CalgaryDetail

Mike

We were in for a treat, one of the vehicles was booked for a full detail with paint correction and the other just arrived to Calgary from the US and needed some pampering. The vehicles:

2008 Ford F-550 XLT Super Duty

2004 Ford F-350 XLT Super Duty

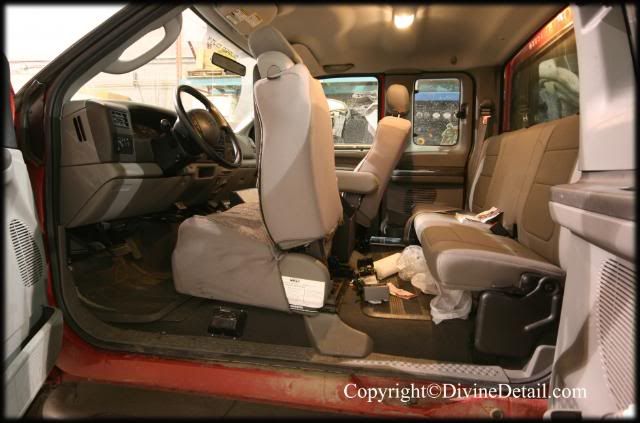

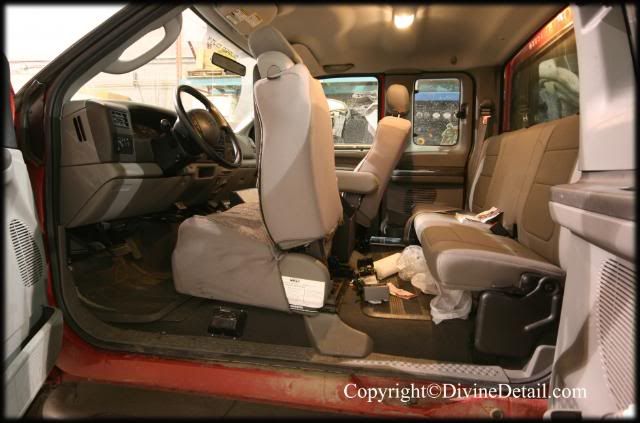

When we arrived the F-550 had not arrived to Calgary just yet so we got started with the F-350, this is what awaited us:

We got started with the interior, all floor mats were removed along with all personal belongings and were set inside a zip loc bag and aside wile we worked in side.

First up was to give the entire interior a wipe down, for the wipe down Meg’s APC diluted with hot water was used along with a yellow micro fiber towel:

With the help of our interior Swissvax brush all vents were detailed:

This is how the wipe down water finished off:

The interior received a good vacuum, once the interior had been vacuumed it was time to use our Mytee extractor:

Now it was time to dress the interior, for this we used Meg’s #40 and applied with the help of a yellow micro fiber towel:

This took care off the interior, it was now time to concentrate on the floor mats, with the help of our Mytee extractor we were able to work on the floor mats:

Here is how the floor mats finished off:

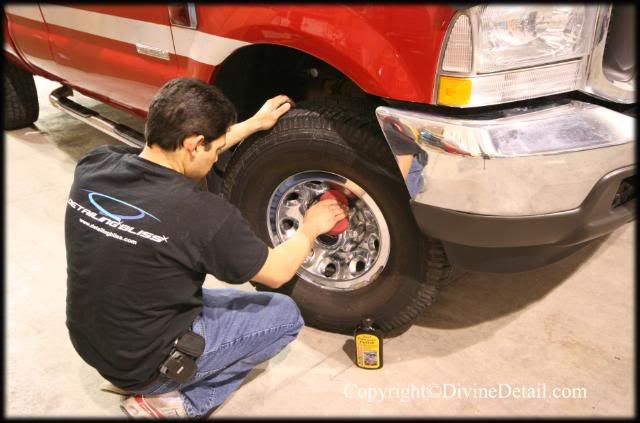

Now for the rims, first all tools were gathered:

Now first up were the wheel wells, for the wheel wells P21S Total Auto Wash was applied:

For the face of the rims P21S Gel was applied:

For the tires, ARO was used:

Now it was time to agitate the wheel wells, with the help of our Meg’s long handle brush we scrubbed the wheel wells:

Once the wheel wells were agitated to satisfaction it was time to agitate the face of the rims, this was done with the help of our Swissvax brush:

Once the face of the rims were agitated to satisfaction it was time to move on to the tires, for the tires we used our new tire brush:

This was the process to all the rims, tires and wheel wells on this truck.

Moving along it was now time for the rest of the exterior of the truck, first we connected our CR System to obtain pure De-ionized water:

2008 Ford F-550 XLT Super Duty

2004 Ford F-350 XLT Super Duty

When we arrived the F-550 had not arrived to Calgary just yet so we got started with the F-350, this is what awaited us:

We got started with the interior, all floor mats were removed along with all personal belongings and were set inside a zip loc bag and aside wile we worked in side.

First up was to give the entire interior a wipe down, for the wipe down Meg’s APC diluted with hot water was used along with a yellow micro fiber towel:

With the help of our interior Swissvax brush all vents were detailed:

This is how the wipe down water finished off:

The interior received a good vacuum, once the interior had been vacuumed it was time to use our Mytee extractor:

Now it was time to dress the interior, for this we used Meg’s #40 and applied with the help of a yellow micro fiber towel:

This took care off the interior, it was now time to concentrate on the floor mats, with the help of our Mytee extractor we were able to work on the floor mats:

Here is how the floor mats finished off:

Now for the rims, first all tools were gathered:

Now first up were the wheel wells, for the wheel wells P21S Total Auto Wash was applied:

For the face of the rims P21S Gel was applied:

For the tires, ARO was used:

Now it was time to agitate the wheel wells, with the help of our Meg’s long handle brush we scrubbed the wheel wells:

Once the wheel wells were agitated to satisfaction it was time to agitate the face of the rims, this was done with the help of our Swissvax brush:

Once the face of the rims were agitated to satisfaction it was time to move on to the tires, for the tires we used our new tire brush:

This was the process to all the rims, tires and wheel wells on this truck.

Moving along it was now time for the rest of the exterior of the truck, first we connected our CR System to obtain pure De-ionized water: