pic of the car:

There is still some adaption work.

]

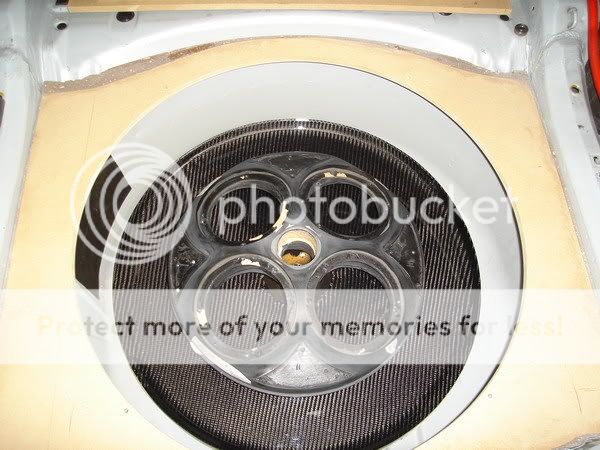

This will be the Sub-box.

The piece I wanted to cover in Carbonkevlar, I painted black, to be sure the layer underneath won't show.

milled some rings to put the woofers in.

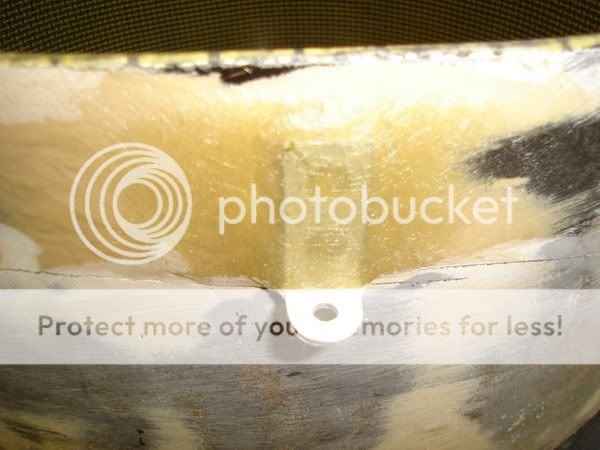

Here a picture of the bottomside, where he made wholes , to let the sound flow outside.

Still some more polyester work to do.

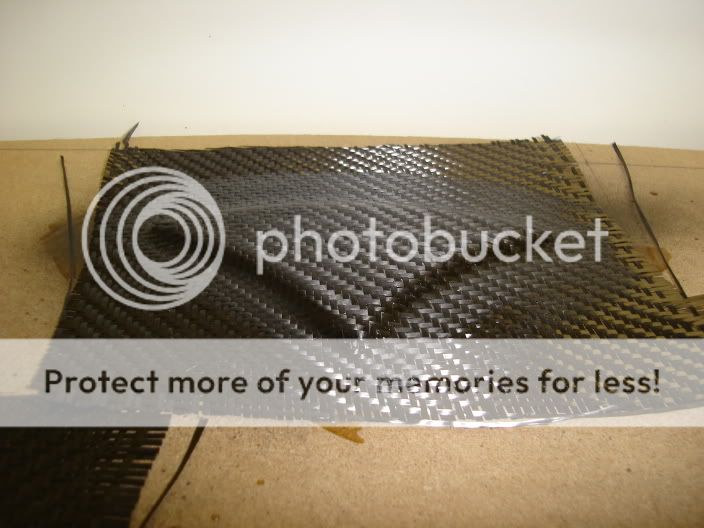

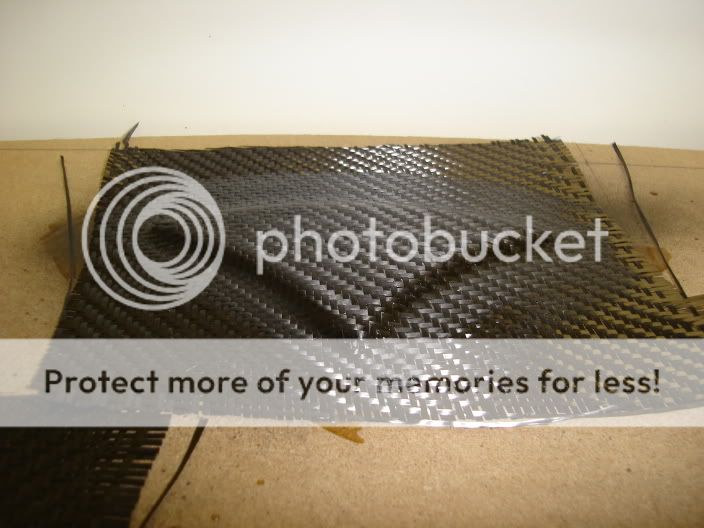

Did some preparation to stretch the cloth nicely.

The wholes you can see in the alu, don't worry about it.

It'll be covered in CF..

The next thing on the list is something very difficult.

The connections of the speakers he'll make in copper, of 5mm thickness.

Cables are so boring

some cupper

5mm thickness, more didn't fit in the speaker.

Copper connections are ready.

made a model first, took a mold, and fold it the same way.

Sawed it all, rubbed it, and polished.

On this picture you can see he putt a whole in the bottomside to connect the cables.

The cupper wil go to the middle, so I made a alu plated where the bars fitt right on in.

alu triangles bade in a little CF.

some more CF.

This is the bottom plate where the box is put on.

sprayed it in black offcourse, don't want the colour of the wood come throu

Varnished it for the first time, rubbed some more, varnished, rubbed, varnished, rubbed, ...........

There is still some adaption work.

]

This will be the Sub-box.

The piece I wanted to cover in Carbonkevlar, I painted black, to be sure the layer underneath won't show.

milled some rings to put the woofers in.

Here a picture of the bottomside, where he made wholes , to let the sound flow outside.

Still some more polyester work to do.

Did some preparation to stretch the cloth nicely.

The wholes you can see in the alu, don't worry about it.

It'll be covered in CF..

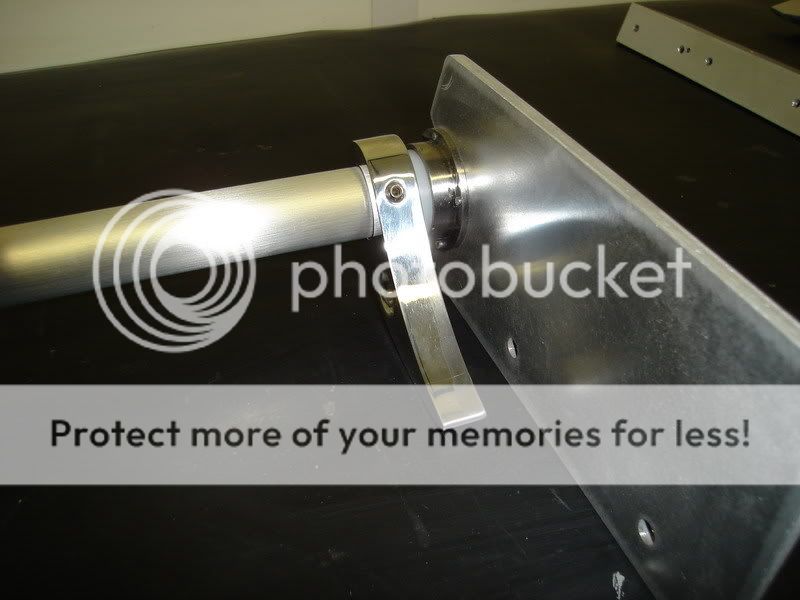

The next thing on the list is something very difficult.

The connections of the speakers he'll make in copper, of 5mm thickness.

Cables are so boring

some cupper

5mm thickness, more didn't fit in the speaker.

Copper connections are ready.

made a model first, took a mold, and fold it the same way.

Sawed it all, rubbed it, and polished.

On this picture you can see he putt a whole in the bottomside to connect the cables.

The cupper wil go to the middle, so I made a alu plated where the bars fitt right on in.

alu triangles bade in a little CF.

some more CF.

This is the bottom plate where the box is put on.

sprayed it in black offcourse, don't want the colour of the wood come throu

Varnished it for the first time, rubbed some more, varnished, rubbed, varnished, rubbed, ...........