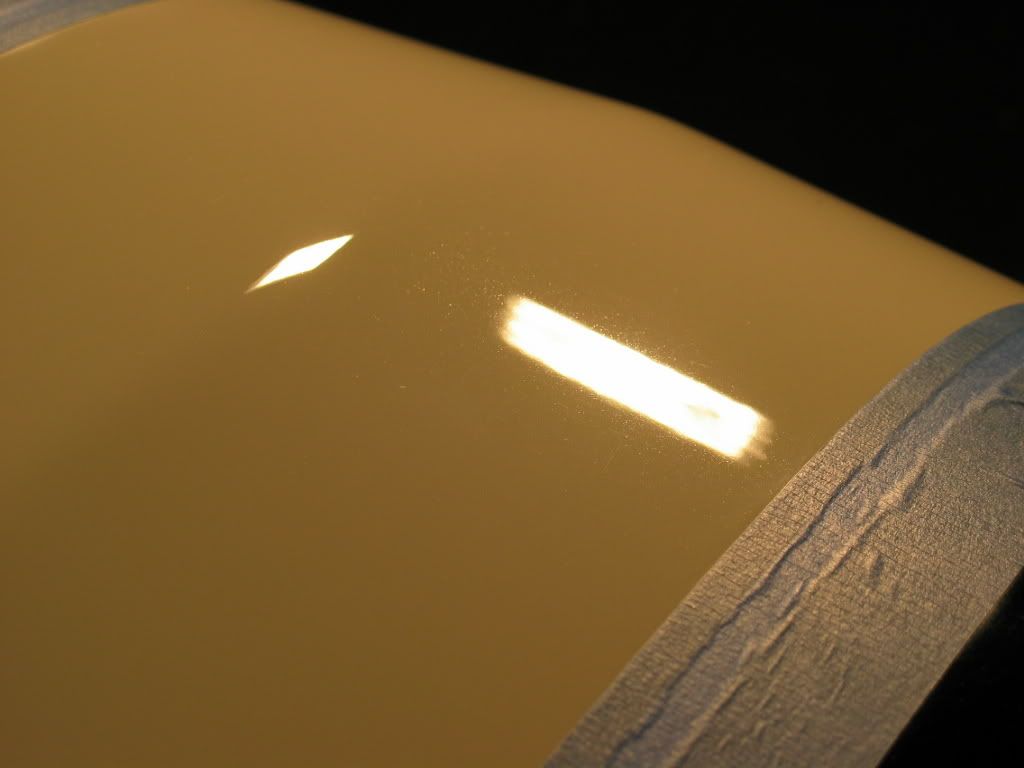

Some afters. Again, OP on purple foamed wool, starting at ~600ish, bump it up to 1400, then backed it down for one or two final passes.

Next thing I learned,... I love using a rotary. I'm no pro at it yet obviously, but damn, what a nice difference. Its not as scary as I thought either really. Its quiet, smooth, effective... I'm in love :heelclick lol

Now, this was on a white truck, which I think makes things a little easier, but I cant find any holograms or buffer trails. I did follow up w/ the udm to finish it off which is probably why though.

First let me note what I used.

Makita 9227

Purple Foamed Wool 6.5" pad w/ OP (2 passes)

(finished w/ udm and OP on wht pad)

Heres some things I noted and my technique, so hopefully people can comment on them. I read a lot about guys laying down a line of product on the panel itself. I chose to apply it to the pad and start how I would w/ the udm. place it on the panel and start at probably 600 just to spread it real quick, over the section, then bump it up to ~1400rpm. I did mostly east/west passes w/ just one or two north/south passes thrown in. Towards the end, I did notice the pad/machine want to jump every once in a while. Too much product building up? The other things I noticed is that it does want to "grab" and do its own thing here and there. Otherwise, it seemed pretty straight forward.

Heres a few pics of the job. Again, sorry about the quality. My main light source was the halogens w/ some poor overhead lights for general lighting. Tell me how I did for my first time. I was certainly a little reluctant to go too aggressive. I'm sure I could've removed a little more of the remaining heavy scratches, but was nervous on how much to go.

Before: Whole hood looked like this. Actually, who am I kidding, the whole truck looks like this, lol.

Some afters. Again, OP on purple foamed wool, starting at ~600ish, bump it up to 1400, then backed it down for one or two final passes.