imported_Dave KG

New member

Sunday was another detailing treat for me... a chance to work on one of my favourite Ferraris, the 355, with a simply beautiful shape and in the gorgeous rosso corsa deep red

Charlie, the owner, was keen to learn machine polishing and so opted for an Assisted Tuition Detail. That is, rather than me simply turning up and detailing the car (as normal for details ), Charlie was to play an active part in the detail learning the ropes and the techniques as we went under watchful eye... Think of it as a hands-on detail, where you get a chance to have your car professionally detailed but also are able to take part and get the satisfaction of achieving the results yourself and learning the techniques all in one.

), Charlie was to play an active part in the detail learning the ropes and the techniques as we went under watchful eye... Think of it as a hands-on detail, where you get a chance to have your car professionally detailed but also are able to take part and get the satisfaction of achieving the results yourself and learning the techniques all in one.

The car had been washed and clayed before I arrived, so it was a case of being able to go straight into the machine polishing... both DA and rotary polishers were used on the day, using Menzerna PO85RD3.02 Intensive Polish on polishing pads to correct the swirls and 95% of the RDS as well, followed by Menzerna PO85RD Final Finish to burnish the finish to a deep gloss ready for protection.

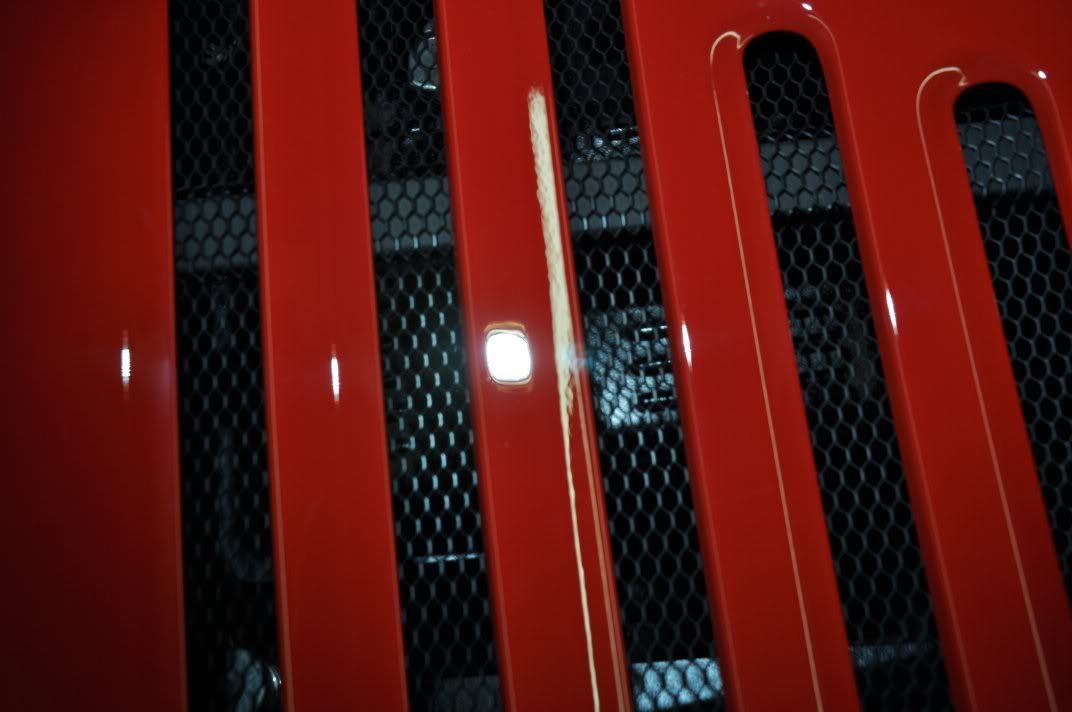

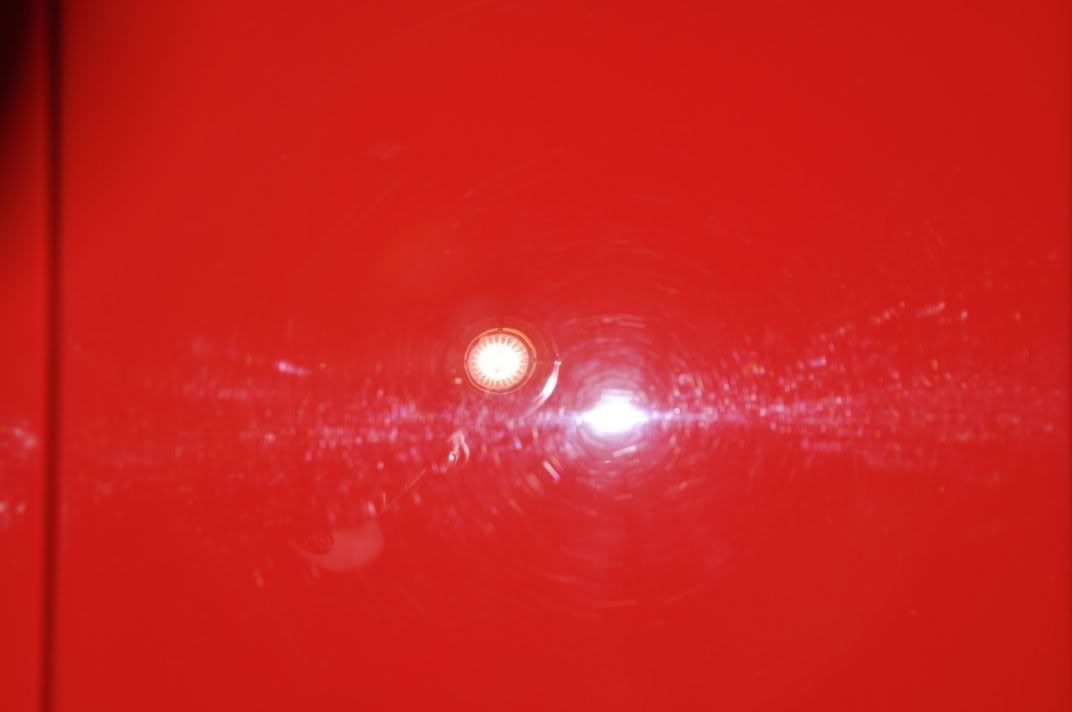

The paintwork beforehand:

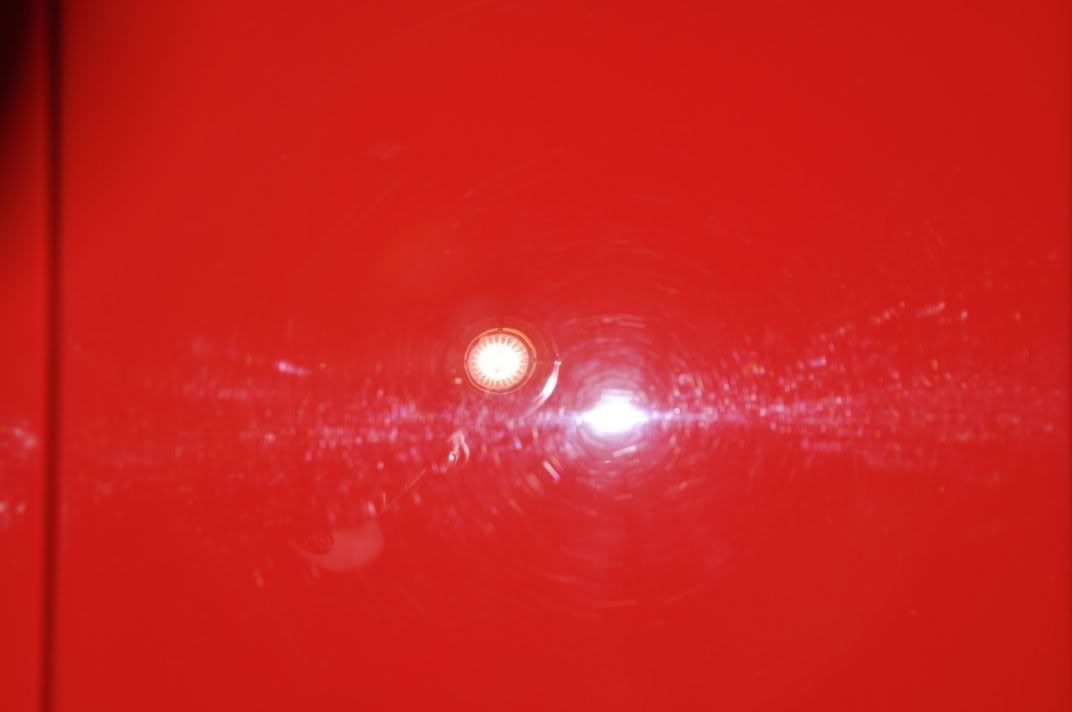

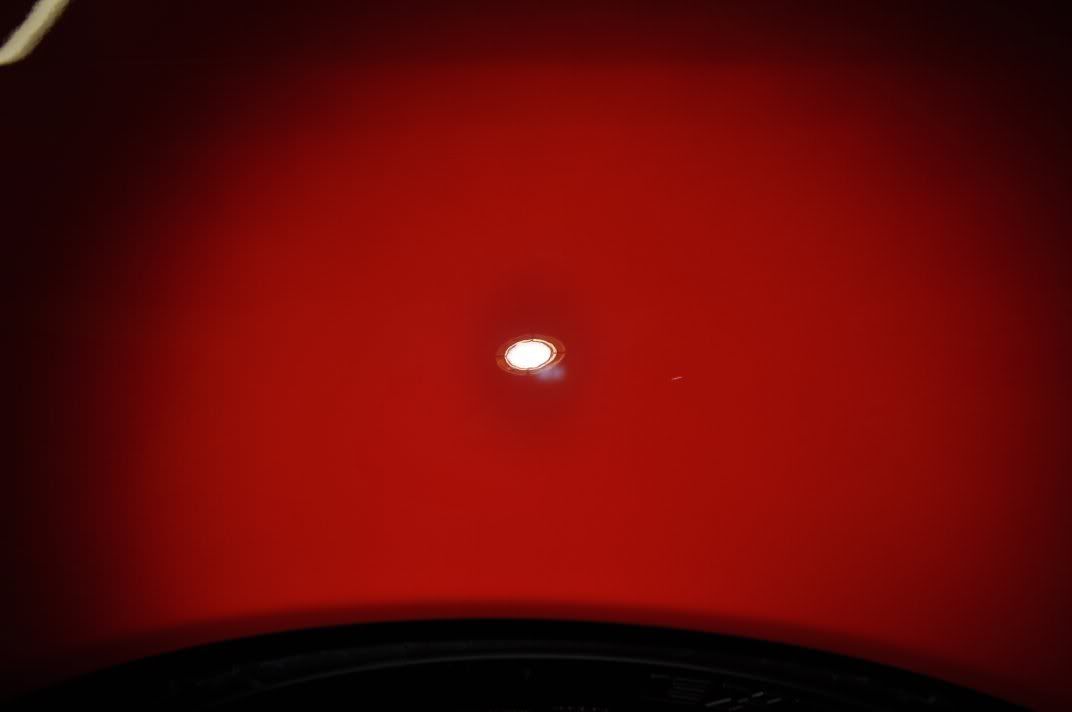

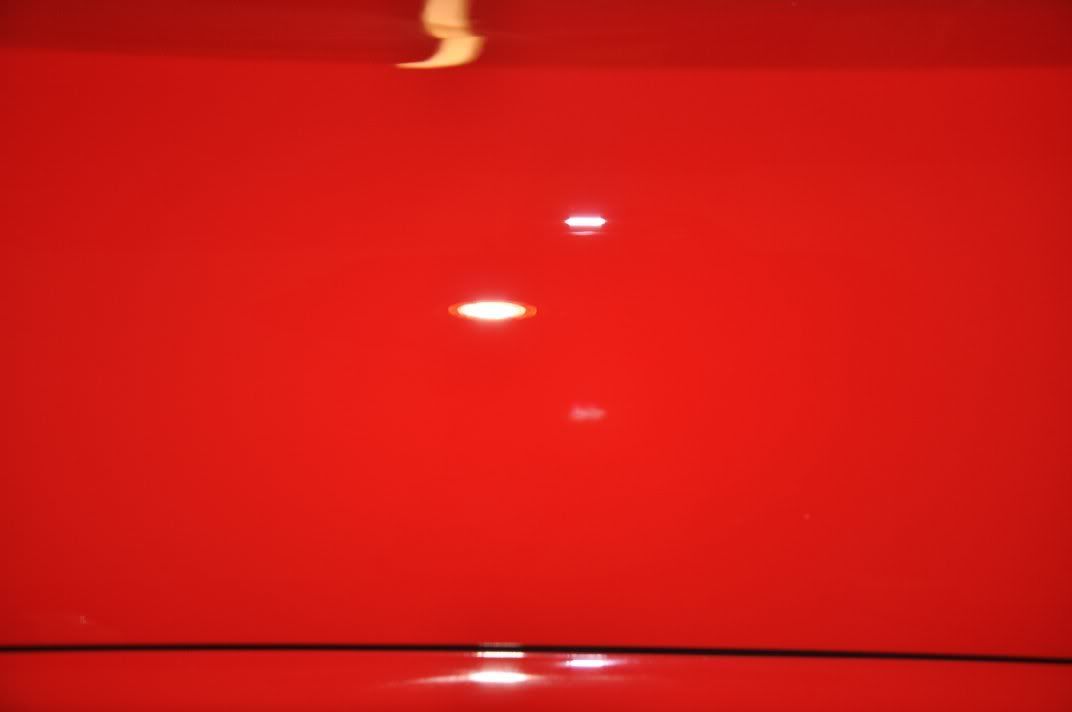

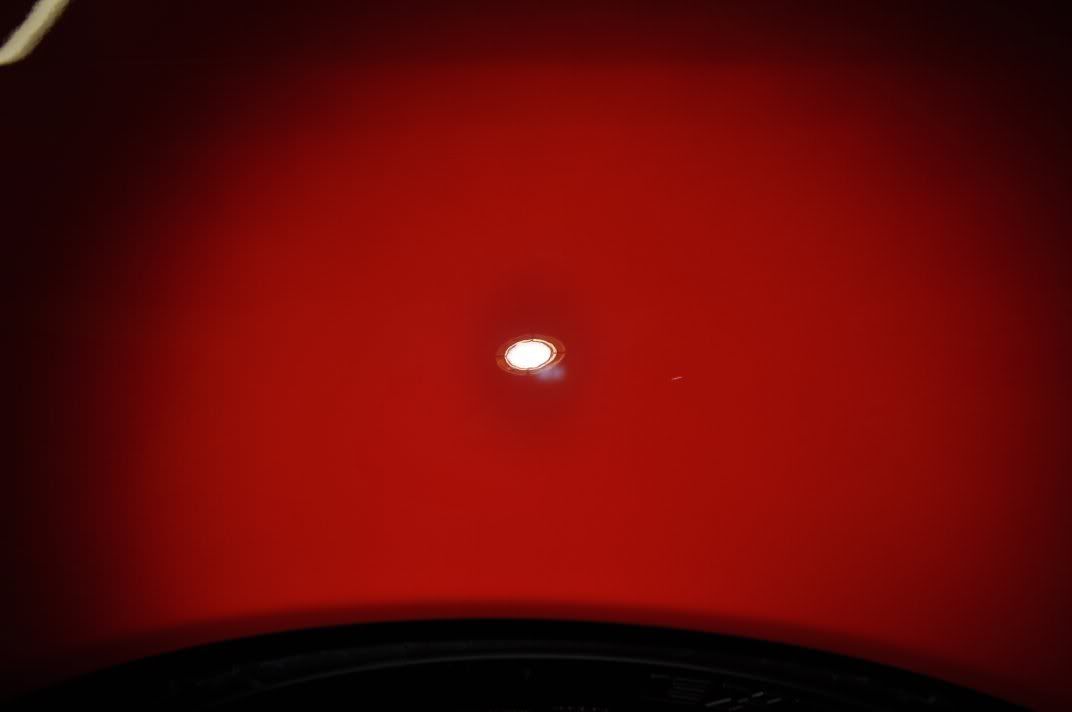

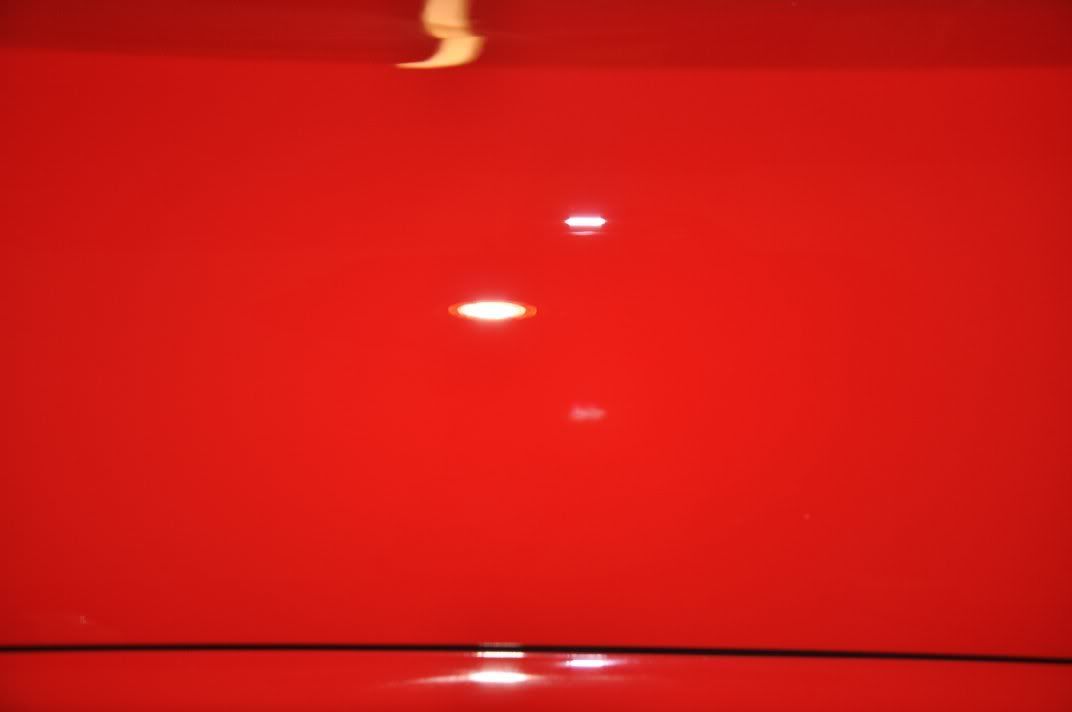

And some afters (note that these were taken during the detail, so some regions still not machined in these photographs - makes for some good quasi-50/50s ):

):

Charlie in action with the PC:

Despite this though, Charlie took best to the rotary polisher - taking to it like a duck to water in fact, and seemed to be a lot more at home with the "harder to use" machine... the benefit of this session was Charlie had originally intended to buy a G220, but after finding machine control and results were better with the rotary, he is now opting for the machine he prefers in use

Charlie, the owner, was keen to learn machine polishing and so opted for an Assisted Tuition Detail. That is, rather than me simply turning up and detailing the car (as normal for details

The car had been washed and clayed before I arrived, so it was a case of being able to go straight into the machine polishing... both DA and rotary polishers were used on the day, using Menzerna PO85RD3.02 Intensive Polish on polishing pads to correct the swirls and 95% of the RDS as well, followed by Menzerna PO85RD Final Finish to burnish the finish to a deep gloss ready for protection.

The paintwork beforehand:

And some afters (note that these were taken during the detail, so some regions still not machined in these photographs - makes for some good quasi-50/50s

Charlie in action with the PC:

Despite this though, Charlie took best to the rotary polisher - taking to it like a duck to water in fact, and seemed to be a lot more at home with the "harder to use" machine... the benefit of this session was Charlie had originally intended to buy a G220, but after finding machine control and results were better with the rotary, he is now opting for the machine he prefers in use