Concours.John

Auto Detail & Restoration

This particular vehicle was a promotional vehicle for the Ronald McDonald house charities. It was on display at a local Porsche museum and at multiple shows and events. The vehicle was repainted several years ago. It used to have multi-colored hand prints all over. These were removed before it was purchased by the current owners. There were still “shadows” of some of them when I received it. I have been fortunate to work with them on other projects in their collection.

The vehicle is covered with shrinkage pretty deeply, swirls and scars from the hand print removal. Whatever was used to remove the handprints has tinted the clear. With this being a repaint over the original paint and primer between, a common sense approach is necessary. I will not be able to gauge the clear coat except by using the experience of following behind multiple painters habits of spraying. Careful judgment and visual inspections were used throughout.

The Goal is to save this vehicle from a repaint if at all possible. The outside of the vehicle came in clean other areas received a good wash/rinse where components were removed.

PROCESS

Underside and wheel wells were washed with Simple Green and Griots car wash 2oz. to 2gal.

After washing areas where components were removed the vehicle was fully clayed with Griots Speed Shine and Griots Paint Clay.

The majority of the vehicle was sanded w/ 3M 2000 grit followed by 3M Trizact 3000 foam sanding disks.

I wanted to see what the Megs MF Correction System was really capable of compound wise. Menz. PO85rd was used with the finishing disk.

Compounding PC7424xp 4800opm per instructions

Polishing PC7424xp just below 4800opm the Po85rd seemed to like it here

70% ISO clarity checks were done between each step before a final burnishing with the Po85rd

A final ISO wipe down before sealer was applied this is why I chose not to use the D301

OBSERVATIONS

The D300 required a few extra passes but did remove the sand marks with the aid of the Trizact. Keeping the pad clean is a must. Compressed air worked best but made a mess. A test spot to compare speed was done with LC orange and Menz. Power Finish on a rotary at around 1800rpm. The rotary accomplished this with fewer passes. This would have been followed with LC black and Po85rd to insure gloss. My main objective was to show what the Megs system can do in comparison. This would also be less aggressive with less chance of error. Speed=rotary Safe correction=DA Meg system.

This paint was relatively hard also.

All final pictures including outside were before sealer. Any high quality sealer would work. If you use the D301 an ISO wipe down is necessary to remove the built in wax to insure a good bond.

All edges were taped then back taped before proceeding to next panel. All black foam components were protected. Tape was removed for documentation and wipe downs.

PAINT CONDITION

UNDERSIDE

PREP AND PROCESS

YOU CAN SEE THE DIFFERENCE IN SHADE HERE, FENDER DONE HOOD NOT

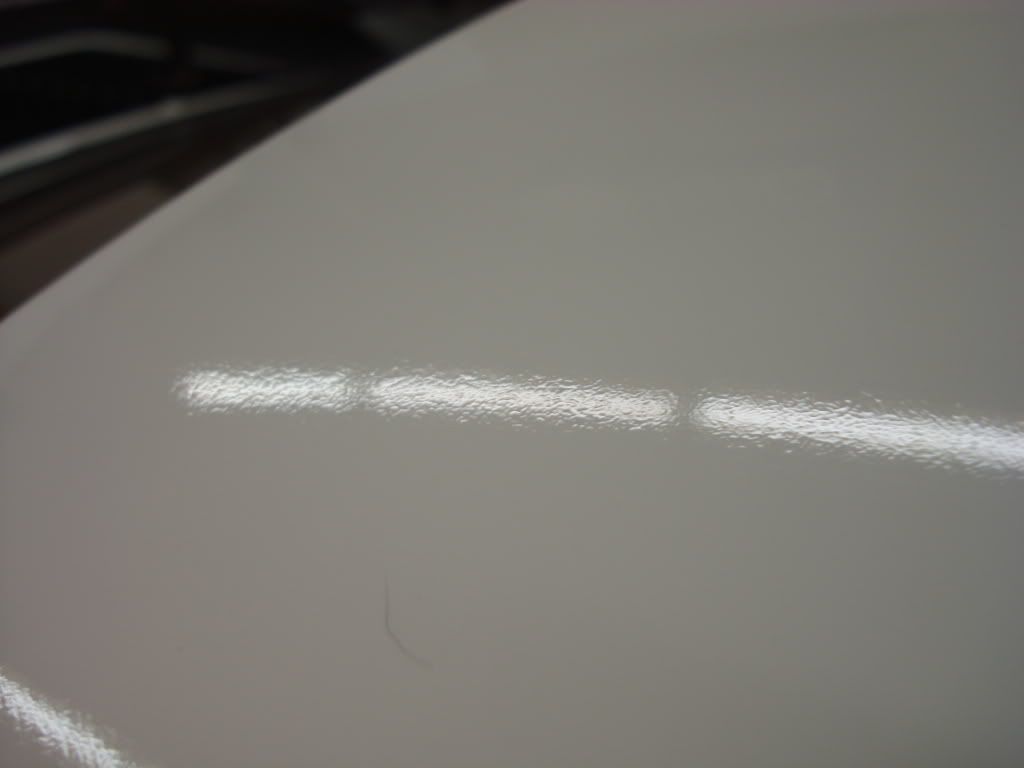

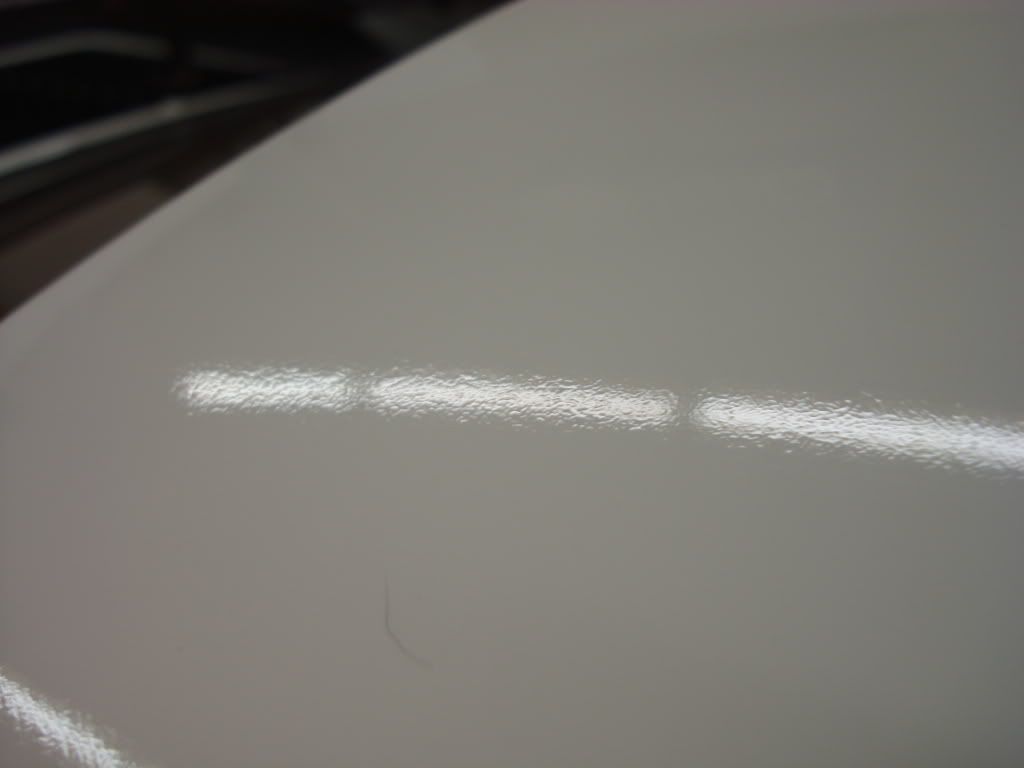

SHRINKAGE THAT WAS REMOVED GOES TO EDGES IN PLACES

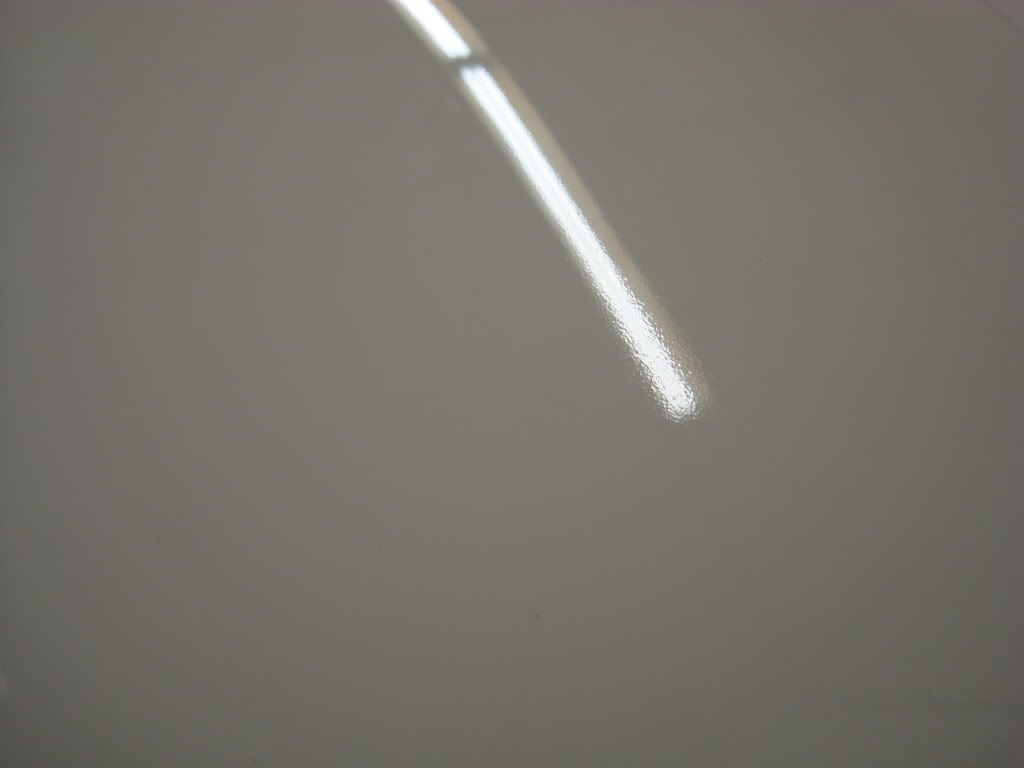

AFTER

ROOF

BOTTOM

SUN PEEKING THROUGH CLOUDS

THANKS FOR LOOKING.

I read Todd's great write up on the Veyron while waiting for pictures to load. I definitely have alot to learn about doing this.

The vehicle is covered with shrinkage pretty deeply, swirls and scars from the hand print removal. Whatever was used to remove the handprints has tinted the clear. With this being a repaint over the original paint and primer between, a common sense approach is necessary. I will not be able to gauge the clear coat except by using the experience of following behind multiple painters habits of spraying. Careful judgment and visual inspections were used throughout.

The Goal is to save this vehicle from a repaint if at all possible. The outside of the vehicle came in clean other areas received a good wash/rinse where components were removed.

PROCESS

Underside and wheel wells were washed with Simple Green and Griots car wash 2oz. to 2gal.

After washing areas where components were removed the vehicle was fully clayed with Griots Speed Shine and Griots Paint Clay.

The majority of the vehicle was sanded w/ 3M 2000 grit followed by 3M Trizact 3000 foam sanding disks.

I wanted to see what the Megs MF Correction System was really capable of compound wise. Menz. PO85rd was used with the finishing disk.

Compounding PC7424xp 4800opm per instructions

Polishing PC7424xp just below 4800opm the Po85rd seemed to like it here

70% ISO clarity checks were done between each step before a final burnishing with the Po85rd

A final ISO wipe down before sealer was applied this is why I chose not to use the D301

OBSERVATIONS

The D300 required a few extra passes but did remove the sand marks with the aid of the Trizact. Keeping the pad clean is a must. Compressed air worked best but made a mess. A test spot to compare speed was done with LC orange and Menz. Power Finish on a rotary at around 1800rpm. The rotary accomplished this with fewer passes. This would have been followed with LC black and Po85rd to insure gloss. My main objective was to show what the Megs system can do in comparison. This would also be less aggressive with less chance of error. Speed=rotary Safe correction=DA Meg system.

This paint was relatively hard also.

All final pictures including outside were before sealer. Any high quality sealer would work. If you use the D301 an ISO wipe down is necessary to remove the built in wax to insure a good bond.

All edges were taped then back taped before proceeding to next panel. All black foam components were protected. Tape was removed for documentation and wipe downs.

PAINT CONDITION

UNDERSIDE

PREP AND PROCESS

YOU CAN SEE THE DIFFERENCE IN SHADE HERE, FENDER DONE HOOD NOT

SHRINKAGE THAT WAS REMOVED GOES TO EDGES IN PLACES

AFTER

ROOF

BOTTOM

SUN PEEKING THROUGH CLOUDS

THANKS FOR LOOKING.

I read Todd's great write up on the Veyron while waiting for pictures to load. I definitely have alot to learn about doing this.