imported_rydawg1

New member

Hi guys

This is a 2006 Ford GT supercar that was in need of some serious attention. The owner had previously waxed it a bunch of times trying to hide the defects, but it just wasn't working. I recently did another blue GT (30 hour correction job) like this one and the owner of that one had seen this one at a car show and told him about my work and said I was the one to contact to perfect it like his. He also had other people at the car show tell him about my work and they all gave him my number, so he decided to contact me immediately and bring me the car to see what I could do with it. He also said he owned a meat market in Boston and said he would bring me some steak on his way over. That got my attention!

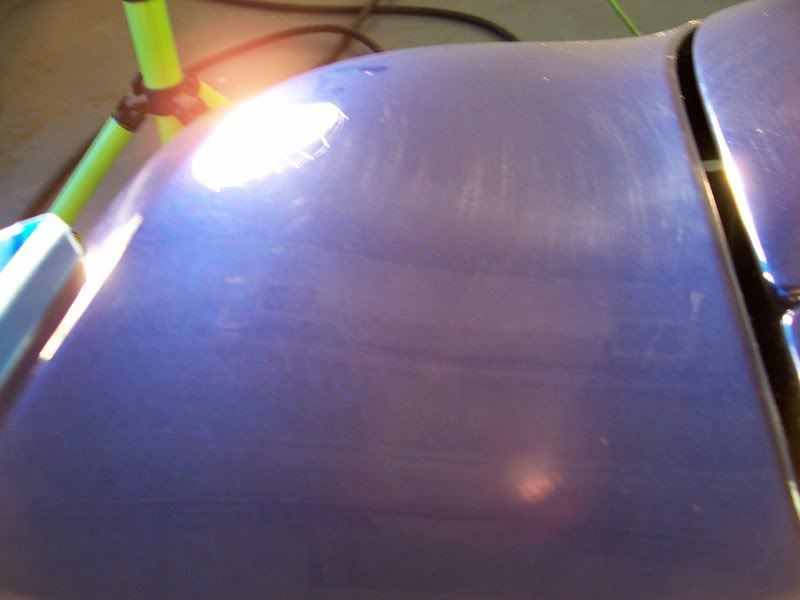

Upon inspection, it had the normal marring, scuffs, severe dullness, wet sand marks and pigtail sanding marks still from the Saleen factory, swirls, wax in crevices, buffing trails, acid rain spots, and tons of dirt contaminated on the body. I explained the whole process from start to finish and what was involved and told him it would take average 40-50 hours to make it 100%. He told me to do what ever it takes to make the paint flawless.

I knew I had my work cut out for me, especially having experience with other Ford GT's that I have corrected. The paint that they use on these are not the greatest and there is a ton of divets, channels, contours, tons of taping, un taping, re taping, etc..... The bodies on these are not small neither and there is a LOT of paintwork to polish on these. If any of you guys have ever polished one of these, you know exactly what I mean. You have to tape off the rear vents just to wash it. I used 2 rolls of tape on this beauty for the correction process.

I started by washing it and removing all the wax so I can get a 100% clean slate to polish. I spent 6 hours removing the old wax/silicones from the paint and crevices, so polishing would go perfect with no issues at all. I then removed some of the clear film on the car so I could polish under them and then have new clear film installed after.

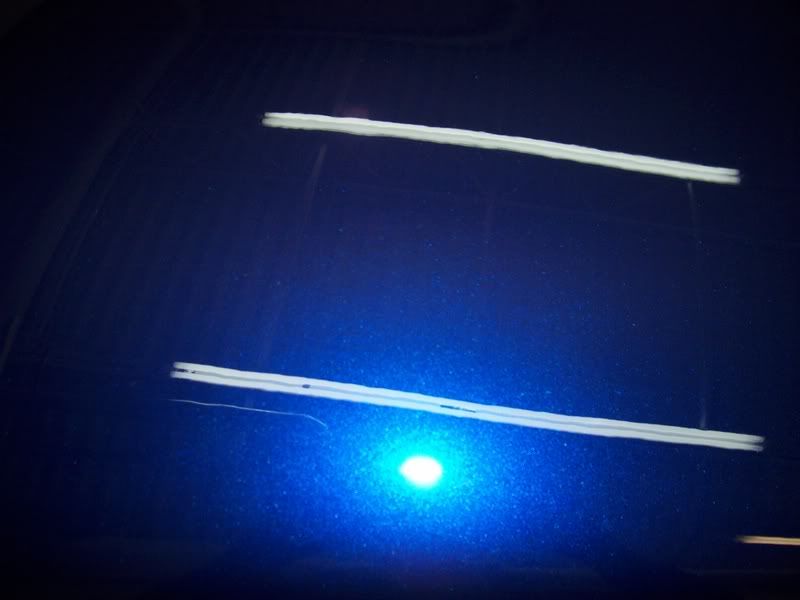

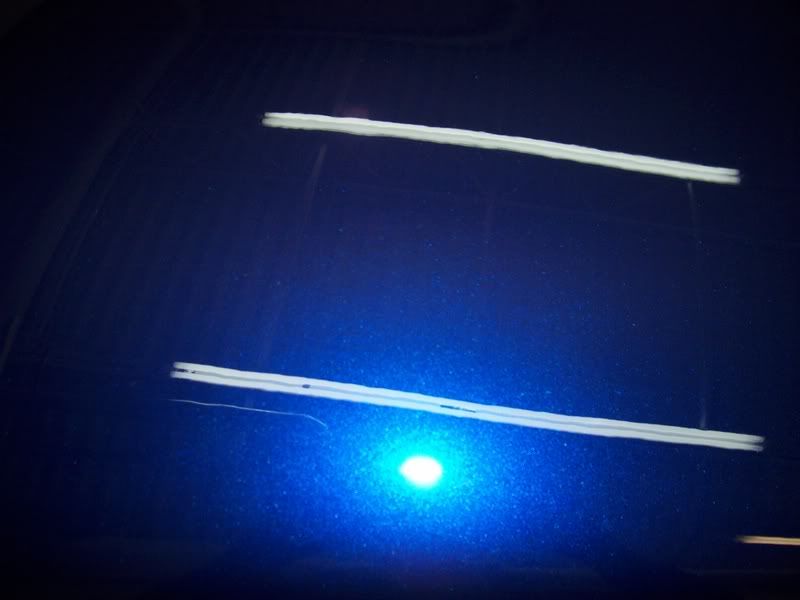

I then spent a few hours inspecting all the paint and trying to examine everything so I know exactly what had to be done. I mapped out the car on paper and every section needed some serious attention and then went into the office and put together a perfect game plan. I had to do some wetsanding to remove some of the minor pigtail marks on the channels of the doors. I spot sanded with 4000, 7000, and 12,000 refining the surface to a perfect flat defect free surface.

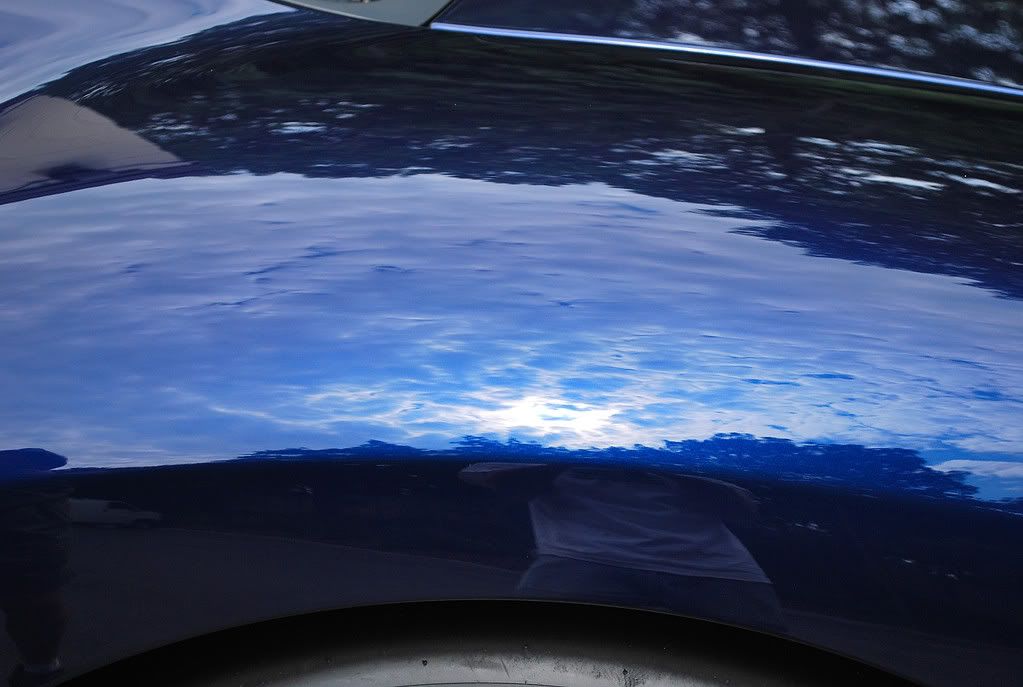

I then proceeded onto the polishing with numerous 3M and Menzerna compounds and polishes to get it 100%. I spent 20 hours alone just burnishing the paint on this car to an ultimate high gloss. Washed the whole car (extremely gentle) getting all the dust off in the cracks, jambs, and crevices, etc. Then dried the whole car off and used 91% IPA on the whole car and inspected every inch to make sure it was perfect. The owner came by and inspected it with me to make sure it was perfect before I sealed it. He was completely amazed at how amazing it looked and could not believe there was no wax on it. I soaked the whole car in alcohol in front of him showing the trueness and the clarity of the paint.

I chose to seal it with Zaino for numerous reasons. Washing this car is a long job on it's own, so I wanted something that was non oily and very slick, repels dust and easy to maintain with long protection. I applied 2 coats of Z5pro to make sure it was sealed perfect and then topped it with Z8. I couldn't take pics that day when it was done cause I did not have my camera, but I got him to come by a few weeks after so I could get some after pics.

The owner was so extremely happy with this car that he had me do his Porsche too. He also gave me 5 pounds of Kobe beef as a tip for both cars. I had no idea what it was at first, but I asked a few people and they said it was $100 a pound. It was the best meat I have ever had. YUM!!!!! The owner was the coolest guy and we are now good friends.

Products used

Micro surface 4000-12,000 grit sanding sheets

Micro surface black wool pad

3M compounds (2 steps)

Menzerna polishes 6 steps (double staged different polishes to get the ultimate gloss and absolute perfection)

LC foam pads

Zaino products

Installed new clear film on roof and sides

Total time was roughly 50 hours to make the paint 100%. When it comes to a car like this and a job like this there are no corners to cut. He was paying for perfection and was an investment for the car. I just stay focused and try not to think about how much work is involved and try not to get overwhelmed. On the finishing polish stage day, I worked 20 hours that day so I would keep the same momentum so the finish would be perfectly balanced and precise.

The after pics were taken a few weeks after the job so I could get some sun pics. He came by for a wash, but it was not dirty at all, so we did a z6 and z8 wipedown. I also taught him the first day how to do z6/z8 wipedowns without marring the paint and I must have to say I am very impressed with the amazing job that he is doing. The paint is still 100% defect free.

Thanks for looking at my work! I will try to post up some other jobs too.

Some during process pics

AFTER PICS DOWN BELOW IN POST #3

This is a 2006 Ford GT supercar that was in need of some serious attention. The owner had previously waxed it a bunch of times trying to hide the defects, but it just wasn't working. I recently did another blue GT (30 hour correction job) like this one and the owner of that one had seen this one at a car show and told him about my work and said I was the one to contact to perfect it like his. He also had other people at the car show tell him about my work and they all gave him my number, so he decided to contact me immediately and bring me the car to see what I could do with it. He also said he owned a meat market in Boston and said he would bring me some steak on his way over. That got my attention!

Upon inspection, it had the normal marring, scuffs, severe dullness, wet sand marks and pigtail sanding marks still from the Saleen factory, swirls, wax in crevices, buffing trails, acid rain spots, and tons of dirt contaminated on the body. I explained the whole process from start to finish and what was involved and told him it would take average 40-50 hours to make it 100%. He told me to do what ever it takes to make the paint flawless.

I knew I had my work cut out for me, especially having experience with other Ford GT's that I have corrected. The paint that they use on these are not the greatest and there is a ton of divets, channels, contours, tons of taping, un taping, re taping, etc..... The bodies on these are not small neither and there is a LOT of paintwork to polish on these. If any of you guys have ever polished one of these, you know exactly what I mean. You have to tape off the rear vents just to wash it. I used 2 rolls of tape on this beauty for the correction process.

I started by washing it and removing all the wax so I can get a 100% clean slate to polish. I spent 6 hours removing the old wax/silicones from the paint and crevices, so polishing would go perfect with no issues at all. I then removed some of the clear film on the car so I could polish under them and then have new clear film installed after.

I then spent a few hours inspecting all the paint and trying to examine everything so I know exactly what had to be done. I mapped out the car on paper and every section needed some serious attention and then went into the office and put together a perfect game plan. I had to do some wetsanding to remove some of the minor pigtail marks on the channels of the doors. I spot sanded with 4000, 7000, and 12,000 refining the surface to a perfect flat defect free surface.

I then proceeded onto the polishing with numerous 3M and Menzerna compounds and polishes to get it 100%. I spent 20 hours alone just burnishing the paint on this car to an ultimate high gloss. Washed the whole car (extremely gentle) getting all the dust off in the cracks, jambs, and crevices, etc. Then dried the whole car off and used 91% IPA on the whole car and inspected every inch to make sure it was perfect. The owner came by and inspected it with me to make sure it was perfect before I sealed it. He was completely amazed at how amazing it looked and could not believe there was no wax on it. I soaked the whole car in alcohol in front of him showing the trueness and the clarity of the paint.

I chose to seal it with Zaino for numerous reasons. Washing this car is a long job on it's own, so I wanted something that was non oily and very slick, repels dust and easy to maintain with long protection. I applied 2 coats of Z5pro to make sure it was sealed perfect and then topped it with Z8. I couldn't take pics that day when it was done cause I did not have my camera, but I got him to come by a few weeks after so I could get some after pics.

The owner was so extremely happy with this car that he had me do his Porsche too. He also gave me 5 pounds of Kobe beef as a tip for both cars. I had no idea what it was at first, but I asked a few people and they said it was $100 a pound. It was the best meat I have ever had. YUM!!!!! The owner was the coolest guy and we are now good friends.

Products used

Micro surface 4000-12,000 grit sanding sheets

Micro surface black wool pad

3M compounds (2 steps)

Menzerna polishes 6 steps (double staged different polishes to get the ultimate gloss and absolute perfection)

LC foam pads

Zaino products

Installed new clear film on roof and sides

Total time was roughly 50 hours to make the paint 100%. When it comes to a car like this and a job like this there are no corners to cut. He was paying for perfection and was an investment for the car. I just stay focused and try not to think about how much work is involved and try not to get overwhelmed. On the finishing polish stage day, I worked 20 hours that day so I would keep the same momentum so the finish would be perfectly balanced and precise.

The after pics were taken a few weeks after the job so I could get some sun pics. He came by for a wash, but it was not dirty at all, so we did a z6 and z8 wipedown. I also taught him the first day how to do z6/z8 wipedowns without marring the paint and I must have to say I am very impressed with the amazing job that he is doing. The paint is still 100% defect free.

Thanks for looking at my work! I will try to post up some other jobs too.

Some during process pics

AFTER PICS DOWN BELOW IN POST #3