ktorres1120

New member

So after reading a bunch of threads on here I got a good amount of people saying that burning the paint with a rotary is harder than everyone thinks and to not be afraid of it. Well, my lack of experience and itchy rotary trigger finger looks like got me in to some trouble. Here is what I was working on:

2000 Dodge Durango

Before:

After:

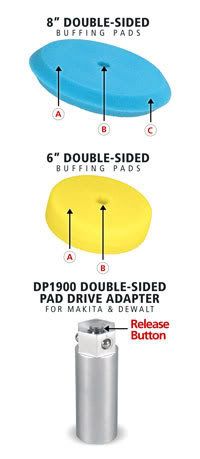

Here is when things went wrong. There is an indention going down the hood on both sides of the front hood emblem and i lifted the rotary at an angle to polish in that crease. That was a big mistake. I swear I smelled the burning right away but was in denial for a second and then it was too late. It is definitely burned right? You can't rub it out and it looks exactly like it "burned" it. Sucks. Thank god it was a hood that I was planning on replacing due to some damage on one side. I was using a black dual sided edge pad 8 In. Double-Sided Foam Pad for Heavy Cutting - Black - DP1910 with some Right Look premium polish Premium Polish - Quart - DC1140-Q

In the end it was my mistake for lifting the pad at an angle but working it at around 1800-2000 I didn't think it would burn like that. Rookie mistake for sure....

Anyone want to trade a Makita Rotary for a DA set or UDM????

2000 Dodge Durango

Before:

After:

Here is when things went wrong. There is an indention going down the hood on both sides of the front hood emblem and i lifted the rotary at an angle to polish in that crease. That was a big mistake. I swear I smelled the burning right away but was in denial for a second and then it was too late. It is definitely burned right? You can't rub it out and it looks exactly like it "burned" it. Sucks. Thank god it was a hood that I was planning on replacing due to some damage on one side. I was using a black dual sided edge pad 8 In. Double-Sided Foam Pad for Heavy Cutting - Black - DP1910 with some Right Look premium polish Premium Polish - Quart - DC1140-Q

In the end it was my mistake for lifting the pad at an angle but working it at around 1800-2000 I didn't think it would burn like that. Rookie mistake for sure....

Anyone want to trade a Makita Rotary for a DA set or UDM????